Pre-Installation

6 720 811 922 (2014/07) 13

3.6 BOILER LOCATION AND CLEARANCES

3.6.1 INSTALLATION

This boiler is only suitable for installing internally within a property at a

suitable location onto a fixed, rigid surface at least the same size as the

boiler and capable of supporting the boiler weight.

3.6.2 INSTALLATION AND SERVICING CLEARANCES -

UNVENTILATED COMPARTMENTS

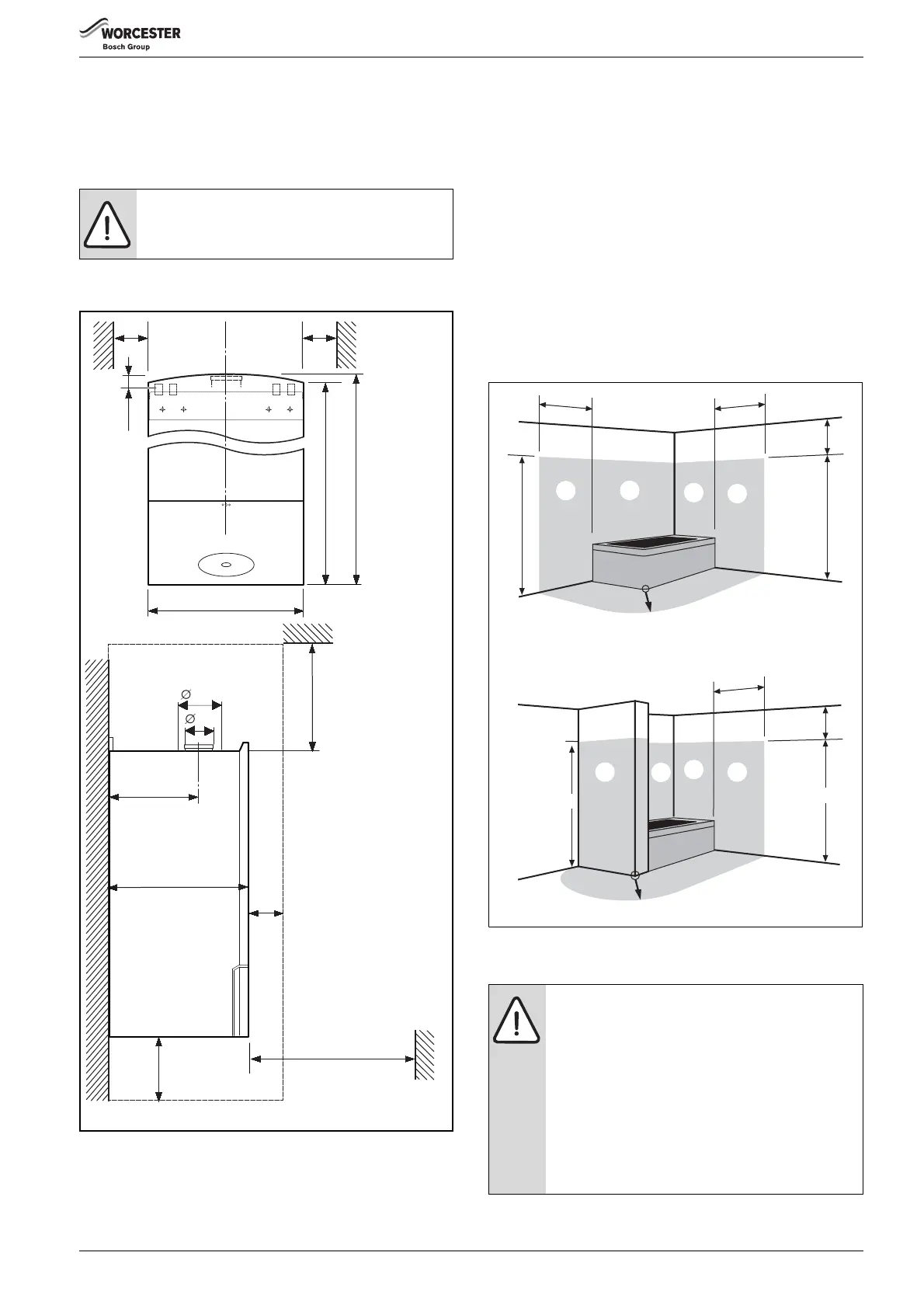

Fig. 15 Compartment clearances

[*] Minimum clearance to removable door

[**] Minimum clearance required for servicing

[***] Minimum clearance required to remove expansion vessel with

boiler mounted with left or right flue exit

3.6.3 COMPARTMENTS

Follow the requirements of BS6798 and BS5440 Part 2 and note:

• Minimum clearances must be maintained.

• An access door is required to install, service and maintain the boiler

and any ancillary equipment.

• If fitting the boiler into an airing cupboard use a non-combustible

material to separate the boiler from the airing space.

The material can be perforated up to a maximum hole size of 13mm.

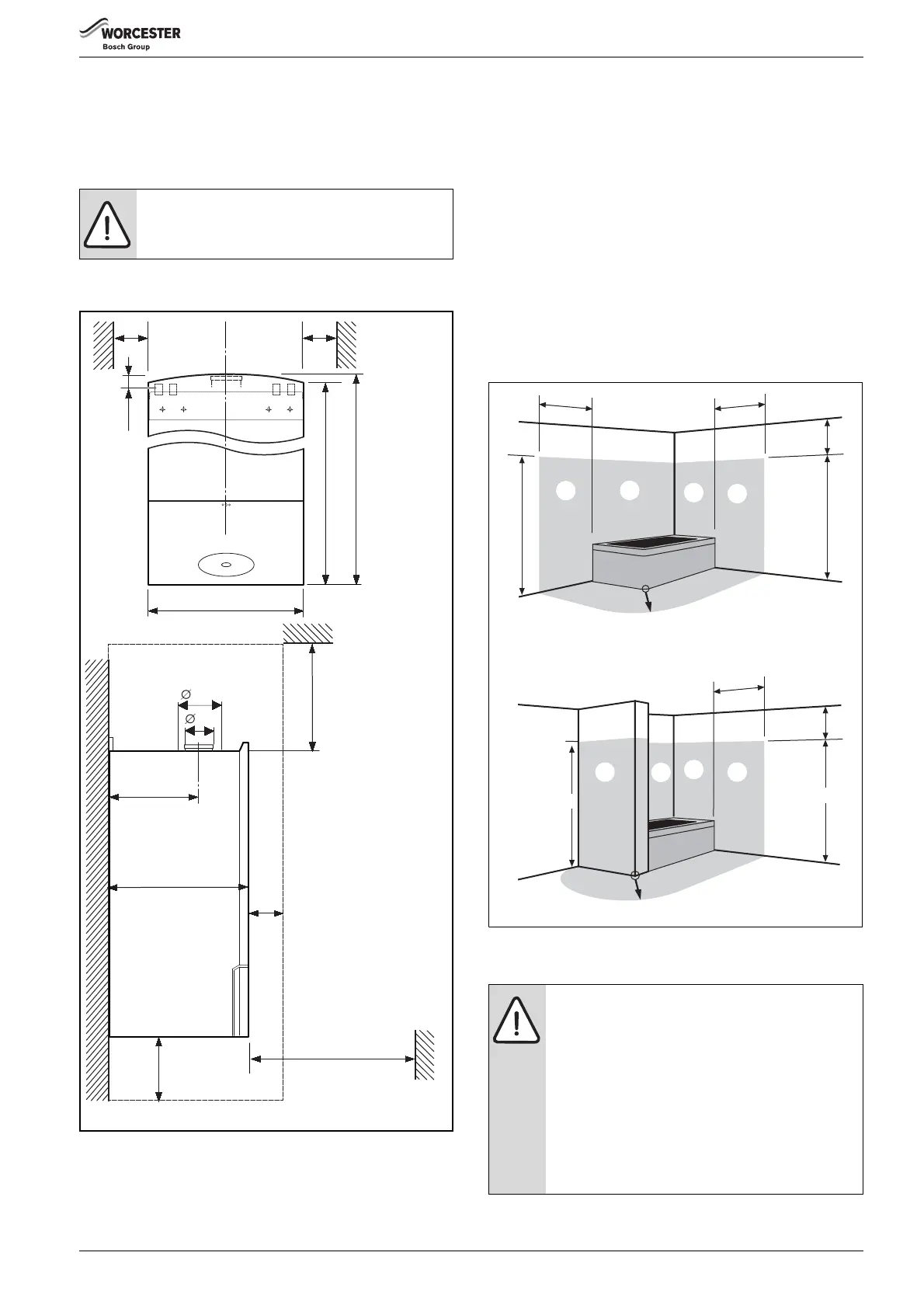

3.6.4 BATHROOMS

A boiler fitted with a mechanical timer or RF mechanical timer (receiver)

or FW100 controller may only be installed outside the shaded area.

A boiler with any other timer fitted (or blanking panel) can also be

installed in zone 2.

Additional RCD (Residual Current Device) protection may be required.

Consult the latest version of BS7671 (IEE wiring regulations).

Fig. 16 Bathroom installations

3.7 FLUE OPTIONS

NOTICE:

No surface protection is required against heat transfer

from the boiler

min.

10

min.

10

400

15

840

850

6720800945-02.1Wo

370

200**

170 (60/100 flue)**

210 (80/125 flue)**

400 ***

600**

20*

218

125

80

CAUTION: Non accessible flue systems:

▶ Where a flue system is not going to be accessible,

provision must be made for service and inspection.

▶ Voids containing concealed flues must have at least

one inspection hatch no less than 300mm square.

▶ Flue joints within the void must not be more than 1.5

metres from the edge of the inspection hatch.

▶ Inspection hatches should be located at changes of

direction.

▶ If this is not possible, bends should be viewable from

both directions.

600mm radius

600 mm

600 mm

750 mm

2250 mm

2250 mm

600 mm

2250 mm

600mm radius

750 mm

2250mm

6720643895-10.1Wo

1

1

1

1

2 2

2

2

Loading...

Loading...