VESDA by Xtralis VESDAVLSProduct Guide

www.xtralis.com 37

11 Maintenance

To maintain the VESDA VLS at its peak performance the maintenance schedule given below should be

followed. Maintenance can be conducted by the original installer, VESDA distributor or an approved service

contractor. To work effectively the VESDA VLS detector needs to be supported by a well designed Pipe

Network. The Maintenance Schedule includes the maintenance required for the Pipe Network. Given below is

a suggested Maintenance Schedule for the VESDA VLS detector. Local codes and standards, and site

conditions take precedence in preparing a Maintenance Schedule.

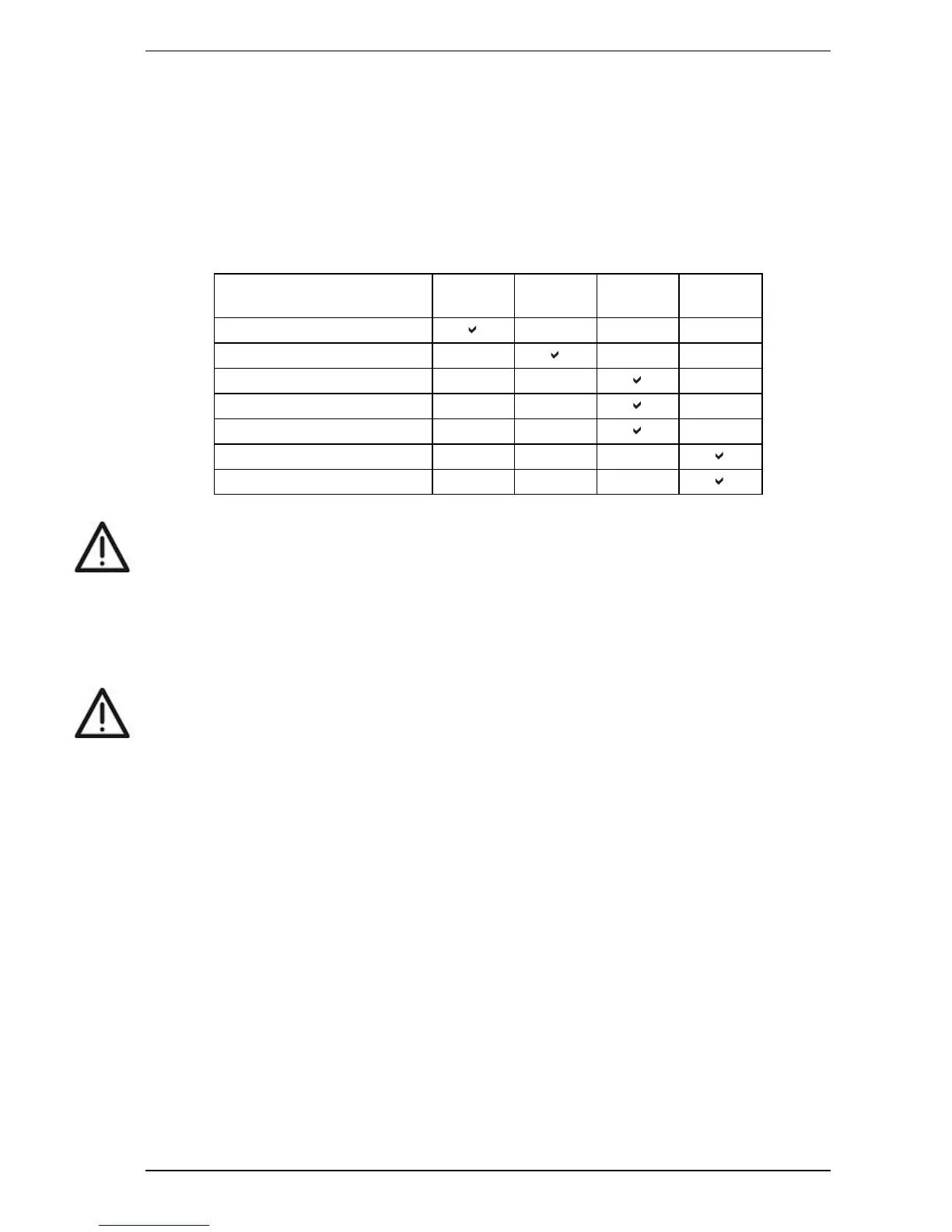

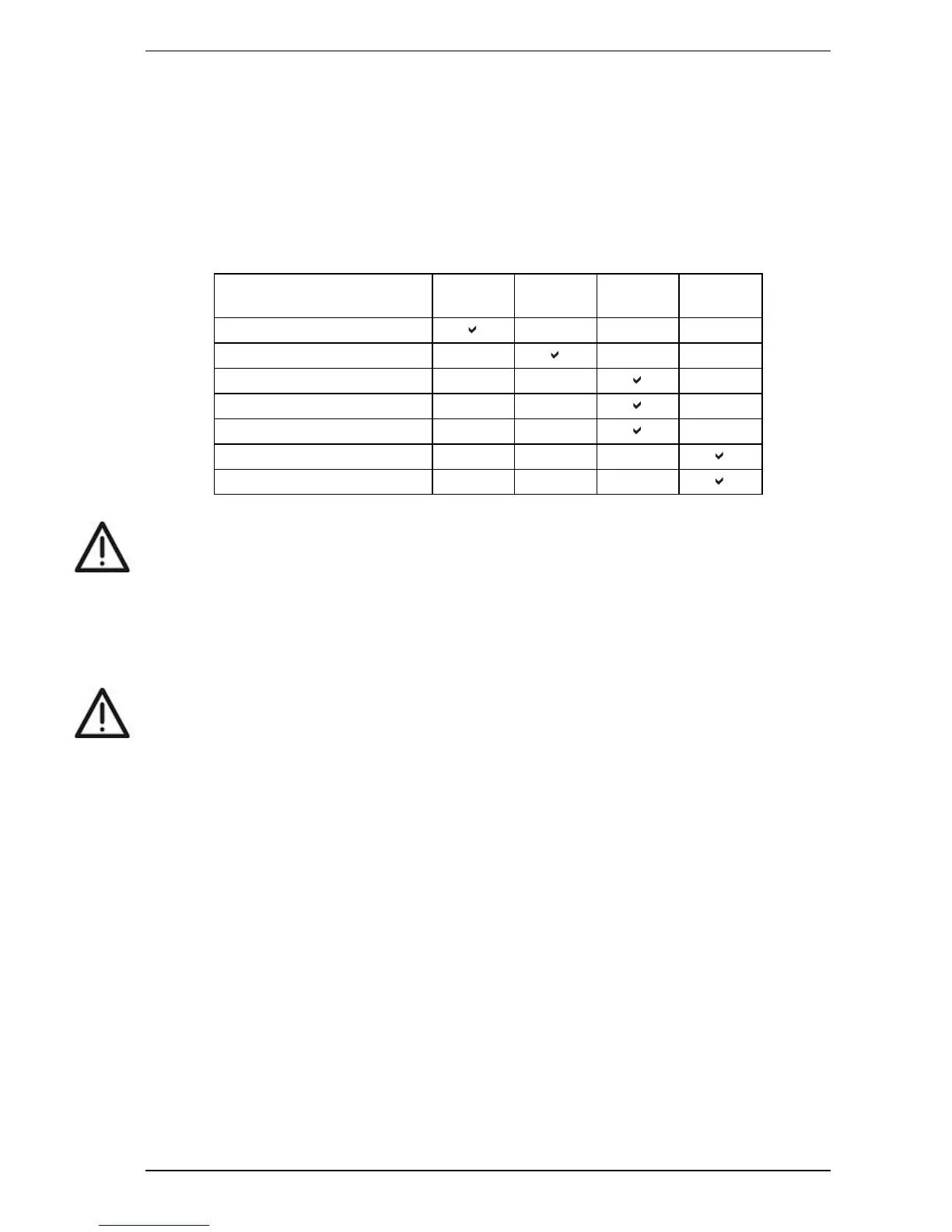

Maintenance Check Quarterly Six

Monthly

Annual Biennial

Power Supply

Check Pipe Network

Filter Inspection

Pipe Integrity Smoke Test

Check Pipe Flow

Clean Sampling Point

Flush Pipe Network

Table 11-1: Suggested maintenance schedule for VESDA VLS detector

Caution: While a VESDA Zone is isolated, no fire warnings will be issued by the VESDA VLS detector

and any fire will go undetected. Prior to any maintenance or testing:

l Inform appropriate supervising authority about the risk associated with isolating a VESDA Zone.

l Check to see if the VESDA VLS detector is also being used by third party

l Ensure that any ancillary devices dependent on the VESDA VLS detector are enabled by the isolation

before work is begun.

Attention : Lorsqu'une zone VESDA est isolée, aucun avertissement de feu ne sera émis par le détecteur

VESDA VLS et aucun incendie ne pourra être détecté. Avant tout entretien ou essai :

l Informez l'autorité compétente du risque associé à l'isolement d'une zone VESDA.

l Vérifiez si le détecteur VESDA VLS est également utilisé par une tierce partie.

l Vérifiez que tous les équipements auxiliaires dépendants du détecteur VESDA VLS sont activés par

l'isolation avant le début des travaux.

Loading...

Loading...