16

7+Series Version 2.0

Conductivity Calibration

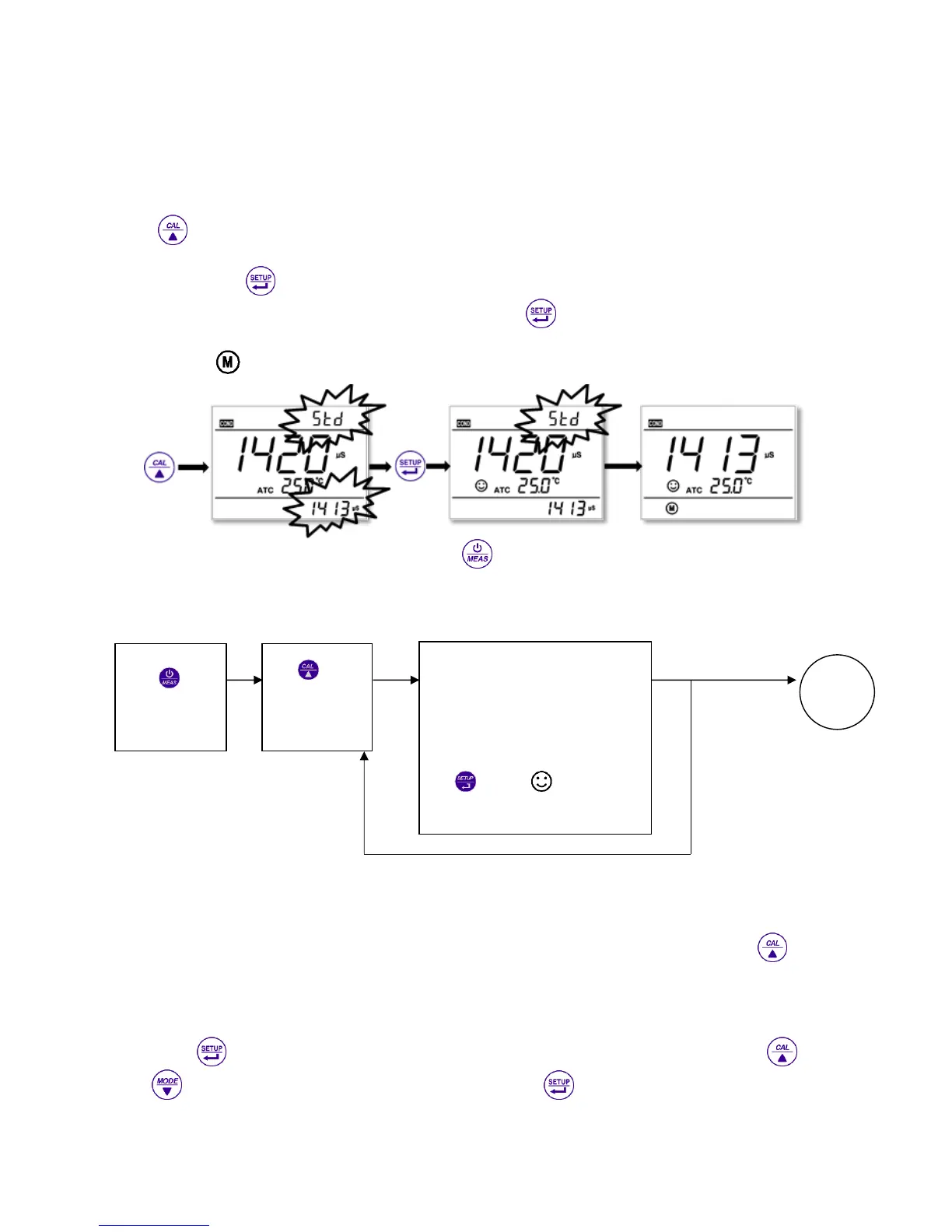

example of calibration at 1413μS/cm

Rinse conductivity electrodes in pure water, allow it to dry, wash with a little of standard solution and submerge it in

standard solution. Stir the solution briefly and allow it to stay in the solution until a stable reading is reached.

Press key to enter into the calibration mode. The meter’s display will show blinking “std” at the top right, and

scanning and locking process of calibration solution at the bottom right.

Er 2 appears if press key before the value is stable.

When the meter locks 1413 μS, stability icon displays on LCD. Press key to calibrate the meter. End icon appears

after calibration is done. The meter returns to the measurement mode

and LCD shows icon at the bottom left.

If return from calibration mode without calibration, press key to return to the measurement mode without

calibration.

For multi-point calibration repeat the procedure.

Customer calibration

example of calibration at 147μS/cm

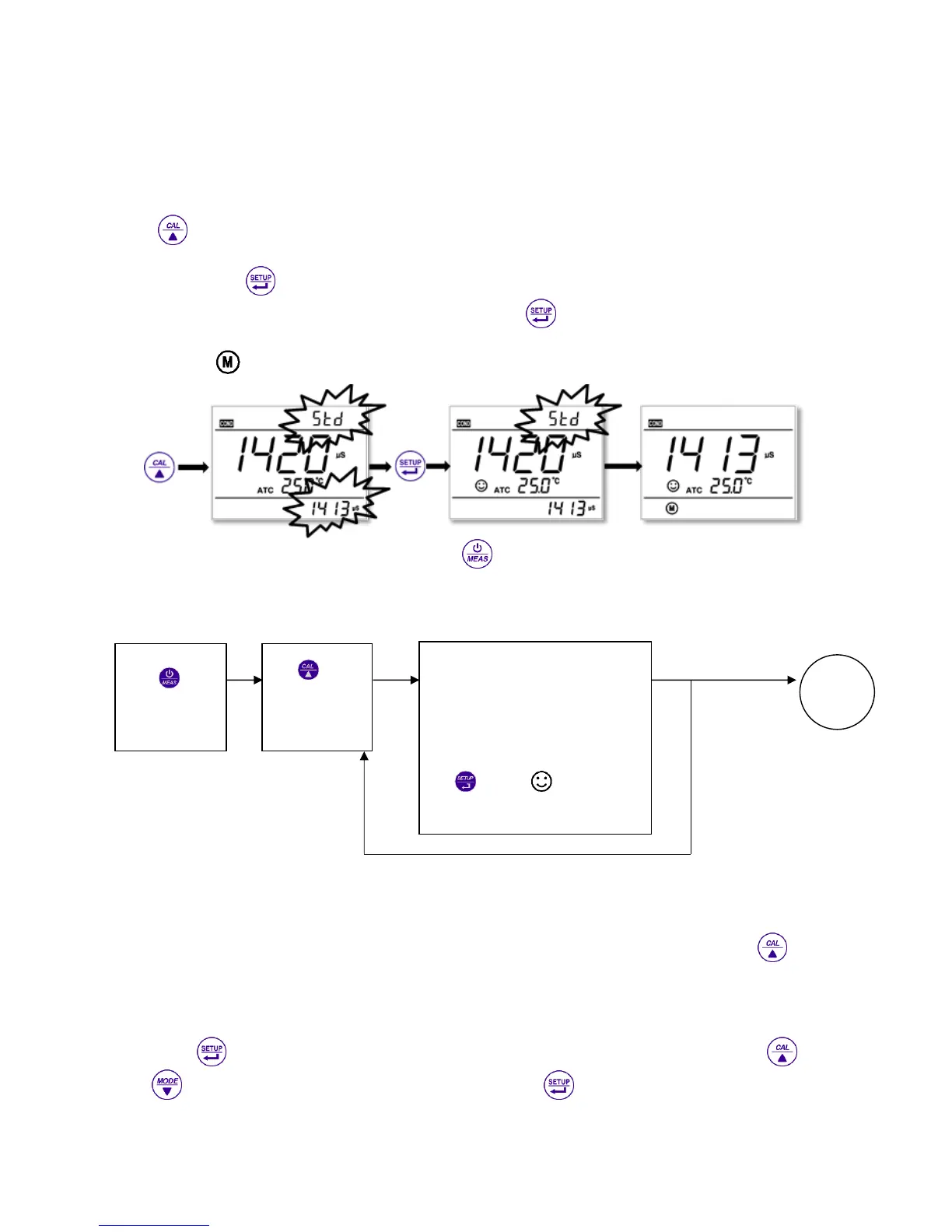

Select CUS in the setup menu P2.2; the meter enters into customer-defined calibration mode. When press LCD

shows blinking CUS at the top right, indicating that the meter enters into customer-defined calibration.

Rinse the electrode in pure water, allow it to dry, and submerge it in 147 μS/cm standard solution. Stir the solution

briefly and allow it to stay in the solution until a stable reading is reached and stability icon appears on LCD.

When press key, the measuring value blinks. “CUS” icon appears at the right top of the screen. Press

and key to adjust the measuring value to 147 μS/cm, and press key to calibrate the meter. After the

calibration is done, the screen shows “End” icon and returns to the measurement mode.

Note: When there is no temperature sensor and manual temperature compensation (MTC) is adopted, the

Loading...

Loading...