5

* NOTE: For use on conventional flue only.

** NOTE: The flue gas temperature is measured in the gas sampling hole on the flue outlet plate. The probe should be inserted to a depth of 50mm and angled towards the flue outlet.

The temperature measured is not an absolute flue gas temperature and is for general guidance purposes only!

NOTE: The pump pressure given is for general guidance only as variations in nozzle output can be up to ± 15%. It is, therefore, essential that the air is adjusted to give the correct CO

2

value.

NOTE: The nozzle type used on 28 Sec. Kerosene outputs are nozzles calibrated specifically for use with 28 Sec. Kerosene which gives less variation in nozzle output than the standard

35 Sec. Gas Oil nozzles. However, if a 28 Sec. Kerosene nozzle is not available at servicing or commissioning it is appropriate to install a 35 Sec. Gas Oil nozzle providing the output, spray

angle and pattern of the nozzle is the same as the 28 Sec. Kerosene nozzle (e.g. 0.75 80°EH may be replaced with a 0.75 80°H).

~NOTE: At 70kW the air guide should be removed (See Fig. 24)

28 Sec. Kerosene 0.85 80°EH 110 2.36 2.99 225 11.0-11.5 10 28.5 97,000 26 89,000

28 Sec. Kerosene 0.85 80°EH 130 2.66 3.37 240 11.0-11.5 15 32 109,000 29 99,000

28 Sec. Kerosene 1.00 80°EH 130 2.95 3.74 245 11.5-12.0 20 35.5 121,000 32 109,000

NOMINAL BOILER RATING AT NORMAL OPERATING TEMPERATURE

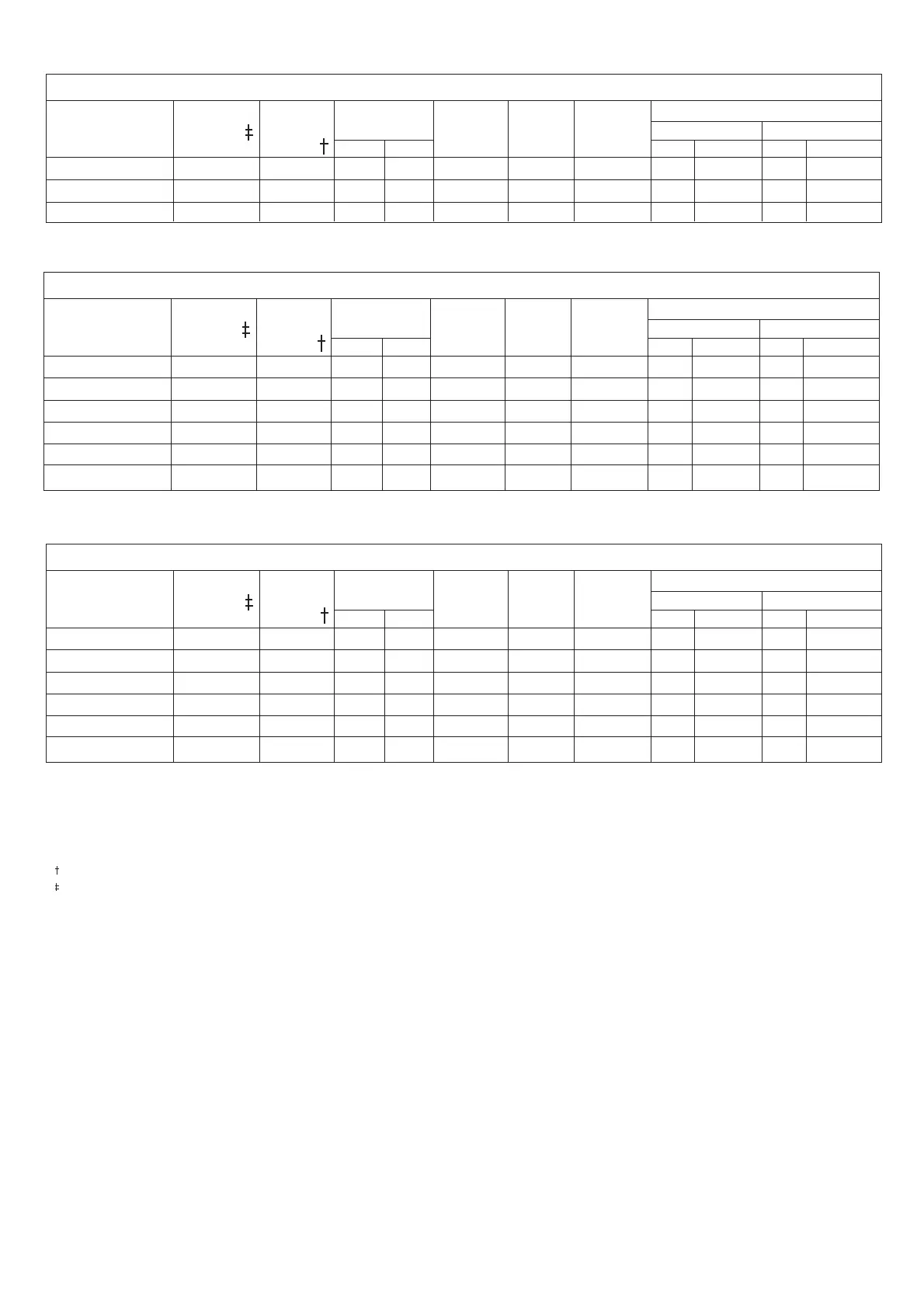

26/32 Table 7. Electro Oil Sterling 40 Burner (See Fig. 23) RS Balanced Flue Appliance

Fuel Nozzle

Pump

Pressure

(p.s.i.)

Fuel Flow

Rate

Flue Gas

Temp.

(°C)**

%CO

2

Approx.

Air

Setting

Appliance

Input

kW Btu/hr kW Btu/hr

Output

Kg/h l/h

28 Sec. Kerosene* 1.00 60°ES 130 2.90 3.67 185 11.5-12.0 7.50 35 119,000 32 109,000

28 Sec. Kerosene* 1.25 60°S 130 3.78 4.78 200 12.0-12.5 14.25 45 155,000 41 140,000

28 Sec. Kerosene* 1.65 60°S 115 4.64 5.87 230 12.0-12.5 23.50 56 191,000 50 171,000

35 Sec. Gas Oil* 0.65 80°S 185 2.95 3.47 190 11.0-11.5 8.75 35 119,000 32 109,000

35 Sec. Gas Oil* 0.85 60°S 200 3.83 4.51 205 11.0-11.5 17.00 45 155,000 41 140,000

35 Sec. Gas Oil* 1.10 60°S 185 4.71 5.54 235 12.0-12.5 25.00 56 191,000 50 171,000

NOMINAL BOILER RATING AT NORMAL OPERATING TEMPERATURE

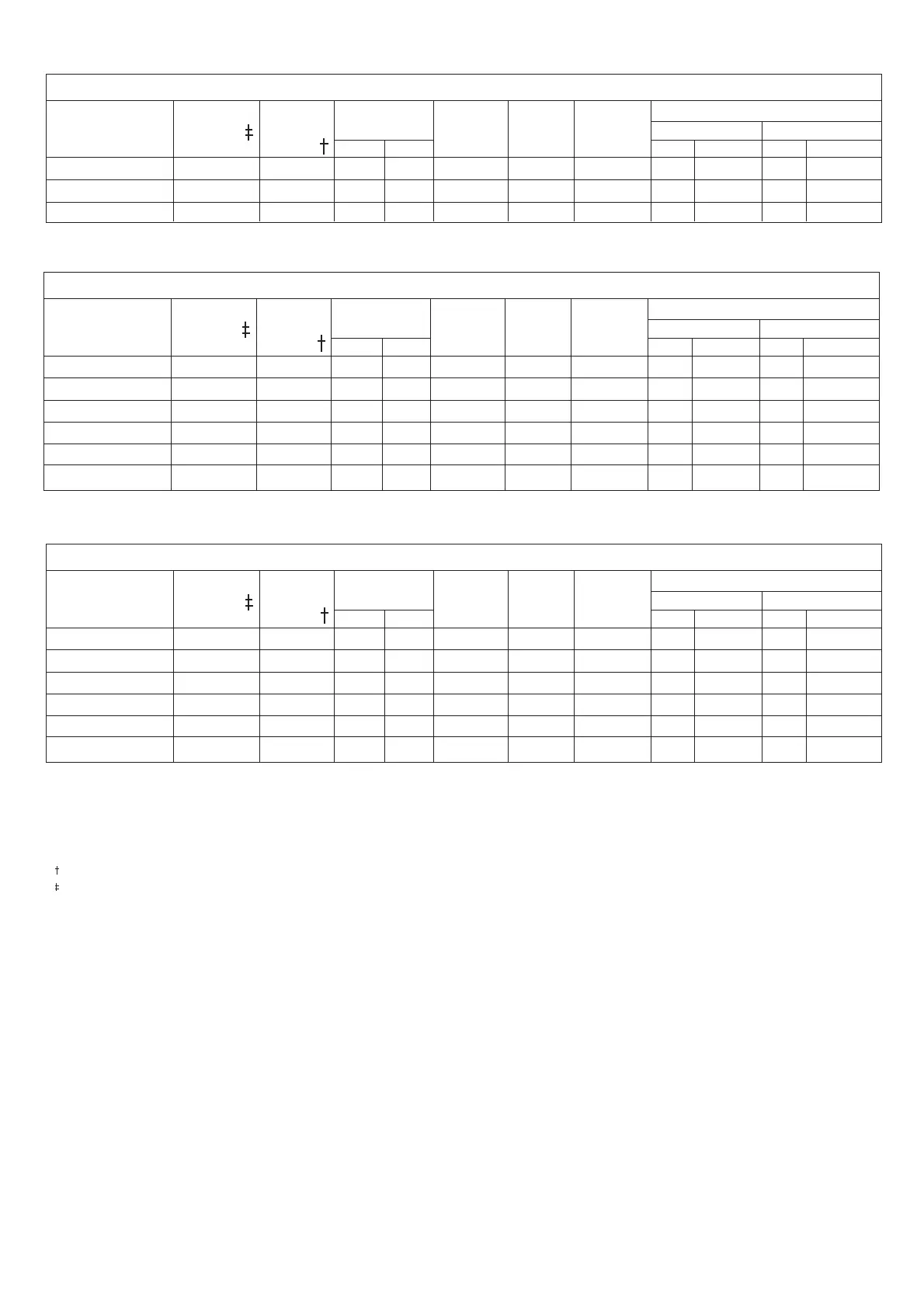

32/50 Table 8. Electro Oil Sterling 50 Burner (See Fig. 23) Conventional Flue Appliance (CF)

Fuel Nozzle

Pump

Pressure

(p.s.i.)

Fuel Flow

Rate

Flue Gas

Temp.

(°C)**

%CO

2

Approx.

Air

Setting

Appliance

Input

kW Btu/hr kW Btu/hr

Output

Kg/h l/h

28 Sec. Kerosene* 1.35 60°S 165 4.62 5.85 205 11.5-12.0 3 55.5 190,000 50 171,000

28 Sec. Kerosene* 1.75 60°S 155 5.55 7.03 225 12.0-12.5 4 67 229,000 60 205,000

~28 Sec. Kerosene* 2.00 60°S 145 6.47 8.19 235 12.0-12.5 4.5 78 268,000 70 239,000

35 Sec. Gas Oil* 1.00 60°S 240 4.69 5.52 205 11.0-11.5 3 55.5 190,000 50 171,000

35 Sec. Gas Oil* 1.35 60°S 180 5.63 6.62 225 12.0-12.5 4 67 229,000 60 205,000

~35 Sec. Gas Oil* 1.75 60°S 160 6.57 7.73 235 12.0-12.5 4.5 78 268,000 70 239,000

NOMINAL BOILER RATING AT NORMAL OPERATING TEMPERATURE

50/70 Table 9. Electro Oil Inter B20B Burner (See Fig. 24) Conventional Flue Appliance (CF)

Fuel Nozzle

Pump

Pressure

(p.s.i.)

Fuel Flow

Rate

Flue Gas

Temp.

(°C)**

%CO

2

Approx.

Air

Setting

Appliance

Input

kW Btu/hr kW Btu/hr

Output

Kg/h l/h

Loading...

Loading...