SAFETY

GUIDES

for the operation

of

CARBIDE

TIPPED

SAW BLADES

Read Completely Before Attempting To Operate Carbide Tipped Saw Blades

This leaflet of safety and

operating

instructions

is

not

intended to

be

and

is

not

totally comprehensive: that is. it

does not, and cannot. cover every

possible safety problem

which

m11y

arise in using specialized and standard

tooling on varying machines and

applications.

This

leaflet is

rather

intended to generally describe

many

of

the basic safety and operating

procedures which should be followed,

and

to

describe the types

of

safety

considerations

which

should

be

considered in operating

cutting

tools

.

None

of the statements

or

information

presented in this leaflet

should

be

interpreted

to

imply

any

warranty

or

safety

protection.

The drawings

do

not

depict

any

particular design, type,

or

size

of

tools.

equipment

or

machines.

The

drawings

are illustrative

only

and

are

not

to

be construed to establish

any

exact mode,

method

or

procedure

.

All Federal and State laws and

regulations having

jurisdiction

covering the safety requirements

of

cutting

tools at

the

point

of

usage take

precedence over the statements

and

information

presented in this leaflet.

Users

of

cutting

toots

must

,

of

course,

adhere to all such

regulations

. As an

aid to

cutting

tool

users a

number

of

such regulations are listed

below

. The

list does not

include

all

regulations

that may apply:

1. The Federal Register dated

June

27,

1974, Dept.

of

Labor,

Office

of

Safety

and Health

Administration

(The

OSHA Act)

2. American National Standards

In-

stitute,

01

.1-1975 (Safety Regu-

lations for Woodworking Machinery)

3. American National Standards In-

stitute,

02

.1-1969 (Safety Require-

ments for Sawmills)

4. American National Standards In-

stitute,

P1

.1-1969 (Safety Require-

ments for Pulp, Paper and Paper-

board Mills)

5. Other ANSI, State and/

or

Federal

Codes and Regulations

which

may

apply in

your

operation

SAFETY RULES WHICH APPLY TO

THE OPERATION

OF

ALL

CARBIDE

TIPPED CUTTING TOOLS

1. Always inspect the

cutting

tool

completely before

mounting

. Never

attempt to operate a

tool

which

has

chipped or bent teeth or

cutting

edges

or teeth that are

not

sharp. You

must

be familiar

with

normal wear

conditions

for the type

of

tooling

to be

used. The

tool

must be

completely

clean to allow

proper

visual

inspection.

2.

Do not

attempt

to operate

cuttfng

tools

or

machinery

with

which

you

are

not

familiar

or have

not

received

operational

training-get

assistance

from

your

supervisor.

his

designated

representative

or

a trainer

who

is

familiar

and

properly

trained

and

eKperienced

on

the

machine

to

insure

your

safety.

Become

completely

familiar

with

all

of

the

machinery

manufacturer

's

written

instructions

,

guides and manuals before

operating

machine

. You

must

use and be

familiar

with

all

controls

, safety devices and

emergency

stop

mechanisms

to

operate a

machine

safely.

3.

Never

operate

a

cutting

tool

that

is

not

properly

aligned

to

the

direction

of

feed. Do

not

allow

sideward,

twisting

or

other

than

forward

pressure on

the

cutting

tool

in feeding material

into

a

cut

.

c.

Make sure

the

tool

is

mounted

to

rotate in the

proper

direction

before

cutting

any material. The

tool

must

rotate against. rather than with,

the

direction

of

feed

on

all hand feed

machines.

Do

not

climb

on

hand feed

machines.

5.

Do

not

cut

materials

of

a type,

hardness'

or

density'

other

than

that

which

the

cutting

tool

was designed

to

cut. Never

attempt

to

cut

materials

with

a

tool

unless

you

have personally

checked

with

your

supervisor

to

make

sure the

cutting

tool

was designed

for

the

specific

type

of

material

you

wish

to

cut, and

for

the

depth

of

cut

desired.

This

is

particularly

important

when

attempting

to

cut

"stacked" material,

i.e

.,

cutting

more

than one piece at a

time

.

6. Never force-feed materials

into

a

cutting

tool

such that it causes

the

toot

or

machine

motor

to

slow

down

below

operating

speeds. A safe and

proper

cutting

operation

will not require

much

force

in feeding material. If

material begins

to

"ride

up

" on the

cutting

tool, or requires

undue

pressure to feed the material i

nto

the

tool

,

or

if

undue

vibration is

experienced.

do

not

cont

inue the

cut-turn

off

all

power

and correct the

condition

.

7.

l<.eep

body

and

clothing

well clear

of

all

cutting

tools

and other

moving

parts while the machine is in

operation. Use

work

holding

fixtures

and mechanical feed devices in all

possible cases. When

cutting

material

of

such size. shape or type that it

necessitates close

approximation

to

the

cutter

and

mechanical

feed

1. Hardness is the resistance of a

materi

al

to

being

cul

or the

strength

of a materi

al

to

res

i

st

tearing or

breaking .

2. Density

is

the compactness of a

material compared to its volume.

mechanisms

cannot be used, use a

wood

"

push

stick"

to

feed the material

so

that

no

part

of

your

body

or

clothing

comes close

to

the

cutting

tool

.

a. Never attemp

to

clean a

cutting

tool

or

clear pieces

of

material from

the

cutting

area while

machine

power

is

"

on"

or

when

cutting

tools, material

or

any

part

of

the

machine

is

moving.

Allow

cutter

rotation

to

stop

by

itself,

or

by use

of

a brake if

supplied

on th!!

machine

. Never

attempt

to

stop

or

slow

a

rotating

cutting

tool

by

applying

a hand-held

or

any

other

object

to

the

cutter

.

arbor

, spindle

or

drive as a brake.

I. Do

not

ptace

your

body

in the

rotational

path

of

a

cutting

tool

unless

absolutely

necessary, and then only

ii

there is a

complete

and adequate

barrier

between you and the

cutting

tool. Remember that carbide tips are

very

hard

and, therefore,

brittle

. The

tips can break away

under

incorrect

side

thrust

or

twisting

forces,

or

if

foreign

material

is

allowed

to

contact

the

tips

. An

operator

can reduce the

danger

of

being hurt

by

a

"kickback"

of

the material if he always stands

bealde

the

material he is feeding

into

the

machine

rather than in back of it.

10. Never leave machines unattended

while

cutting

tools are still rotating

or

any part

of

the machine

or

material is·

moving

.

11. Never operate a

machine

without

using all

of

the hoods,

guards

,

hold-

downs

and

safety devices

for

the

machine

being operated.

12.

Machines

must

be

maintained

to

the

manufacturer's

standards and

current

safety standards.

13. Always wear safety glasses or face

shield

to

completely

protect

your

eyes

when

operating

cutting

tools.

CIRCULAR

SAW

BLADES AND

SAW MACHINE TOOLS

MOUNTING

INSTRUCTIONS

1. TURN OFF AND

LOCK

OUT

ALL

MACHINE

POWER. Clean the saw

arbor, saw collars, sleeve and arbor

nut. Remove nicks and burrs by very

lightly

honing

any nicked or burred

area. (Do

not

use coarse files or

abrasives).

2.

WITH

ALL

MACHINE

POWER OFF

AND

LOCKED

OUT,

pull

and

push

on

the

machine

arbor sideways in and

out

by hand (

without

rotating the arbor).

There

should

be no feeling of

movement. Next. rotate the arbor by

hand. If

the

bearings are in

proper

conditi

on

.

the

arbor

should

turn

freely

with

no

sticking

or

rubbing

.

To

check

the

arbor

, set up a dial

indicator

as

shown

in Fig. 1. The

arbor

should run

true

with

in the

motor

manufacturer's

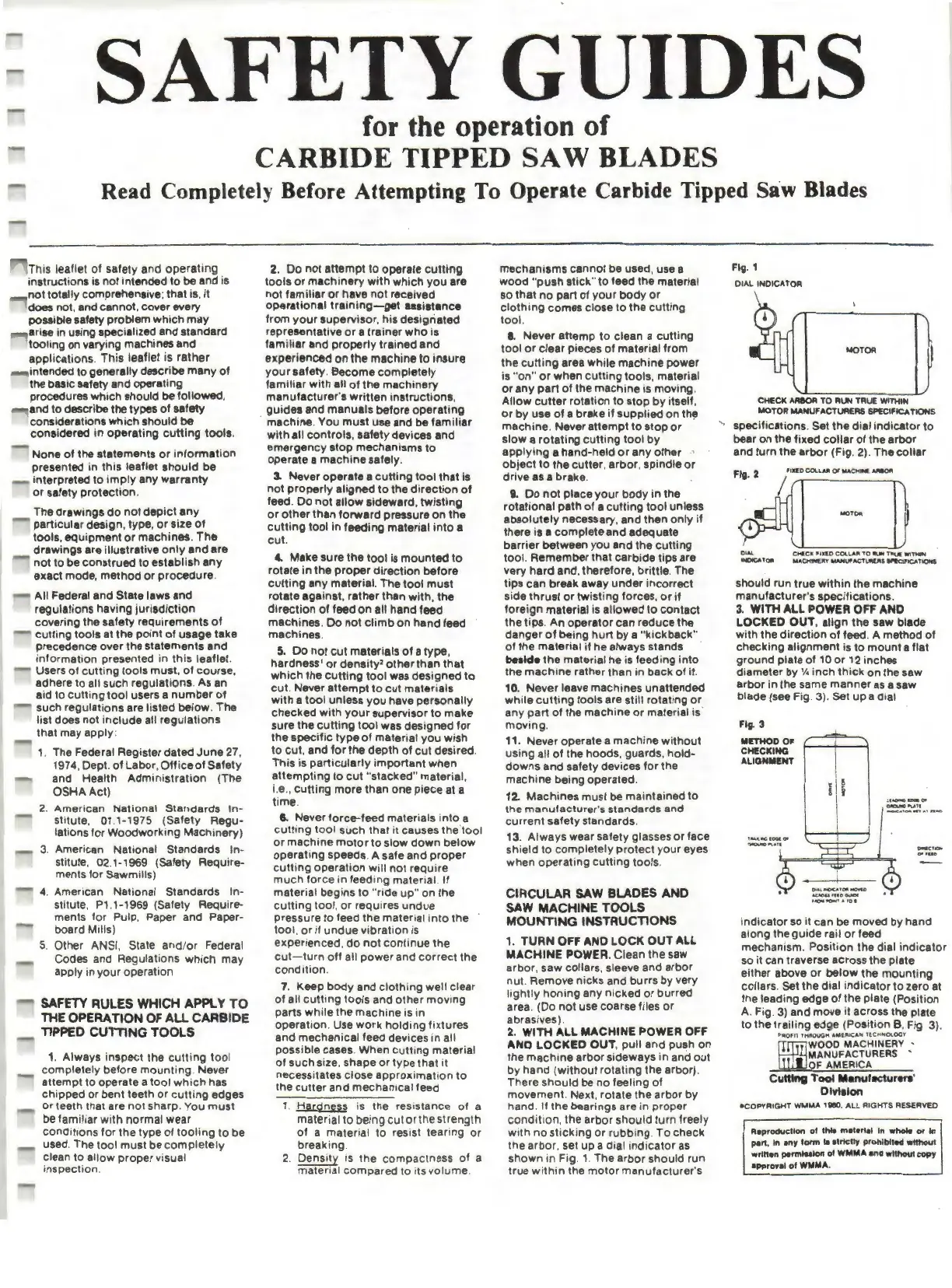

Fig. 1

0 1

._

l INDICATOR

MOTOR

CHECK ._RllOR TO RUN TRUE

WITHIN

MOTOR MANUF•CTUAERS SPECIFICATIONS

.

.,

specifications. Set

the

dial indicator

to

bear on the fixed

collar

of

the arbor

and turn the arbor (Fig. 2). The collar

Fig. 2

flXfO cou

...

ui

OJ

MA

C

HN.

~

I

MO

TOO

OIAl CHI.CK FIXED

COll,.Att

'TO RUN TlllU( WITMIN

INOtCATOfll MACMIN£R'T

MAHUfACT'-""CRS

IW'EO'ICATIC>Mi

should run

true

within

the machine

manufacturer's specifications.

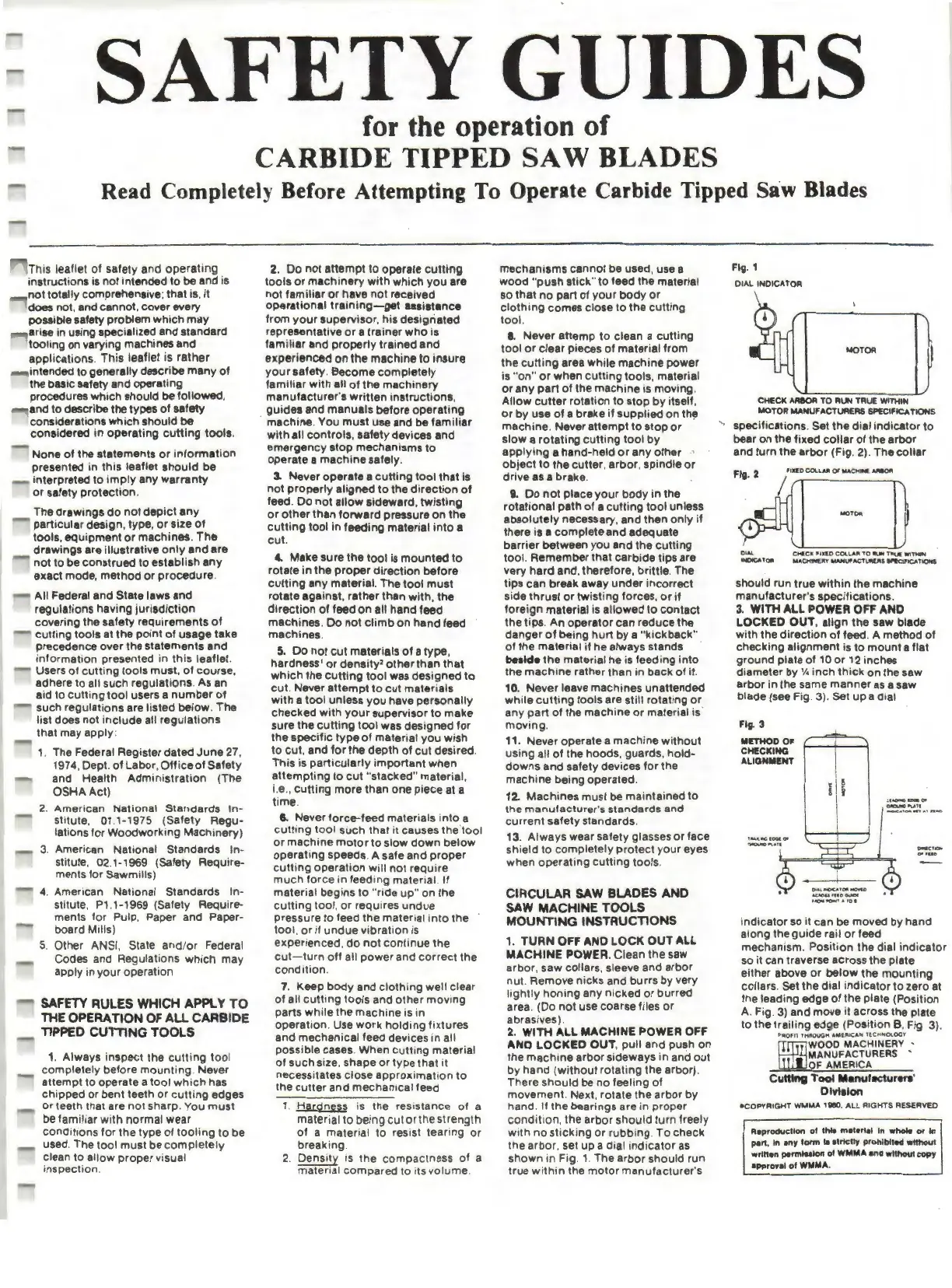

3.

WITH

All

POWER OFF

AND

LOCKED OUT,

align

the

saw blade

with the

direction

of

feed. A method

of

checking alignment is

to

mount

a flat

ground

plate

of

10

or

12

inches

diameter by

V.

inch

thick

on

the saw

arbor in the same

manner

as

a saw

blade (see Fig. 3). Set

up

a dial

Fig. 3

METHOD

0,

CHECKING

ALIGNMENT

~l

aootC.

lOGt

00

GlllCIUe"Votl

-...~-~

.. •

nOC>

indicator so it can

be

moved by hand

along the guide rail

or

feed

mechanism. Position the dial

indicator

so

it can traverse across the plate

either above or below the

mounting

collars. Set the dial

indicator

to

zero at

the leading edge

of

the plate (Position

A. Fig.

3)

and move it across the plate

to the trailing edge (Position

B,

Fig

3)

.

PROFll

THROUGH AMERICA,,.

TlCHNOlOG'I'

WOOD MACHINERY •

MANUFACTURERS '

OF AMERICA

Cutting

Tool

Manufacturers'

Dlvlalon

•COPYRIGHT

WMMA

HBO.

ALL

RIGHTS

RESERVED

A•productlon

ol

tttt.

m•tertal

In whole

or

In

port,

In

ony torm

11

1lrtctly prohlbtto•f without

wrlHon pormlsalon ol

WMMA

and

without copy

approwel

of

WMMA.

Loading...

Loading...