7 SERVICE AND MAINTENANCE

7-1

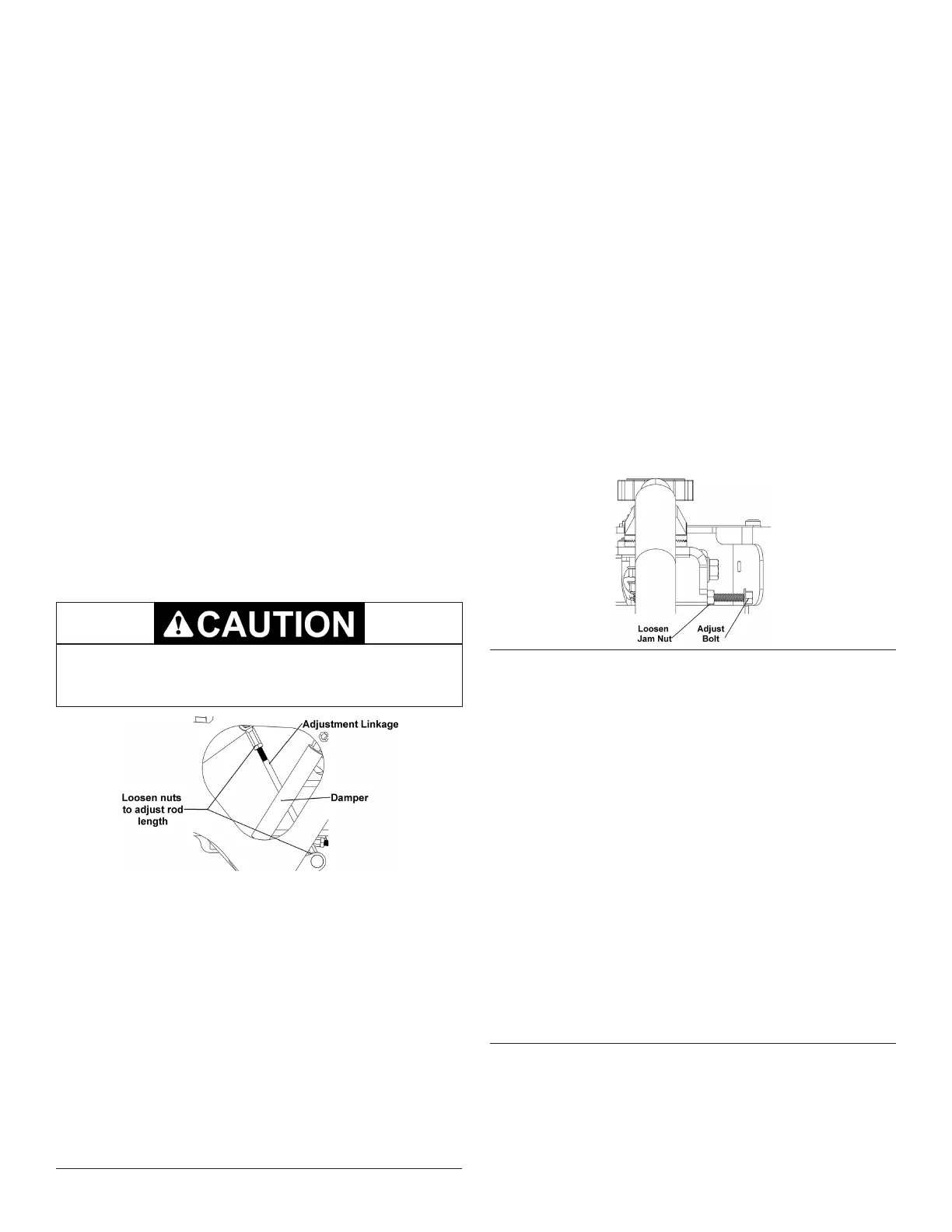

Neutral Adjustment

Neutral refers to the machine movement when the

engine is set to full throttle, parking brake is o, and

the control levers are in the neutral position.

The machine should not move forward or backward

in this state. If it does, the neutral setting must be

adjusted by using the Return-to-Neutral (RTN) device

built into the linkage of the hydraulic pump.

Preferred Method

1. Lift the rear drive wheels o the ground using a

jack and stands.

2. Lift Seat

3. Loosen Top (Left Hand Thread) and Bottom

(Right Hand Thread) 5/16 nuts on the short Rod

with a ½” wrench

a. If wheels are moving Forward turn

counterclockwise to lengthen rod.

b. If wheels are turning in Reverse turn rod

clockwise to shorten rod.

4. Once Wheels are in Neutral tighten 5/16 Jam

nuts

5. Check tracking and adjust if necessary.

DO NOT adjust rod connected directly to the

pump. ONLY make adjustments to the linkage

shown.

Alternate Method

1. Lift the rear drive wheels o the ground using a

jack and stands.

2. Remove rear wheels

3. Loosen the ¼” Allen bolt on the pump.

4. Rotate the RTN device on the pump

corresponding to the wheel that needs

adjustment. Stop when the neutral position is

found.

5. Retighten the ¼” Allen bolt. Do not over tighten.

6. Check tracking and adjust if necessary.

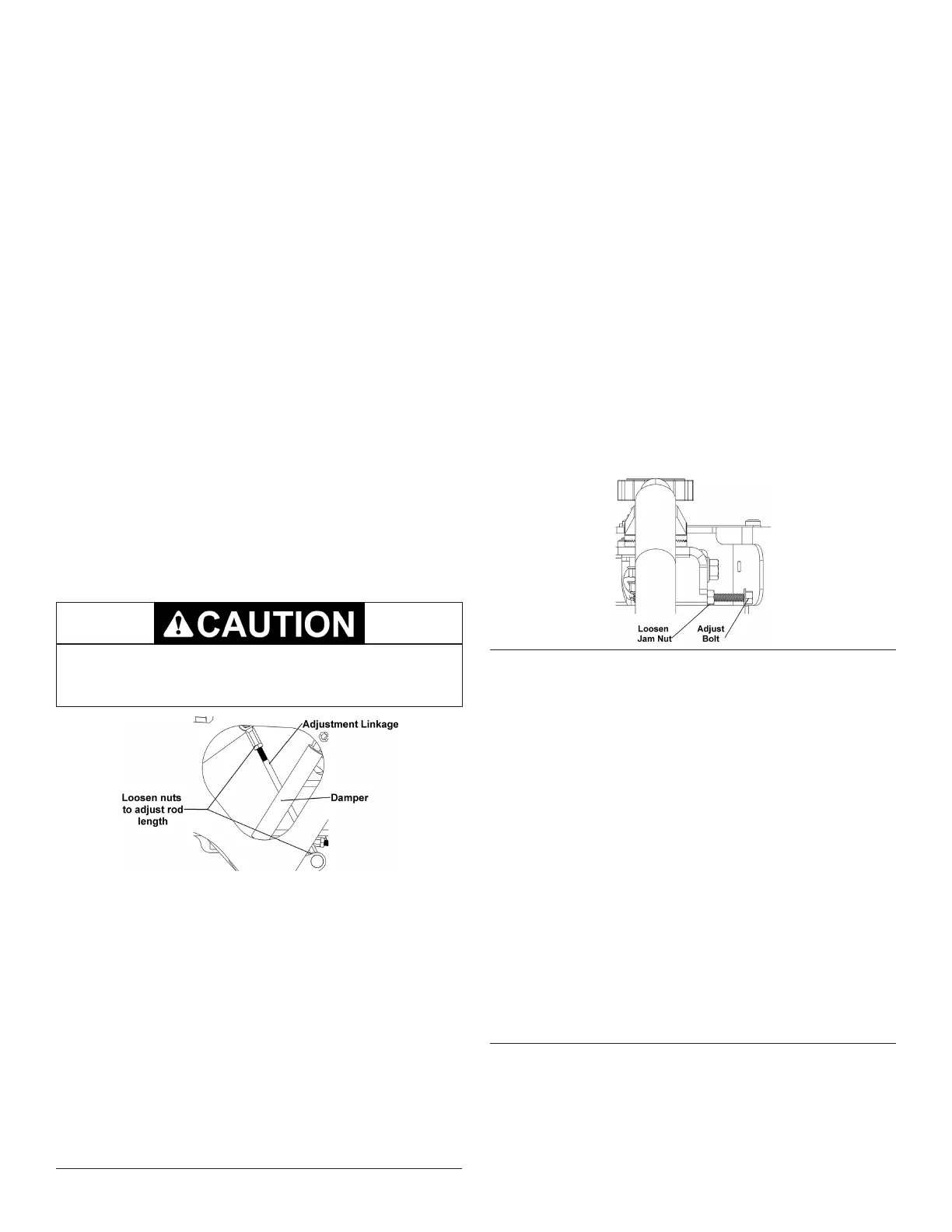

Tracking Adjustment

Check Machine Tracking

1. Ensure rear tire pressure is equal on both sides.

2. Drive at full throttle in a level parking lot.

3. Check if the machine drives straight when both

control levers are in the full speed position. If it

does not, tracking adjustment is needed

Adjust Machine Tracking

1. Ensure machine is parked and engine is o.

2. Use a 7/16” wrench to loosen the ¼” Jam nut

on the control tracking adjust

3. Use a 3/8” wrench to adjust ¼” tracking bolt

a. If machine tracks to the left: loosen the right

tracking bolt or tighten the left tracking bolt.

b. If machine tracks to the right: loosen the left

tracking bolt or tighten the right tracking bolt.

4. Tighten ¼” nut with 7/16” wrench.

Tire Maintenance and Pressure

• Excessively worn tire tread is dangerous on all

hills. Replace drive tires with less than 3/32” of

any tread groove left.

• Use tires with the tread pattern recommended

by Wright Mfg., Inc. only.

• Keep the drive tire pressure between 12-18 psi.

Factory setting is 18 psi.

• Always check deck pitch after adjusting tire

pressure

• Higher pressures cause the tires to have less

traction, decreasing safety, speed and ride

quality

• Front Casters are equipped with non-pneumatic

tires and do not require any air. They do not

have any tread but should be replaced when

excessively worn.

Troubleshoot No-Start Condition

1. Check that the battery is fully charged. If the

battery repeatedly dies, check the regulator

and charge wire going from the regulator to the

starter battery stud.

Loading...

Loading...