Installation

6720813174 (2014/09) 7

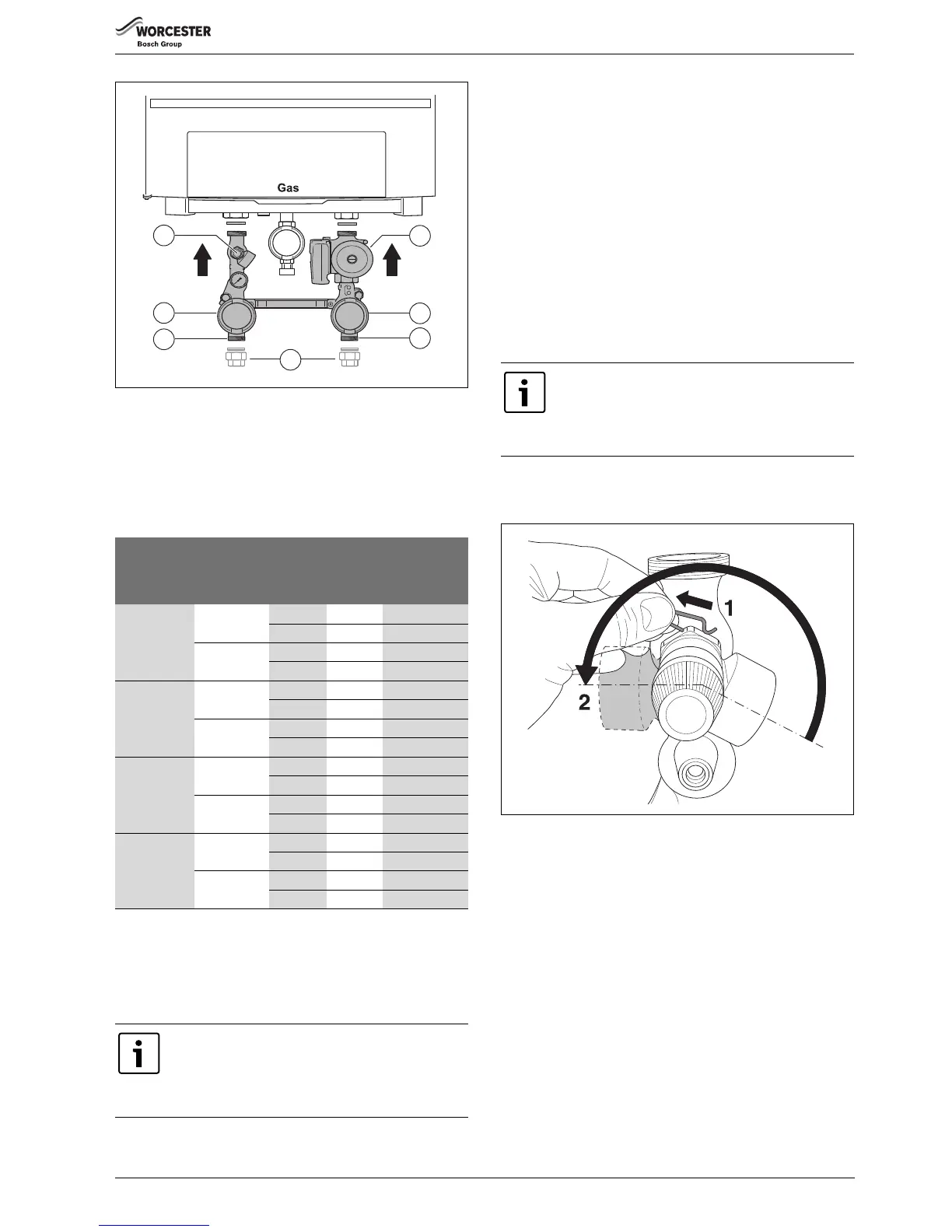

Fig. 9 Installing the isolating valves

[1] Pressure relief valve

[2] Isolating valve, red

[3] Flow connection

[4] Screw fitting 1" female thread (accessory)

[5] Pump

[6] Isolating valve, blue

[7] Return connection

▶ Install a shut-off valve for filter cleaning immediately upstream and

downstream of the dirt filter.

Installing the differential pressure controller

In situations where there is no low less header, installing a by-pass valve

with a differential pressure controller would be required.

If a low less header is present, it may be required -depending on the

situation - to install a differential pressure controller to the secondary

side of the open manifold. This serves to protect the secondary pump

against overheating as a result of insufficient flow.

Installing the drain cock

Since the isolating valve for the return circuit already has an integrated

filling and drain valve, fitting a drain valve is not necessary.

Installing the non-return valve

Since the isolating valve for the return circuit (blue) already has an

integrated non-return valve, fitting a non-return valve in the return circuit

is not necessary.

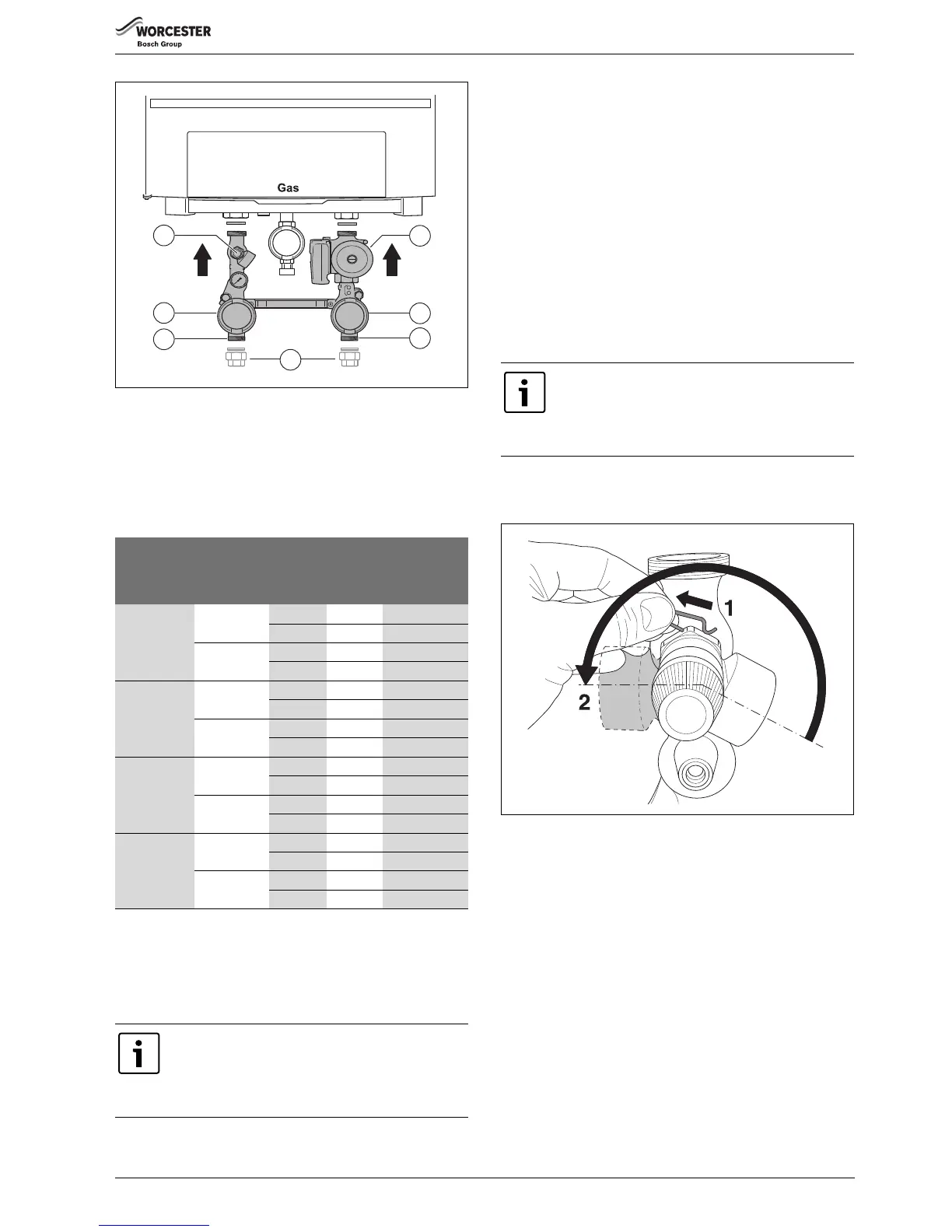

5.5 Rotating the pressure relief valve

▶ Remove the retaining pin from the pressure relief valve body

(step 1).

▶ Rotate the valve body (step 2).

Fig. 10 Removing the retaining pin

boiler pump

non

return

valve

residual

head

[mbar]

with minimum

required

volume flow

[l/h]

GB162-50

UPS 25-80

with

1)

1) Switch required

2,200

without 550 2,200

UPER 25-80

with

1)

2,200

without 550 2,200

GB162-65

UPS 25-80

with

1)

3,000

without 375 3,000

UPER 25-80

with

1)

3,000

without 375 3,000

GB162-80

UPS 25-80

with 153 3,600

without 259 3,600

UPER 25-80

with

1)

3,600

without 219 3,600

GB162-100

UPS 25-80

with

1)

4,300

without

1)

4,300

UPER 25-80

with

1)

4,300

without

1)

4,300

Table 4 Residual head downstream of pump group with a single-boiler

system (

Δ

T = 20 K)

When using plastic pipework in the heating system, e.g.

for underfloor heating, it has to be oxygen diffusion tight.

If this pipework does not comply with the relevant

standards, a heat exchanger must be integrated to

separate the systems.

Loading...

Loading...