English

10 WILO SE 03/2015

WARNING! Risk of injuries to personnel and property damage!

The flange connection can be damaged and develop leaks if the pump is not installed

correctly. There is a risk of injury and damage to property due to hot fluid escaping.

• Never connect two combination flanges to each other!

• Pumps with combination flanges are not suitable for PN16 operating pressures.

• The use of securing elements (e.g. spring rings) can result in leaks at the flange con-

nection. They are therefore not permitted. The washers supplied (fig. 3b, item 1) must

be inserted between screw/nut heads and the combination flange.

• The permissible tightening torques listed in the table below must not be exceeded,

even if screws of higher strength (≥ 4.6) are used, since otherwise splintering can

occur at the edges of the long holes. This causes the screws to lose their pretension

and the flange connection can become leaky.

• Use screws of sufficient length. The screw thread must protrude at least one thread

turn beyond the nut (fig. 3b, item 2).

fig.

• Install appropriate flat gaskets between pump and counter flanges.

• Tighten the flange bolts crosswise in two steps to the prescribed tightening torque

(see Table 7.1.2).

• Step 1: 0.5 x permissible tightening torque

• Step 2: 1.0 x permissible tightening torque

• Check the flange connections for leaks.

7.1.3 Pump insulation in heating, refrigeration and air-conditioning systems

WARNING! Risk of burns!

The entire pump can become very hot. When retrofitting the insulation during normal

operation there is a risk of burns.

• Thermal insulation shells (optional accessories) are only permissible in heating applica-

tions with fluid temperatures starting from +20°C, since these thermal insulation shells

are not diffusion-proof when enclosing the pump housing. Install a thermal insulation

shell before commissioning the pump.

• For refrigeration system and air-conditioner applications, use commercially available dif-

fusion-proof insulation materials.

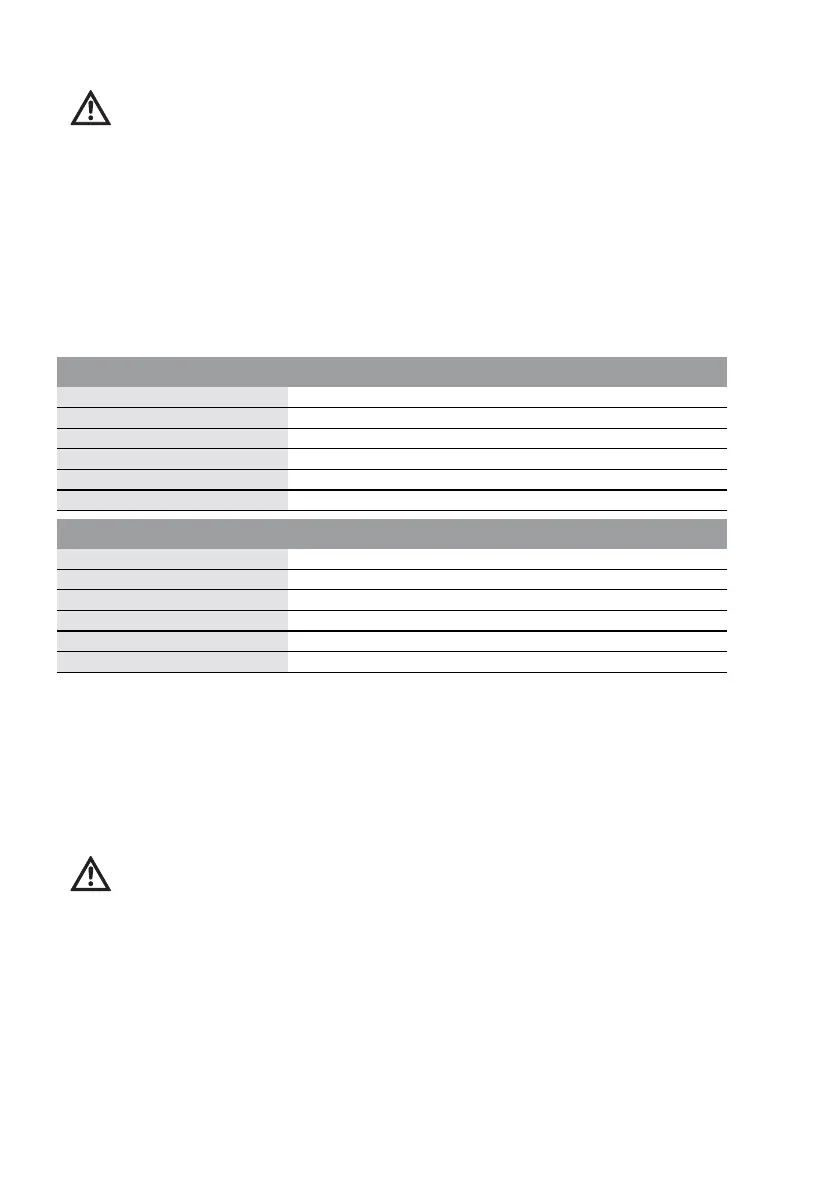

DN 32, 40, 50, 65 Nominal pressure PN6 Nominal pressure PN10/16

Screw diameter M12 M16

Strength class 4.6 or higher 4.6 or higher

Permitted tightening torque 40 Nm 95 Nm

Min. screw length for

• DN 32/DN 40 55 mm 60 mm

• DN 50/DN 65 60 mm 65 mm

DN 80, 100 Nominal pressure PN6 Nominal pressure PN10/16

Screw diameter M16 M16

Strength class 4.6 or higher 4.6 or higher

Permitted tightening torque 95 Nm 95 Nm

Min. screw length for

• DN 80 65 mm 65 mm

• DN 100 70 mm 70 mm

Loading...

Loading...