14

3 PLC connection

This chapter will introduce the connection method of OP and PLC.

The communication steps of PLC and OP:

1. Choose the PLC type communicating with OP. Check if the communication parameters of

OP and PLC are the same. The station no. of each part in the OP program should be same to

PLC.

2. Please disconnect the OP cable with PC after finish the downloading.

3. Connect OP and PLC with PLC cable, power on them, OP starts to work.

3-1.Xinje XC series PLC

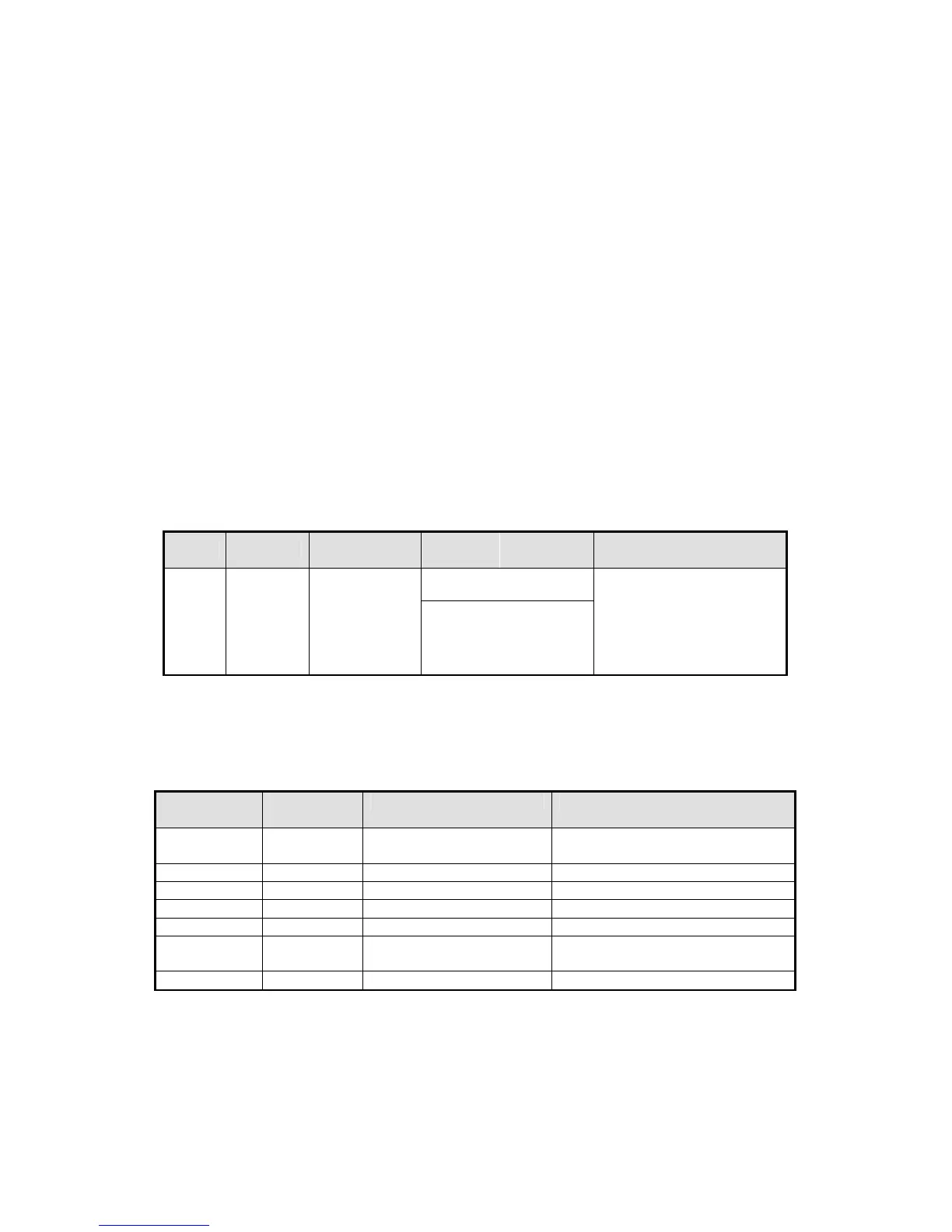

3-1-1.Connection unit

Series

CPU

Connected

module

Port Cable Choose PLC type in OP20

XC

XC1

XC2

XC3

XC5

XCM

XCC

CPU

RS232

Diagram 1

Xinje XC series

RS485

Diagram 2

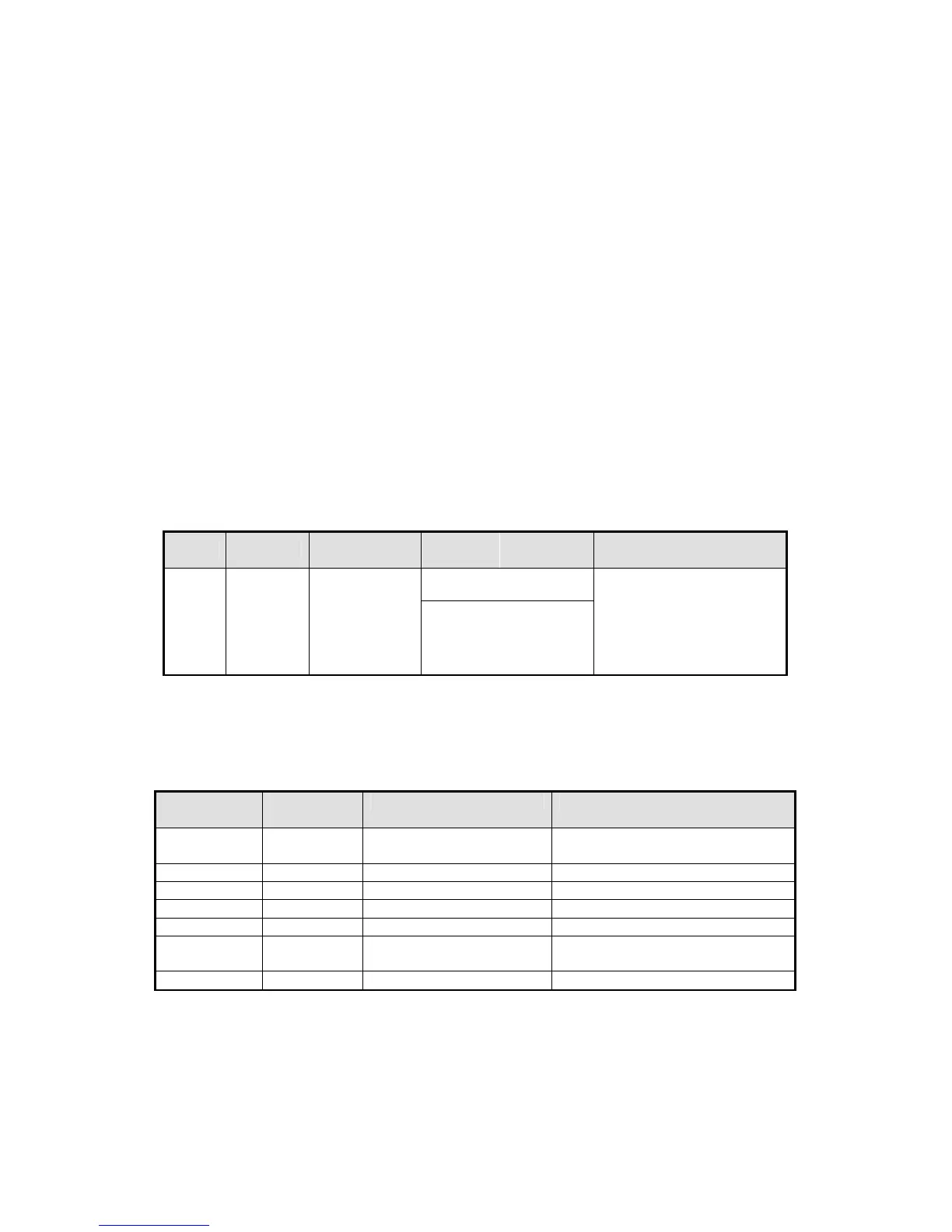

3-1-2.Communication parameter

OP software default settings:

Parameter Recommend

Settings

Choices of settings Note

PLC model XC series FC/XC series Choose correct PLC model

communicating with OP

Port RS232 RS232/RS485

Data bit 8 7/8 Accord with PLC port settings

Stop bit 1 1/2 Accord with PLC port settings

Parity Even parity Even /odd/no parity Accord with PLC port settings

Baud rate 19200 4800/38400/9600/115200

/19200/187500

Accord with PLC port settings

Station no. 1 0~255

Default communication parameters of Xinje XC series PLC: 19200, 8, 1, even parity, station

no.1.

Loading...

Loading...