Service

6 720 811 922 (2014/07)38

SERVICE FUNCTION B.F: START DELAY

This service function allows you to set the time in seconds before the

appliance starts DHW heating. Set the start delay in accordance with

system conditions.

The start delay can be set between 0 - 50 seconds.

Standard setting is 00 (disabled).

8SERVICE

8.1 CHECKING THE GAS SUPPLY PRESSURE

▶ Switch off the appliance and turn off the gas tap.

▶ Undo the plug on the test port for gas supply pressure and connect a

pressure gauge.

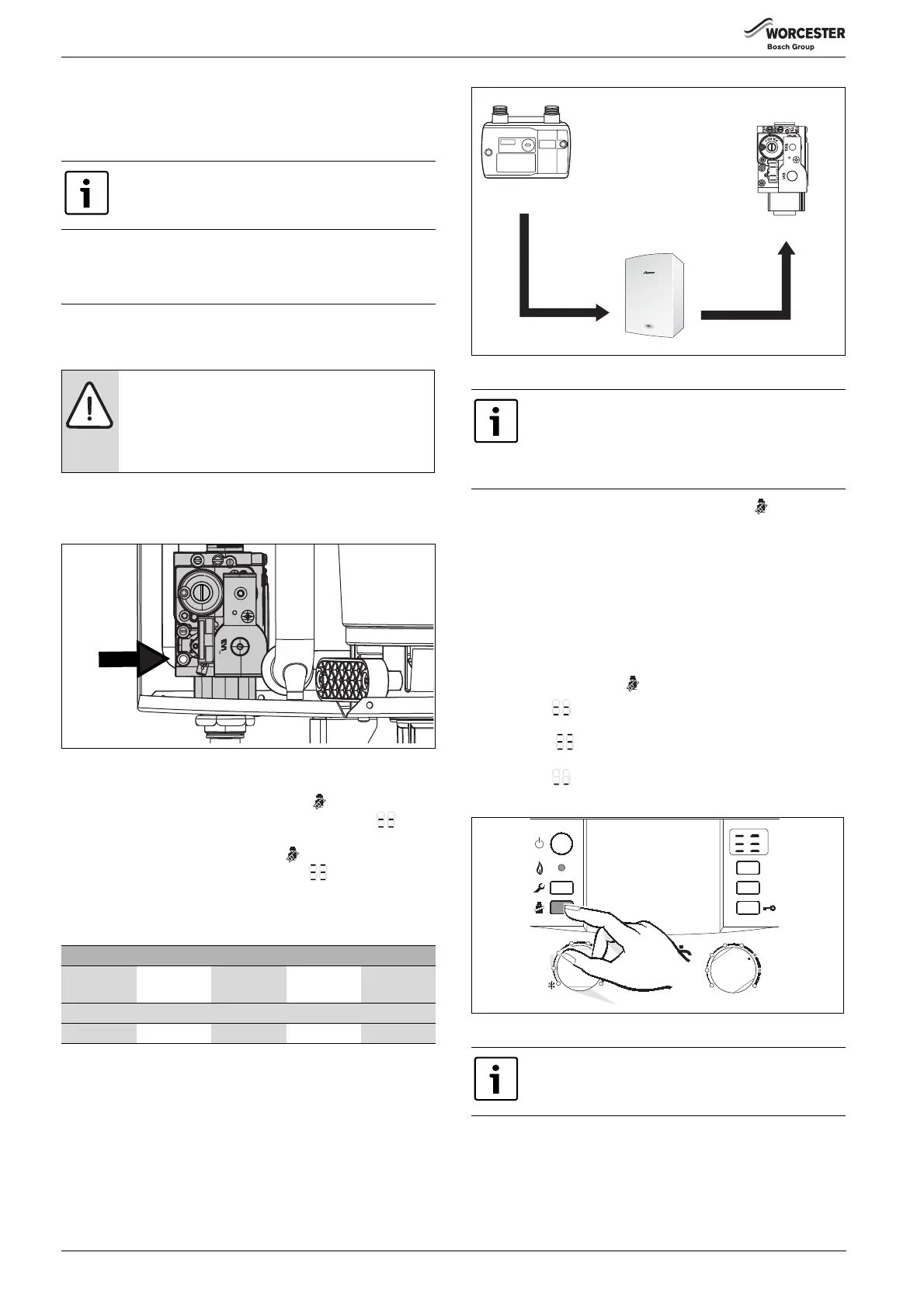

Fig. 59

▶ Turn on the gas tap and switch on the appliance.

▶ Hold down the Central Heating boost button until it illuminates.

The display shows the flow temperature alternating with =

maximum heating output setting.

▶ Press the Central Heating boost button again and the display will

show the flow temperature alternating with = maximum rated

output.

▶ Check that the gas working pressures in the system conform to the

figures shown below:

Fig. 60 Natural gas pressure

▶ Repeatedly press the Central Heating boost button until the light

extinguishes.

The display will show the Central Heating flow temperature.

▶ Switch off the appliance, turn the gas tap to OFF, remove the

pressure gauge and refit the plug.

▶ Refit the outer casing.

8.2 CHECK FLUE INTEGRITY

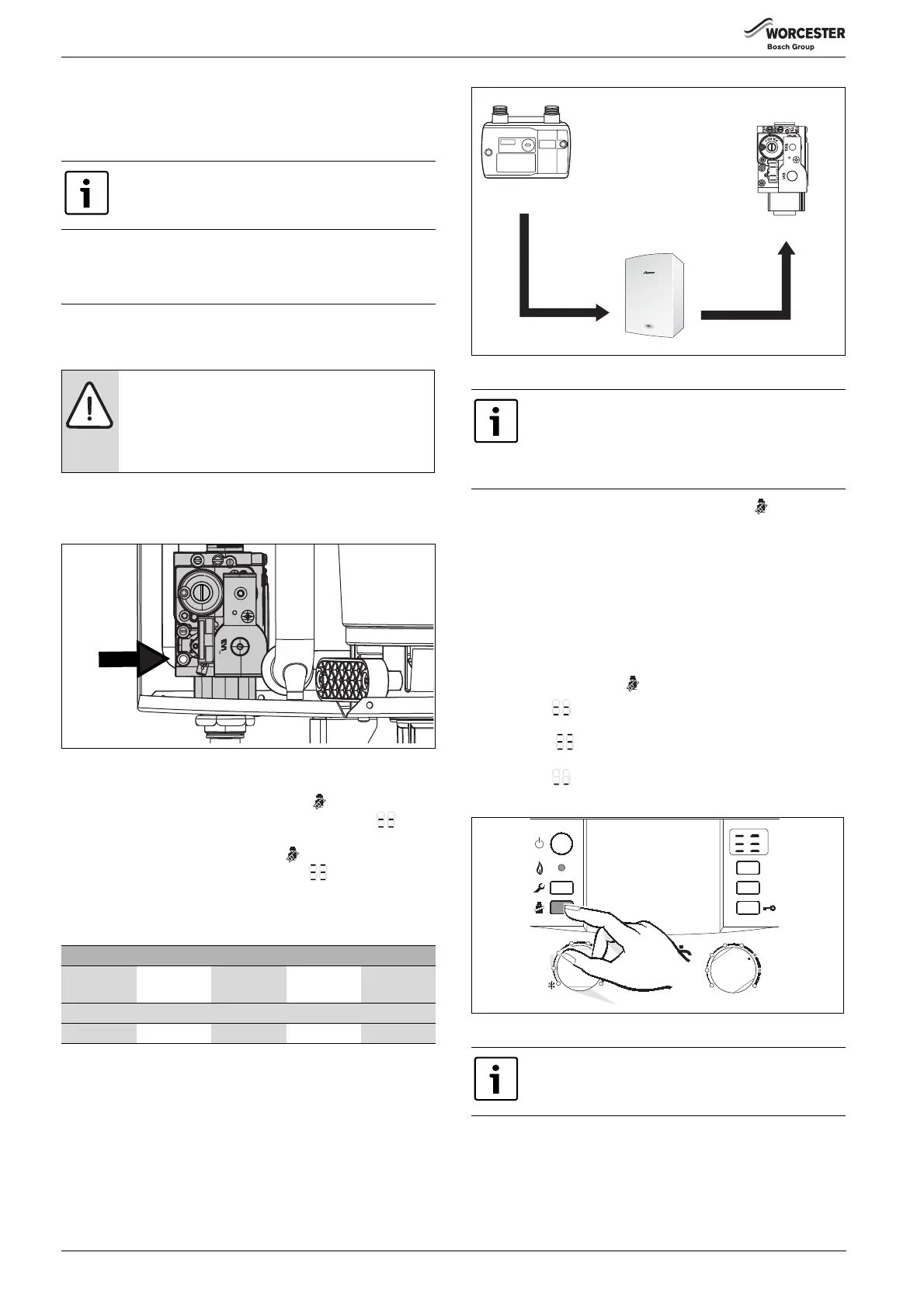

Central Heating boost button

The following appliance output can be selected by holding down the

Central Heating boost button until it illuminates:

• 1st press = = maximum heating output setting

• 2nd press = = maximum rated output

• 3rd press = = minimum rated output

• 4th press = EXIT from Central Heating boost.

Fig. 61

8.3 CHECKING FLUE SYSTEM FOR TIGHTNESS

Measure the CO

2

levels in combustion air.

Use an annular-gap flue gas probe for this test.

If a start delay is set, the demand signal is no longer

possible page 32.

NOTICE:

▶ Ensure that the gas pressure is satisfactory with all

other gas appliances working.

▶ Do not continue with the other checks if the correct

gas pressure can not be achieved.

Allowed mbar pressure drop

meter/

regulator

across

pipework

boiler inlet across

boiler

gas control

valve

Natural gas

19 - 23 1 18 - 22 1.5 16.5 - 20.5

Table 24

The appliance must not be operated if the pressure is

above or below these figures. Determine the cause and

correct the fault. If that is not possible, securely seal off

the gas supply to the appliance and contact the gas

supply utility.

You have 15 minutes in which to measure the levels.

After that, the appliance reverts from “boost” mode to

standard mode.

Meter

Boiler inlet

Gas Control

valve

19 - 23 mbar

18 - 22 mbar

16.5 - 20.5 mbar

1 mbar

drop

1.5 mbar

drop

Natural Gas

6720644744-44.1Wo

max

1

2

3 4

5

6

eco

reset

6 720 615 065-18.1O

max

1

2

3

4

e

6

min

Loading...

Loading...