FAULT FINDING

& DIAGRAMS

INSTALLATION & SERVICING INSTRUCTIONS

52

FAULT FINDING

8 716 115 219c (03.2010)

NOTE ; This fault finding information is for

guidance only. Worcester Bosch cannot be held

responsible for costs incurred by persons not

deemed to be competent.

The electronic control system for this boiler

incorporates a blue central indicator. This

normally confirms the permanent mains supply,

but, by flashing during a fault, provides a guide

to the cause as listed.

This fault finding system assumes that the

appliance has been operating normally until the

time of failure (i.e. not a first time installation

error).

Preliminary checks:

Preliminary electrical system checks are the

first electrical checks to be carried out during

a fault finding procedure.

On completion of the Service/Fault finding

task which has required the breaking and

remaking of electrical connections, check:

a) EARTH CONTINUITY

b) SHORT CIRCUIT CHECK

c) POLARITY

d) RESISTANCE TO EARTH.

FAULT FINDING

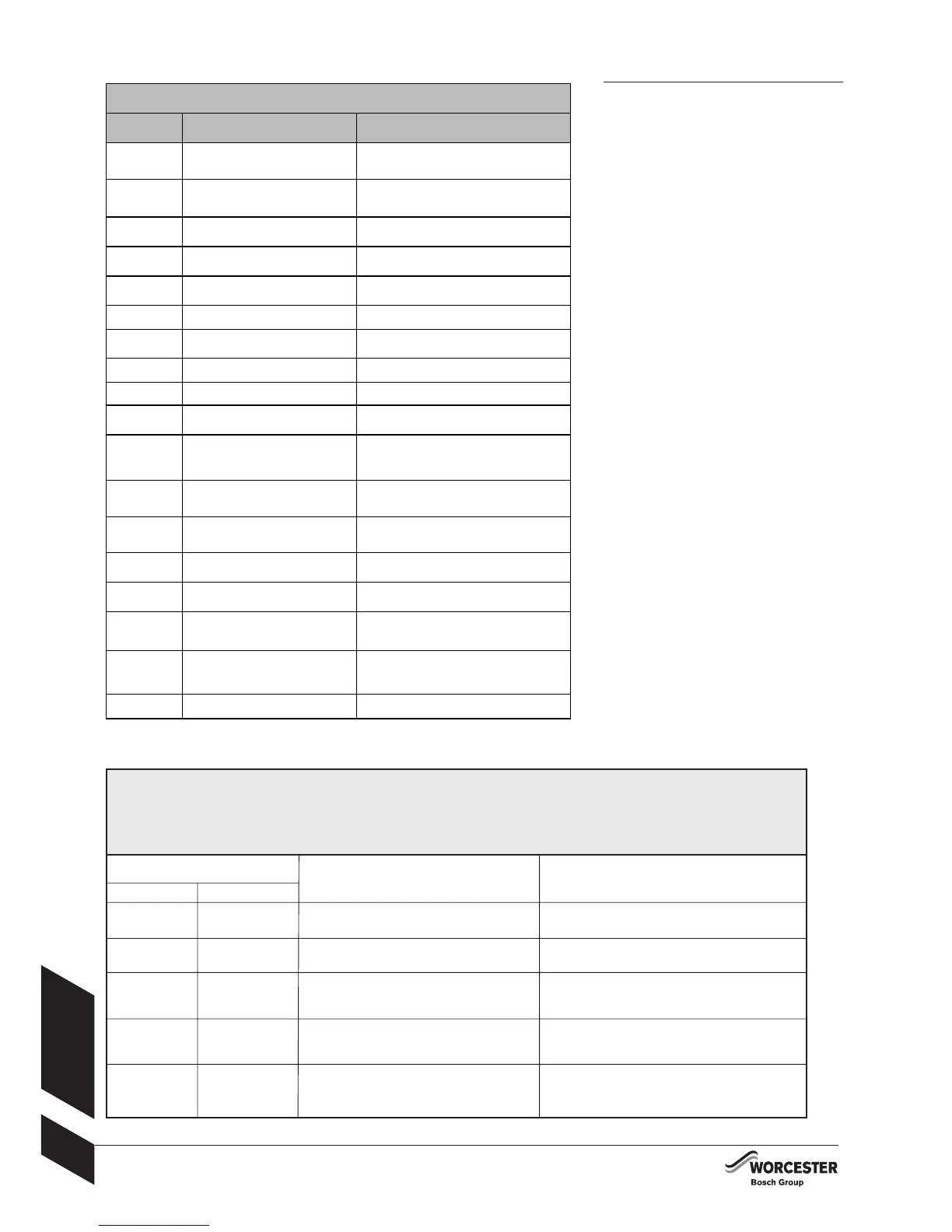

CONDENSATE PUMP - OPERATING LAMPS AND FAULT CONDITIONS

Ready for operation = Steady green light

Fault = Red light

Pump running = Flashing green light

Operating lamps Cause Solution

Green Red

Off Off Mains plug not plugged in Insert plug

Power failure Check mains and fuse

Flashing Flashing Dry-run Pump restarts automatically

(poss. air in pump) after one minute

On Flashing Pump blocked Visual inspection of the pump inlet

in the tank and removal or

rinsing out of dirt/foreign bodies

On On Level exceeds alarm level Pressure hose / non-return valve

blocked (clean or remove kink

if applicable)

Off Flashing Pump blocked and Visual inspection of the pump inlet

alarm level exceeded in the tank and removal or

rinsing out of dirt/foreign bodies

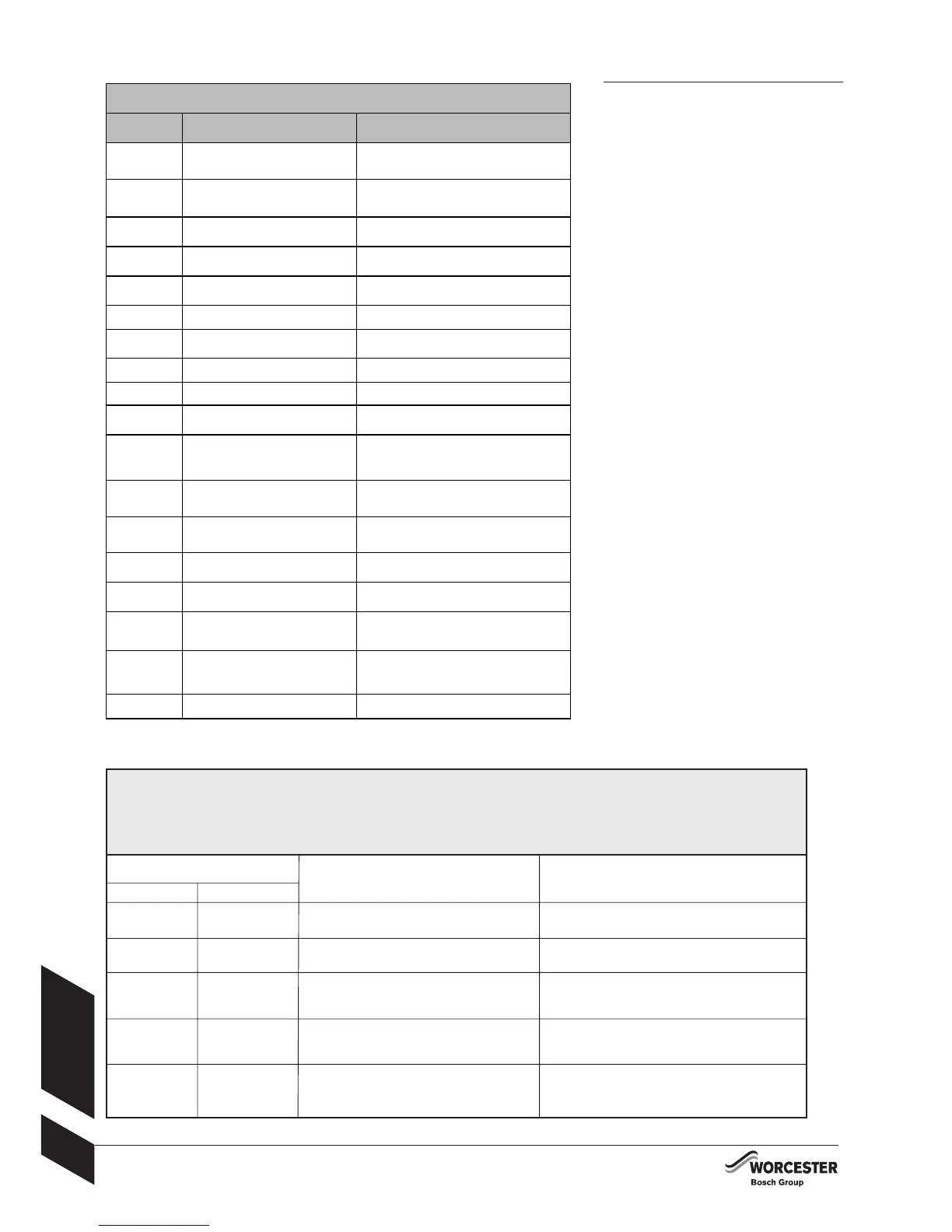

BOILER - FAULTS AND CONDITIONS

Display code: Fault description Check, repair/replace as necessary

A5 Tank NTC defect Check tank NTC sensor and leads,

measure resistance across NTC

(33.5kΩ- 500Ω)

A7 DHW NTC defect Check DHW NTC sensor and leads,

measure resistance across NTC

(33.5kΩ- 500Ω)

A8 EMS communication error Check all electrical connections,

replace control board.

b1 Code plug not detected Insert code plug correctly, test and

replace as necessary.

b2, b3, b4, b5,

b6

Data error Replace control board.

b7 Burner control error Replace control board.

C6 Fan defect Check fan, lead, and connector,

replace as necessary.

D3 External temp limiter Connect terminals 8 & 9 on ST8.

D5 Condensate overflow See condensate pump table.

D6 Internal heat bank overflow Check system pressure, tank, over heat

thermostat, and pump operation

EA Flame not detected Check gas is present, ignition electrodes

and harness, flame sense electrode and

harness, and operation of gas valve.

Replace as necessary.

E2 Primary NTC defect Check primary NTC sensor and leads,

resistance across NTC should be between

36k to 1kΩ

E9 OH stat tripped Check system pressure, over heat thermo-

stat, and pump operation.

Replace as necessary

F0 Internal error Check all electrical connections, replace

board as necessary.

F1 ROM error check Check all electrical connections, replace

board as necessary.

F7 Flame detected after appliance

shut off

Check flame sense electrode and harness,

and control board for signs of water

damage. Replace a s necessary

FA Flame detected after gas shut off Check flame sense electrode and harness,

and control board for signs of water

damage. Check gas valve operation.

Replace a s necessary

Fd Reset button pressed Press reset button again

Loading...

Loading...