English

14 WILO SE 09/2008

7 Installation and electrical connection

DANGER! Risk of fatal injury!

Incorrect installation and improper electrical

connections can result in a risk of fatal injury.

• The installation and electrical connections

should only be done by properly skilled staff and

in compliance with the applicable regulations!

• Follow all accident prevention regulations!

7.1 Installation

The pump is designed for stationary or transport-

able installation.

CAUTION! Danger of property damage!

Danger of damage due to incorrect handling.

Only suspend the pump by the strap with the aid

or a chain or rope, never by the electrical or float

switch cable or the pipe/hose connection.

The installation site or shaft for the pump must be

free of frost.

The shaft must be cleared of coarse material such

as rubble before setting up and starting the pump.

The quality of the shaft must guarantee the

unhindered mobility of the float switch.

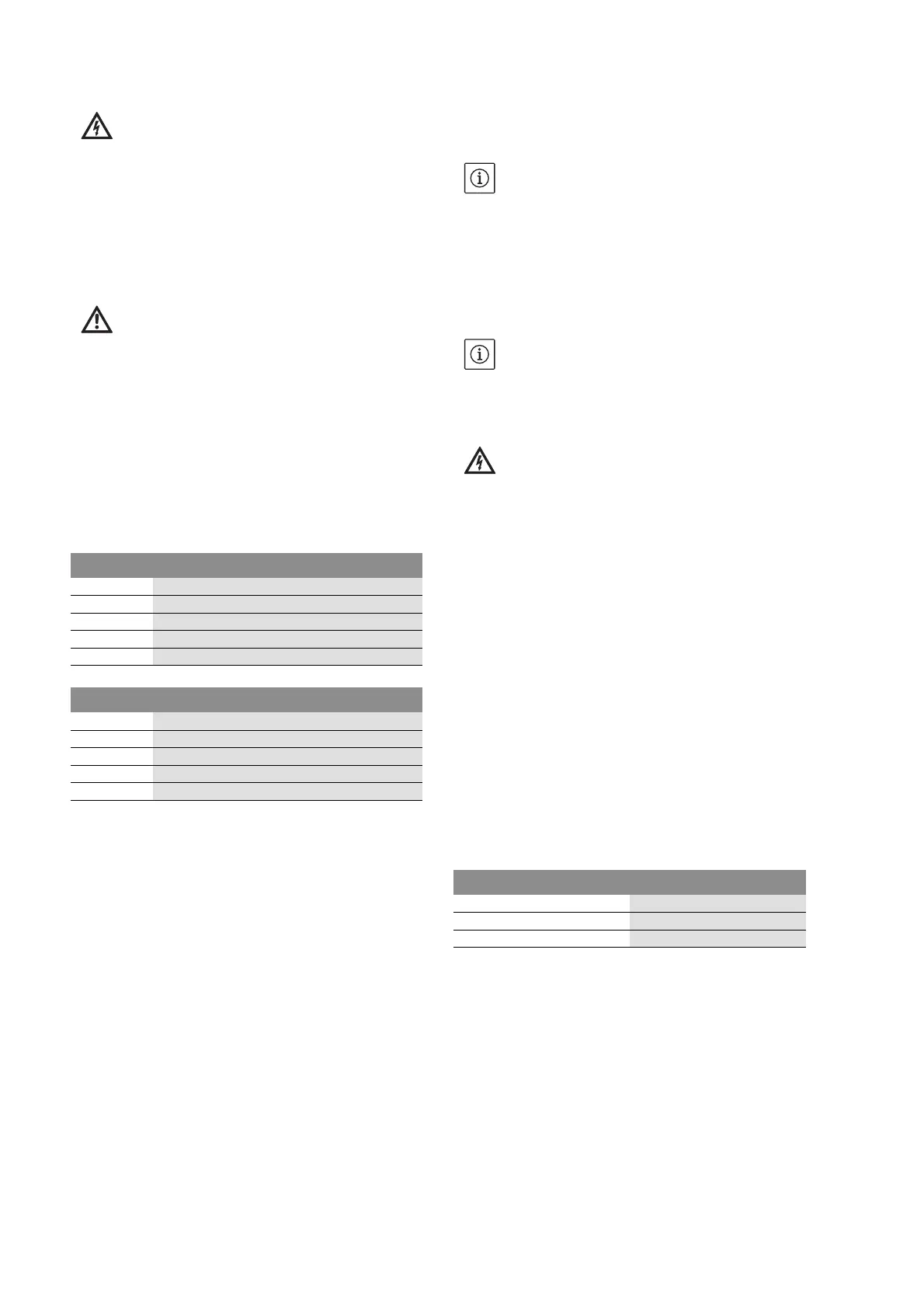

Installation dimension / shaft dimensions

(cf. Fig 2)

The diameter of the pressure pipe (pipe/hose con-

nection) should not be smaller than the pressure

connection of the pipe because of the increased

risk of clogging and greater pressure losses. To

avoid pressure losses, it is recommended that the

pipe connection one number higher is selected.

Stationary wet sump installation

In the case of a stationary wet sump installation of

the pump with a permanent pressure pipe, the

pump must be positioned and secured so that:

• The pressure pipe connection does not support

the weight of the pump.

• The load of the pressure pipe does not act on the

connecting socket.

• The pump is installed stress-free.

To protect against any backflow from the public

drainage pipe, the pressure pipe must be taken in

an arc over the locally established backflow level

(usually street level). A non-return valve does not

represent a guaranteed backflow seal.

• The attached non-return valve should be installed

if the pump is installed permanently.

• Seal the pipe connections to the pressure port

with Teflon tape.

NOTE: Permanent leakage in this area can lead to

destruction of the non-return valve and of the

screwed connection.

Transportable wet sump installation

In the case of a transportable wet sump installa-

tion with hose connection, the pump must be

secured in the shaft to prevent it from falling over

and wandering (e.g. secure chain / rope with slight

pre-tension).

NOTE: When used in a sump without a firm base,

the pump must be put on a sufficiently large plate

or hung from a rope or a chain in a suitable posi-

tion.

7.2 Electrical connection

Danger! Risk of fatal injury!

If the electrical connection is not made properly,

there is a risk of fatal injury from an electric

shock.

Only allow the electrical connection to be made

by an electrician approved by the local electric-

ity supplier and in accordance with the local reg-

ulations in force.

• The type of mains connection current and voltage

must correspond to the details on the name plate

• Fuse in the power supply: 10 A, slow,

• Earth the installation according to the regulations.

• The installation of a leakage current protection

switch to be provided on site for a trip current of

30 mA is recommended (caution when installing

outside).

• The pump is ready to connect.

To connect the pump to the switchgear, the

shock-proof plug is disconnected and the con-

necting cable is then connected as follows (see

Installation and operating instructions for the

switchgear):

3-wire connection cable: 3x1.0

mm

²

Socket and switchgear must be installed in a dry

room and protected against flooding.

Pump H

min

B

min

h ± 8 h1 ± 8 h2 ± 8

Drain [mm]

TS 32/9 400 400 x 400 330 130 14

TSW 32/8

400 400 x 400 340 140 24

TS 32/12

400 400 x 400 350 130 14

TSW 32/11 400 400 x 400 360 140 24

Pump a b c d

Drain

TS 32/9 246 280 320 161

TSW 32/8

266 300 340 161

TS 32/12

270 300 340 171

TSW 32/11

290 320 360 171

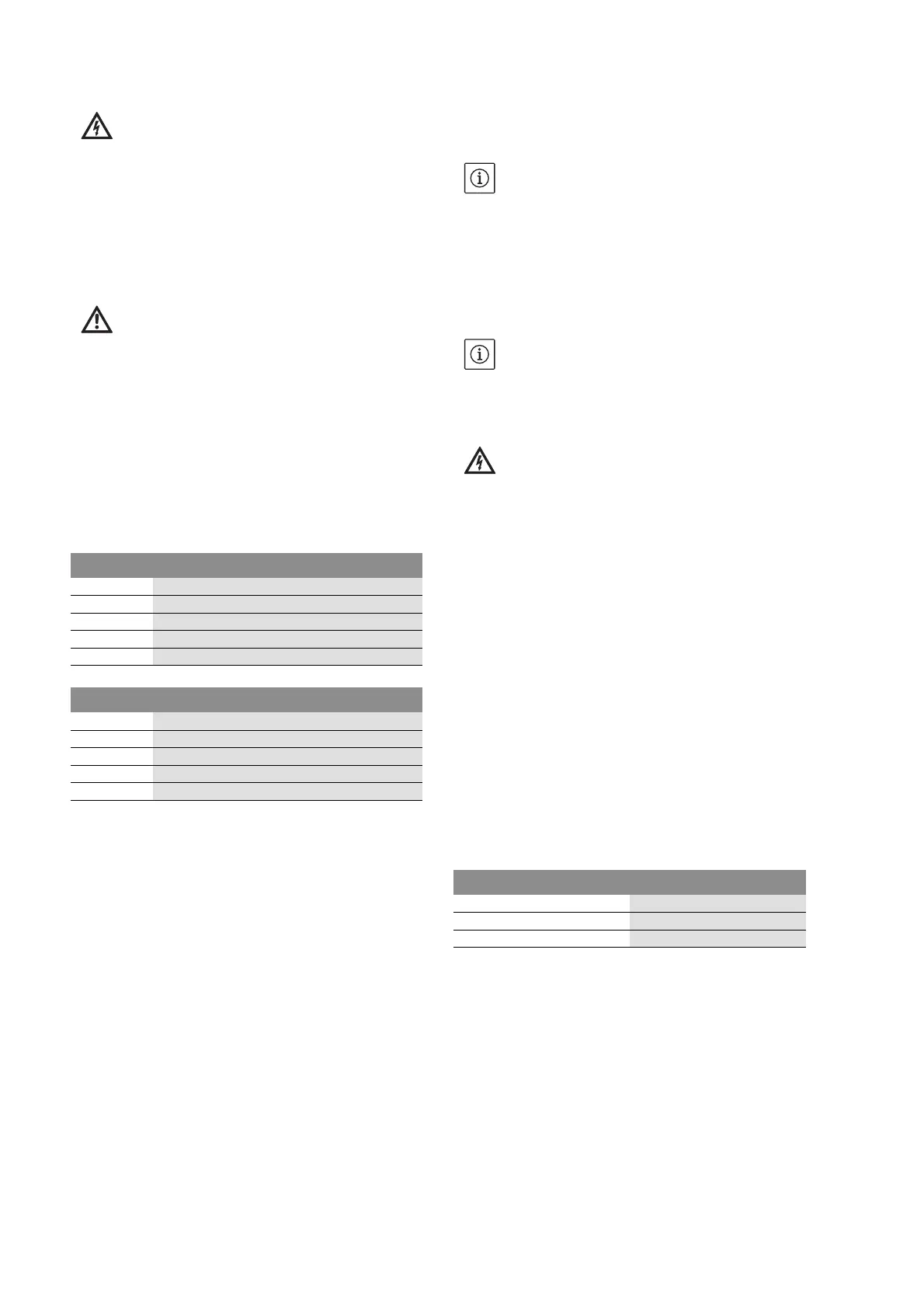

Conductor Terminal

brown L1

blue

N

green/yellow PE

Loading...

Loading...