EN

20

WIKA operating instructions, models TRxx and TCxx

14150915.08 04/2024 EN/DE/FR/ES

5.4.3 Tightening torques for the thermometer

■

Only ever screw in, or unscrew, the instrument via the spanner flats and to the

prescribed torque using an appropriate tool.

■

The correct torque depends on the dimensions of the connection thread and the seal

used (form/material).

■

When screwing in or unscrewing the instrument, do not use the connection head as

contact surface.

■

When screwing in the instrument, please observe that the threads are not crossed.

■

NPT threads to the head must not be loosened by the customer. A PTFE/PFA

lubricant is applied at the factory to the NPT threads to the thermowell/protection

tube. This must be renewed if the threads are loosened by the customer.

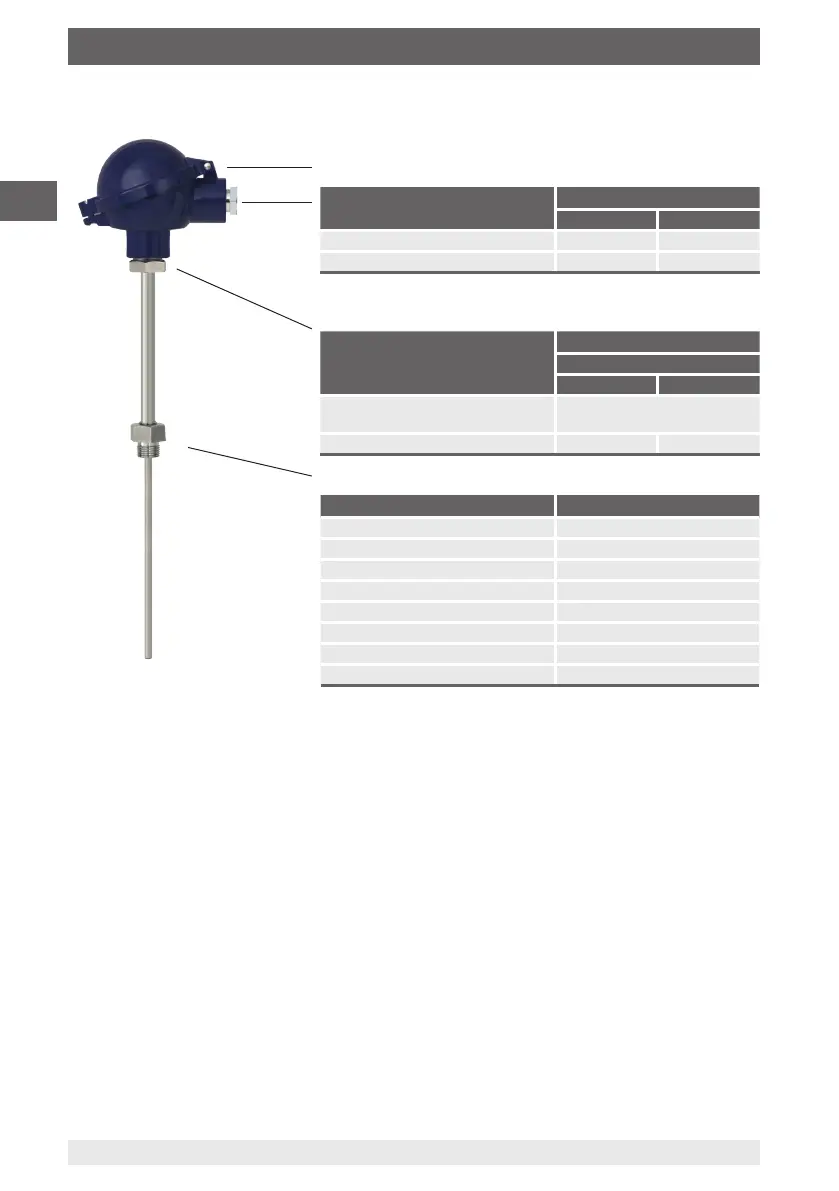

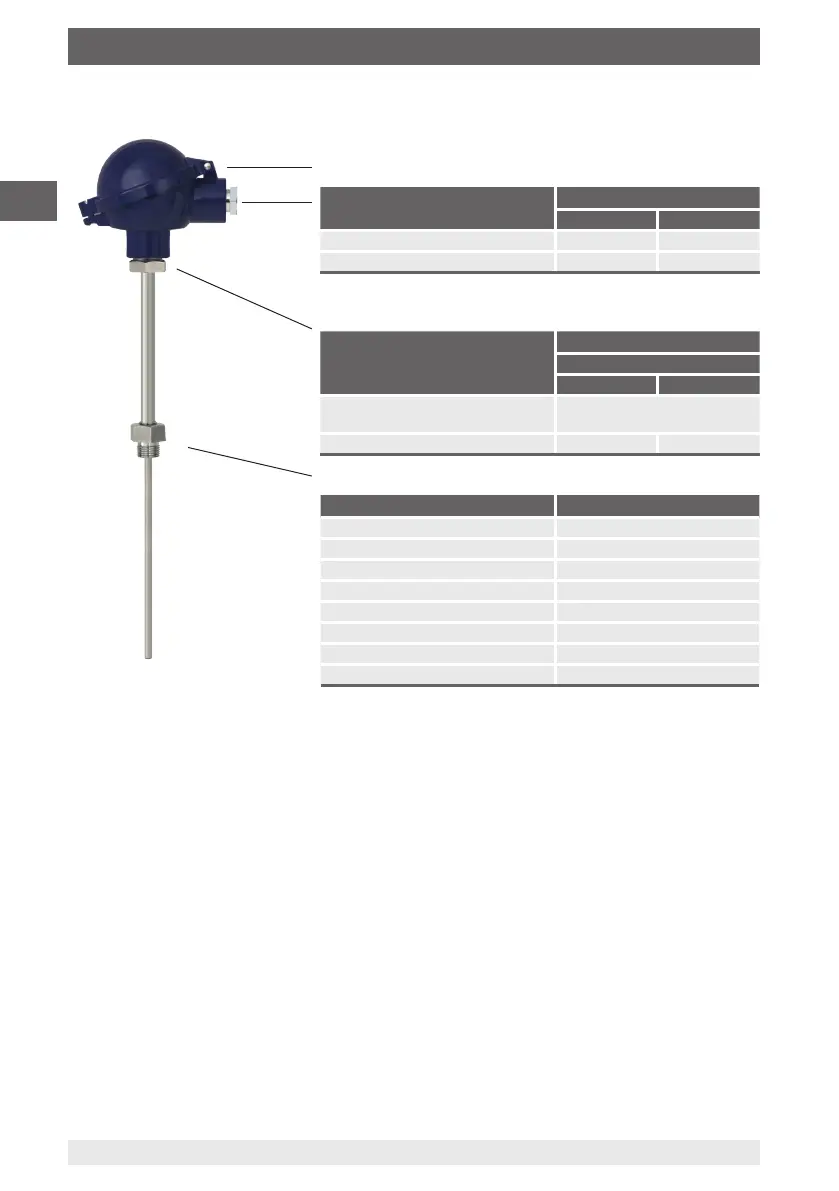

Connection head

BS, BSZ, BSZ-H, BSS, BSS-H, BSZ-K, BSZ-HK, KN4-A)

Figure shows the BSZ connection head

Threads Tightening torques

Connection head material

Aluminium Stainless steel

½ NPT The connection must not be

disconnected by the user.

M24 x 1.5 with male nut 27 Nm 30 Nm

Tightening torques between connection head and neck tube

Tightening torques for connection to thermowell/protection tube

Threads Tightening torques

½ NPT 30 Nm

¾ NPT 40 Nm

G ½ B 35 Nm

G ¾ B 40 Nm

M14 x 1.5 27 Nm

M18 x 1.5 35 Nm

M20 x 1.5 37 Nm

M27 x 1.5 42 Nm

5. Commissioning and operation

Threads Tightening torques

Metal Plastic

M20 x 1,5 20 Nm 12 Nm

½ NPT 20 Nm T. F. F. T 2-3

1)

1) Turns from finger tight (T.F.F.T)

Loading...

Loading...