10

TORCH WIZARD INSTALLATION & OPERATION MANUAL

4.0 MAINTENANCE OF CLEANING STATION & WIRE CUTTER

The Torch Wizard® is for the most part, a low maintenance peripheral. However, maintenance of this unit should still be

added to your preventive maintenance schedule. The following should be checked at regular intervals:

Visually inspect unit for damage, especially

mechanically stressed components

Clean the filter

Check that the air lines are free of leaks

Ensure the lubricator has lubricant and fill if necessary

Check blade for chips or cracks, replace if necessary

Check for lose parts

Ensure the proper depth of blade in the nozzle

Ensure the blade is not making contact with the diuser

Ensure all covers are in place before operating

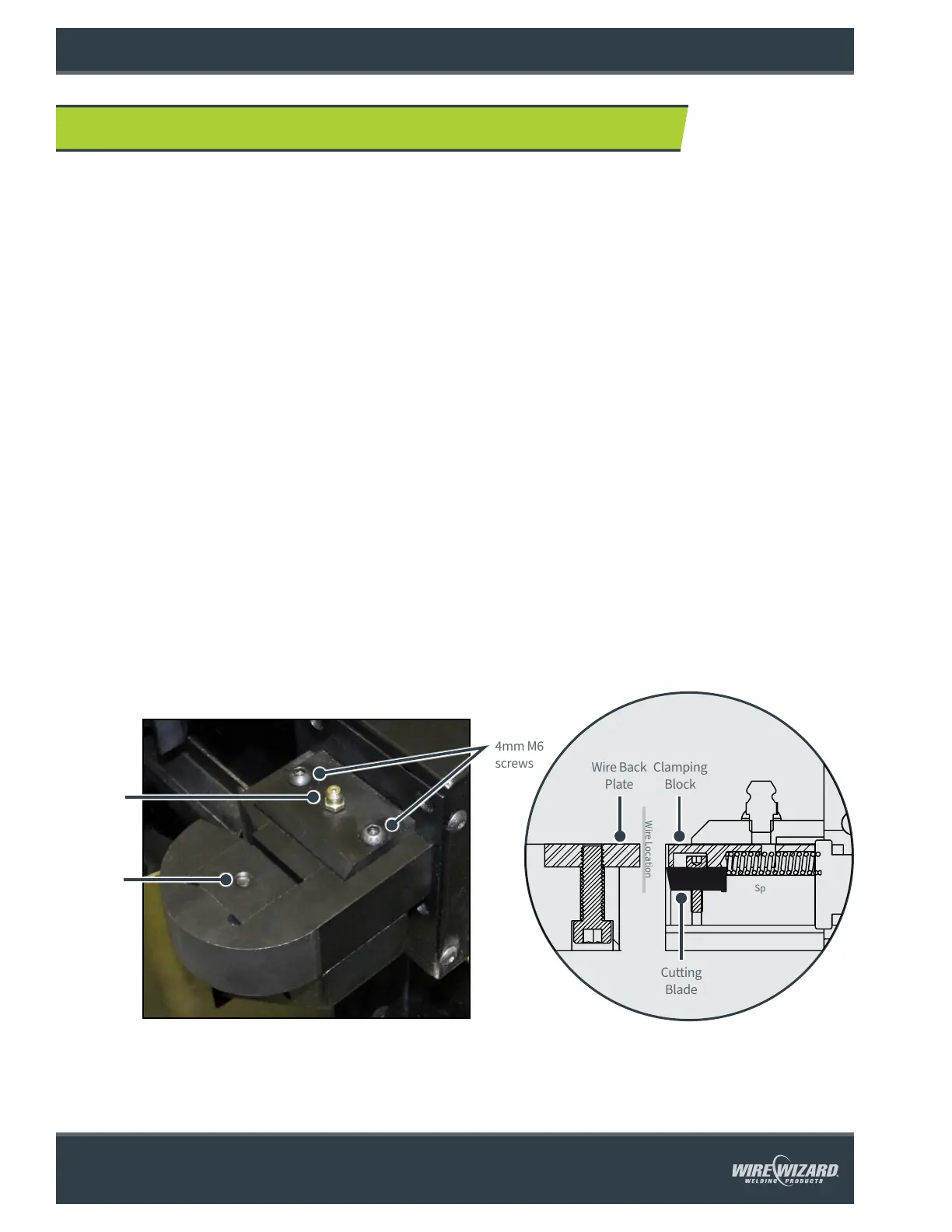

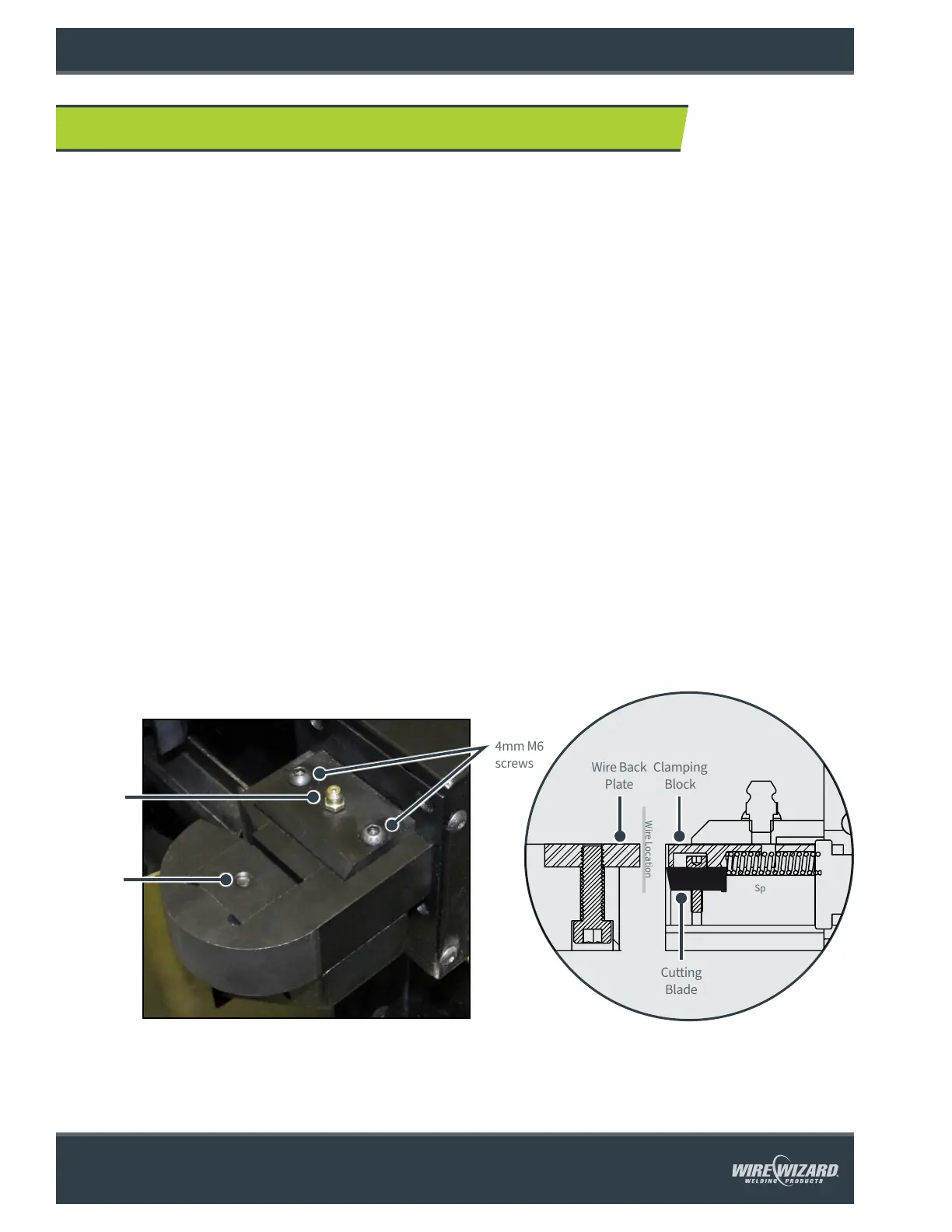

Wire Cutter Maintenance (if applicable)

The wire cutter blade and back plate should be checked occasionally for wear. Replace blade (pt. #NCS-WCS-08) if worn.

If the back plate is worn, it may be removed and flipped around to the other end. To disassemble and install a new blade,

remove the two screws on the top of the cutter with a 4 mm wrench. Remove the slide piece that rests on top of the blade

and then remove the screw holding the blade with a 2.5 mm wrench. Install the new blade with the angled side facing up

as shown in Fig. 9. Reassemble unit.

The wire back plate may be flipped by removing the screw on the bottom of the cutter with a 5 mm wrench. Replacement

blades and other wire cutter components are available from ELCo Enterprises.

The wire cutter should also be greased approximately once every 10,000 cycles with multi-purpose grease.

4mm M6

screws

Grease Zirc

5 mm M6

screw

Wire Back

Plate

Cutting

Blade

Figure 8: Wire Cutter, Exterior View Figure 9: Wire Cutter, Interior View

Wire Location

Spring

Clamping

Block

Wire Cutter Replacement Parts:

Cutting Blade Pt. #NCS-WCS-19

Wire Back Plate Pt. #NCS-WCS-16

Clamping Block Pt. #NCS-WCS-07

Replacement Spring Pt. #C0240-045-1000-S

Loading...

Loading...