www.wto-tools.comB80000-0 ENG12

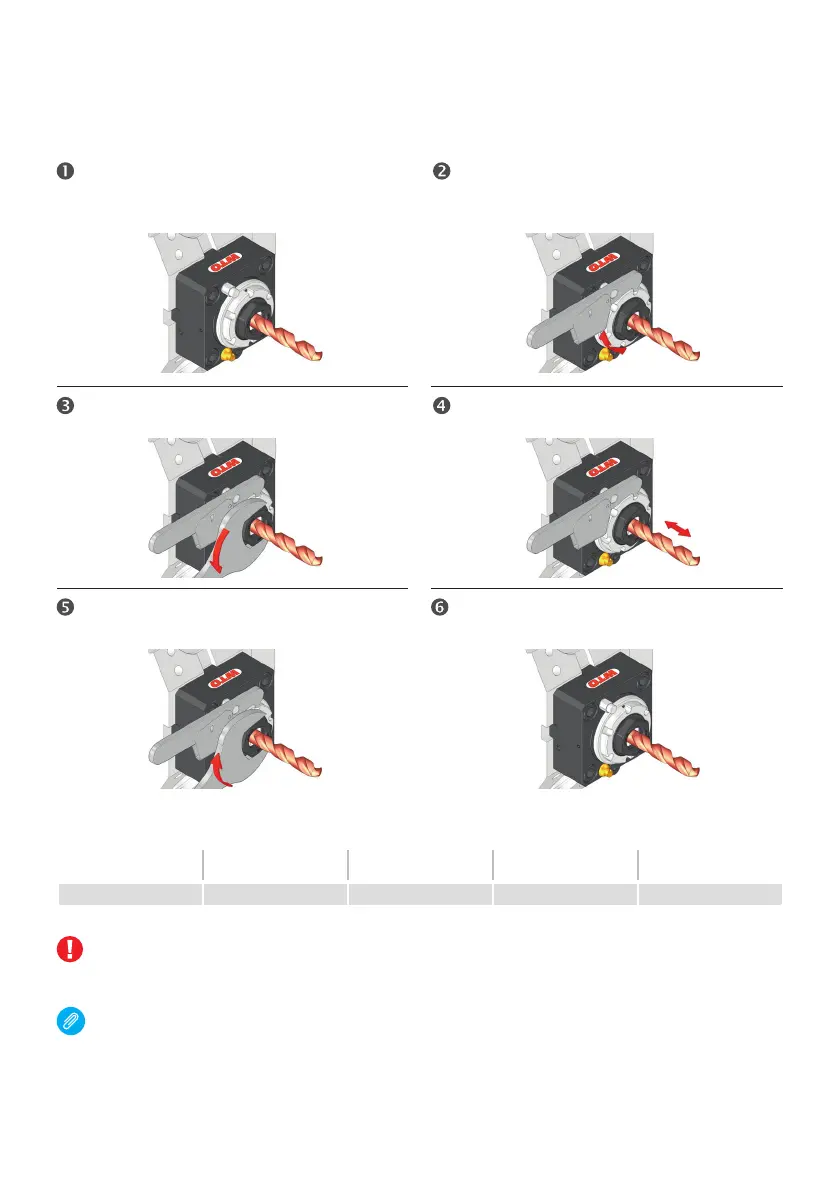

3.3 Changing the cutting tool

Rotate turret into machining position

(released machine drive)

Put on one-hand wrench and rotate DTH

spindle by hand until it locks into the

spindle nose

Release clamping nut with spanner

wrench

Change cutting tool

Tighten clamping nut with spanner

wrench. Follow torque recommendation!

Remove spanner wrench and

one-hand wrench

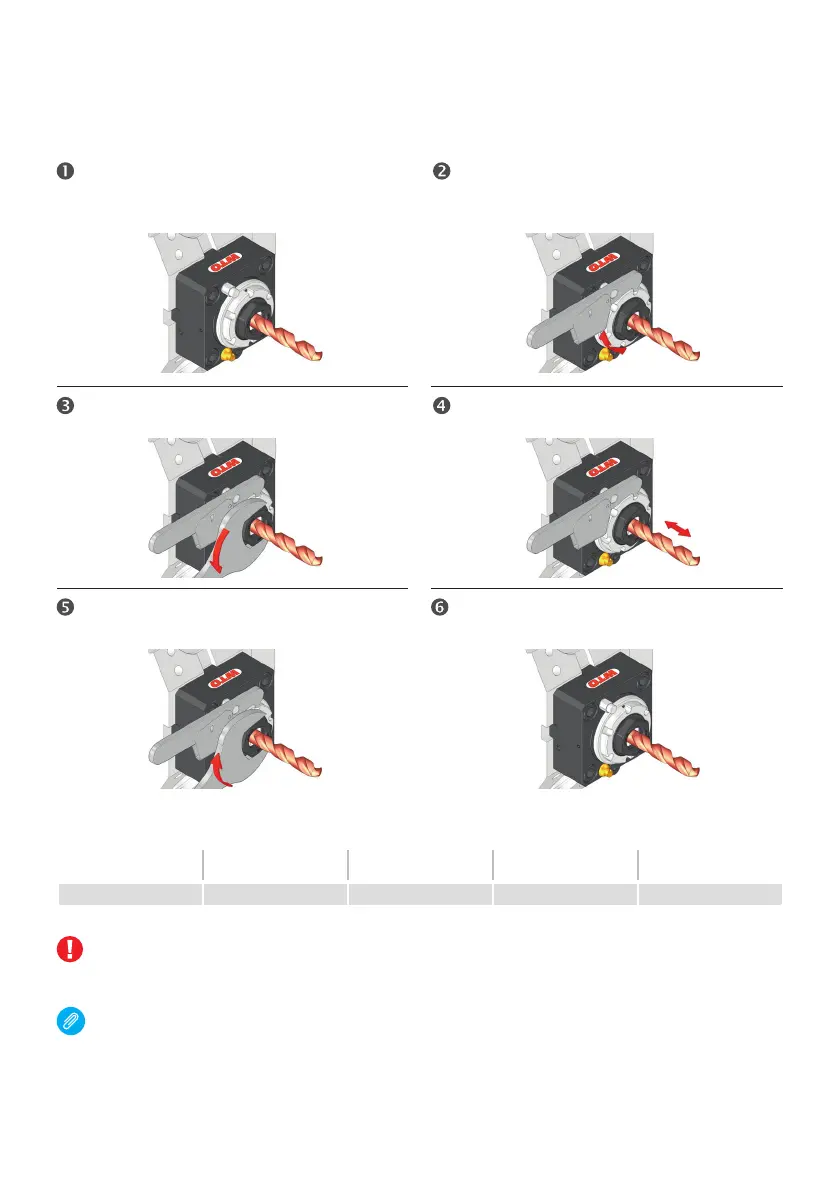

NOTICE

Never clamp oversize tool shanks. Never use a ø 12-11 mm collet to clamp a shank

ø 12.2mm. Rather use the next bigger collet, in that case ø 13-12 mm!

Improper handling causes poor runout and damage of the clamping nut!

WARNING

Tighten the clamping nut only when holding the spindle!

ER-20QF ER-25QF ER-32QF ER-40QF ER-50QF

80 Nm 110 Nm 140 Nm 180 Nm 240 Nm

59 ft-lb 81 ft-lb 103 ft-lb 133 ft-lb 177 ft-lb

Recommended tightening torque for the collet clamping nut

Loading...

Loading...