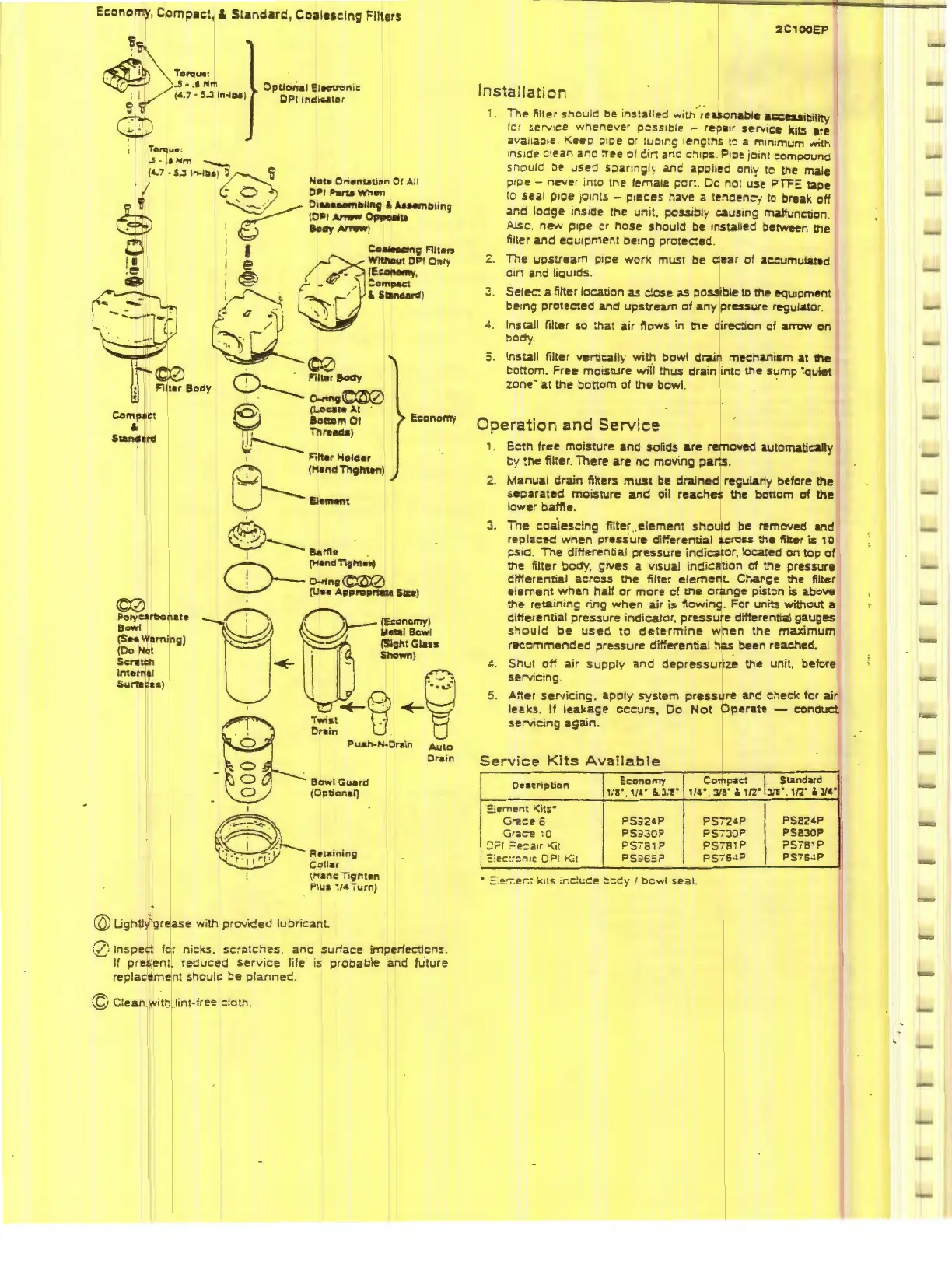

Economy, Compact, & Standard, Coalescing

Filters

lorqu•

:

~

.

/s~;"1

...

1~~i

· ;

"b

-

Not•

O"anution

Of

.I.I

I

CPI

Pana

When

Oi•HNfTlllllng

At

A&Mmblin;

!CPI

Ar"11W

Opl'Uil•

Body...,._,

~

~

r

0 I I

Co-n11

Fllt•rs

I• I e

@WltnoutOP!Onty

. e .

~

$i

•

fE&:clftOmy,

9 I

'-e'

- / CompaC1

~Q0c.-.:~.

-·

~

i

(J

. -·

~

,

lStanoard

)

-·

· ( . /

..

· -···

·..

~

·

-

t

oo

0

·

~Body

Compac:t

'

Standud

Filler

Body

·

---

1

O..l'ift9~

(L.ogta

Al

·

Bollom

01

Tllr•ad•)

r---._

1 Fitter Holclar

M_

(HandThghten)

U----

Element

~~

~---

1

s.m.

.

0-nn;~

Economy

CD-

{MandT191tt•n)

.

(tJ••

Appropriate

Sin)

©:Zl

Potyearbcnate

Bowl

(SHWaming)

(Do Not

Scratch

Internal

SLOr1aCts)

I

~

~~,___

FloLaining

~

C.:illar

I

(Hand

TiglHan

PILOI

1/<I

Turn)

@ UghtJy:grease with

provided

lubricant.

,7

'.

lnspec

fer nicks.

sc~atc~es

,

and

surface

imperfecticns.

"-'

If

present.

reduced

service

life

is

prooat:le

and

future

replacement

should

t:e

planned.

©

c:ean

witlJ lint-free c!

oth

.

Installation

1.

1'1e

nite r snoul

C:

t:>e

i

nstal

led

w1tn

.

reuonable

accessibility

rcr

se

rvice

wneneve

r

pcss

1ble - repair service kits are

ava

11

ao1e

Keeo

p1oe or

tuc

1

n~

lengths

to

a minimum

with

s1oe : 1ean and

~ee

of

d111

ana

cn1ps

. Pipe joint comoouno

s

ri

ou1c

:ie

usea

soaring

ly

anc

apclred only

to

trie male

01pe -

neve

r

~

nto

tne female i;:er:. Do not use PTFE !3pe

to

sea1

p1oe

10

1nts - 01eces have a tenoency

to

break oft

;ar.o

l

odge

1ns1oe

the unrt. possibly causing maltvnct1on.

Alsc

new

p1oe

er

nose

should

be rnstaJled

betw~n

trie

filter and

equipment

oe1ng protec:ed.

<-

.

The

upstream

p1

ce

work

must be

dear

of ac:eumulated

c1n

and liquids.

:;

. Selec: a lilter l

ocauon

as

dcse

as possible to the equipment

being

proteeted

and

upstream

of

any

pressure regulator.

4 . Install filter so :nat air

nows

in

!tie

direc:ion

of

arrow on

tlcdy

.

• . Install

filter

vertcally

with

bowl drain

mechanism

at the

bottom

. Free

moisrure

will

thus

drain

into the sump '.quiet

zone·

at

tne

bonom

of

the

bowl. I ·

Operation

and

Service

1.

Seth

tree

moisture

and solids are removed automatically

t:y

!he

filter.

There

are

no

moving

par.s.

2.

Manual

drain

filters

must

be

drained

regularly before the

separated

moisture

and

oil

reaches

the

bottom

of the

lower

baffle

.

3.

Tne

coalescing

filter

..

element

should

be removed and

replaced

when

press

.

ure

dif:erential

ai;ross the filter 'i$ 1 O

psid

.

The

differential

pressure

indicator,

located on

top

of

tne filter bedy. gives a visual

indication

of

the pressure

dir.erential

across

the

filter

element.

Ct-.ange the filter

element

when

half

or

more

cf

the

orange

piston is a.bove

the retaining

ring

when

air is 11owing. For units without a

differential

pressure

indicator.

pressure

differential gauges

should

be

used

to

determine

when

the

maximum

r1PCommended

pressure

differential

has

been

reached

.

~

.

Shut

or.

air

supply

and

depressur

i

ze

the

unit

, before

servicing.

5. At:er

ser1icing.

apply

system

pressure

and check for air

leaks

. It

leakage

occurs,

Do

Not

Operate

-

conduct

servicing

again.

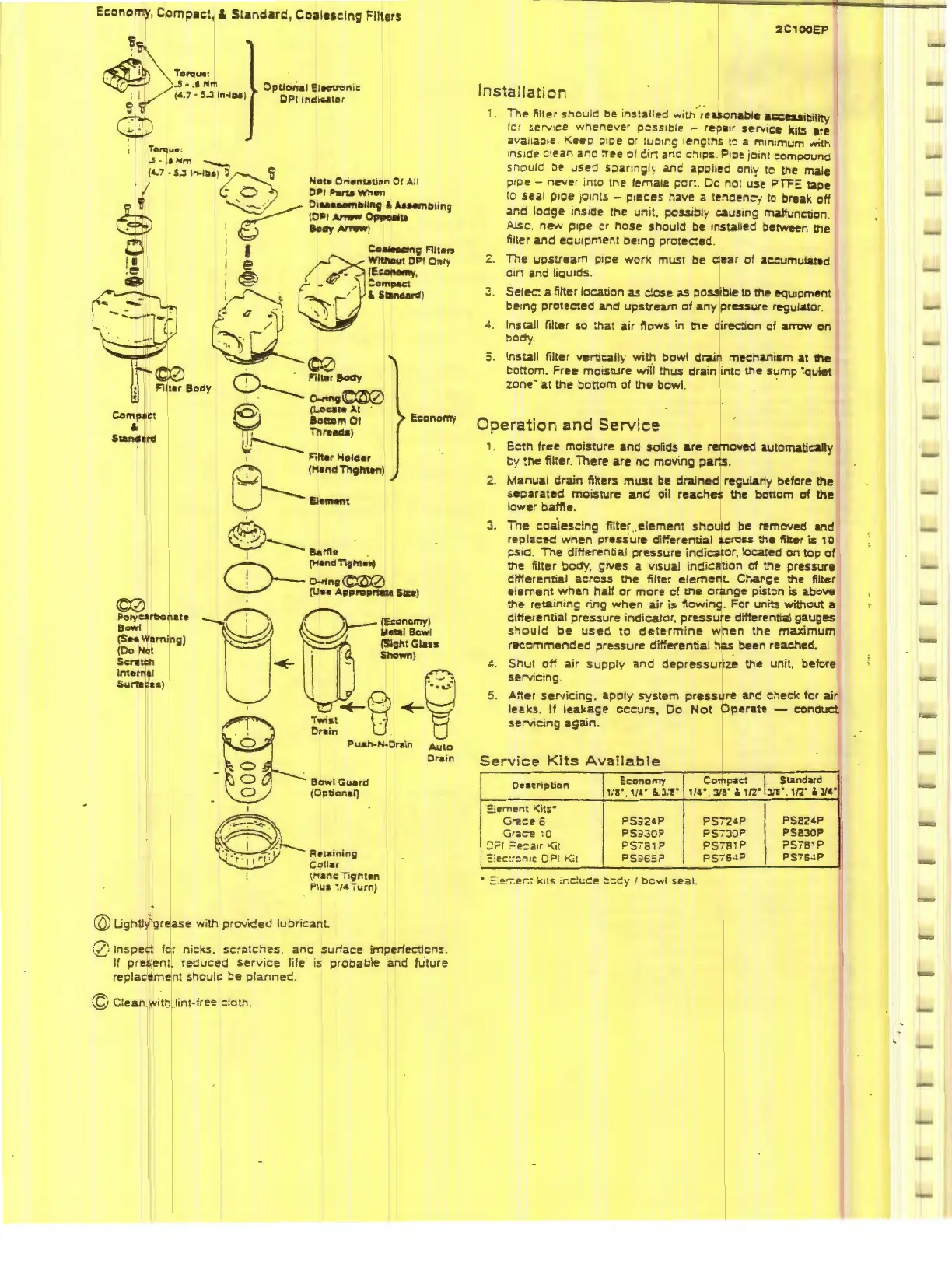

Service

Kits

Available

Cescriplion

Economy

Compact

Standard

1;s·.

114

•

&.

:i

:s·

1/4·.

318"

a.

i12·

:li!"

.

112"

AtJW

: :ement '<its•

Grace

5

Ps;24P

PS724P

PS824P

Grace

~

O

I

PS3:00P

PS7::!0F

PSBJOP

:;;:

1

:=2::a1

r

\(i

t

PS781P

PS781P

?5781

p

:O

·

ec

:

c:nic

O Pi Kit

PS365?

PS75~?

PS75-iP

•

:0

".

eT er::

~

It

s

:r

.c!wce

~::;cy

/ bowl seal.

Loading...

Loading...