VESDA by Xtralis VESDAVLSProduct Guide

www.xtralis.com 39

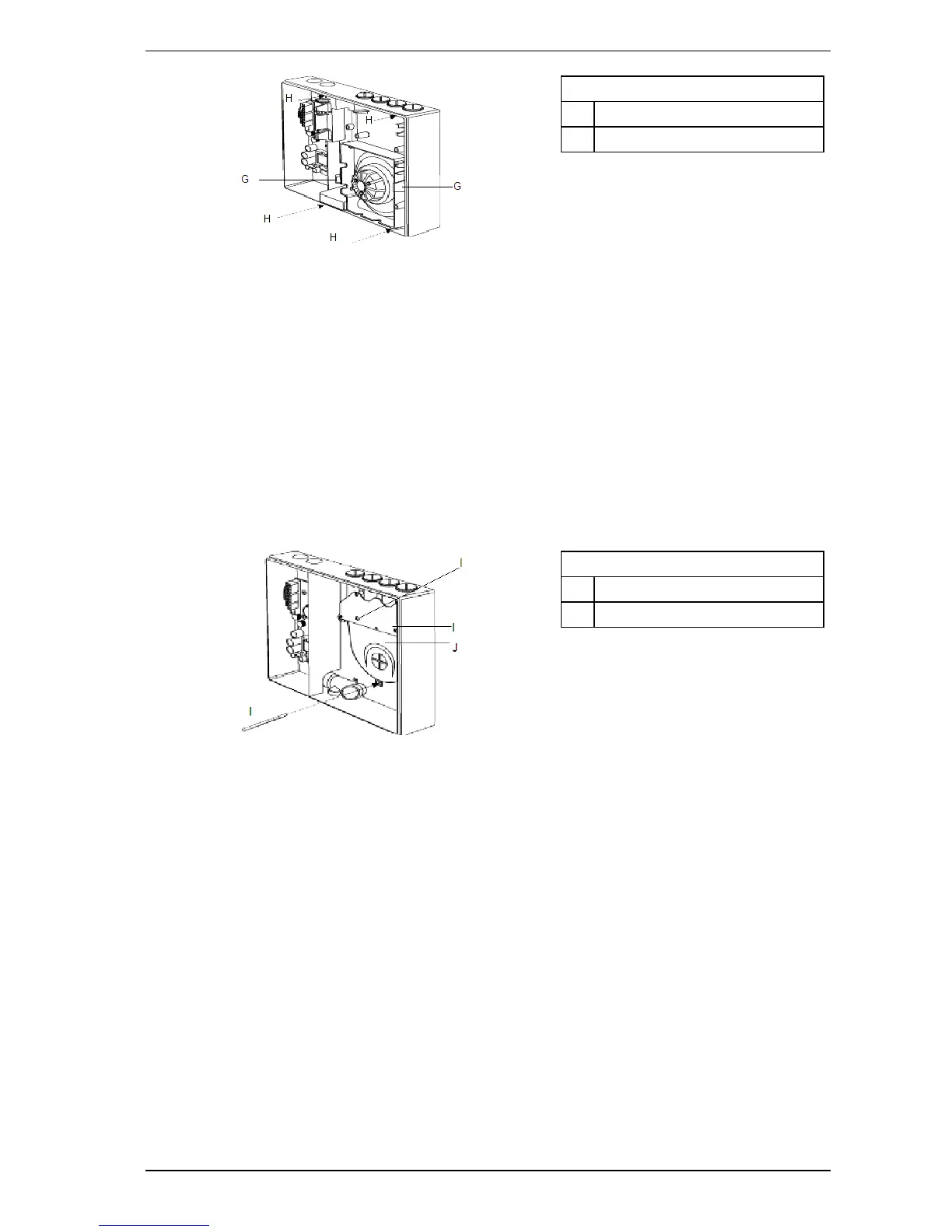

Legend

G 2 Manifold retaining screws

H 4 Retaining tabs

Figure 11-3: Remove the chassis

9. The manifold is held in place by four tabs (H). Use a flat head screw driver to lever out the tabs near the

head termination card, and lift up that end of the manifold. While holding the manifold up, use the screw

driver to lever out the other two tabs. This is a tight fit. As you lift out the manifold note that the flow

sensor and scanner cables disappear through a hole in the manifold. Once the manifold has been lifted

out you can see that these cables are still connected to the flow sensor board on the air inlet pipe

manifold.

Note: The chassis consists of the detection chamber, head processor card and flow sensors. These are

factory calibrated as a matched set and must not be separated. Separating the set and replacing it

with components from another VESDA VLS will cause the detector to malfunction. This will require

the chassis to be returned to the factory.

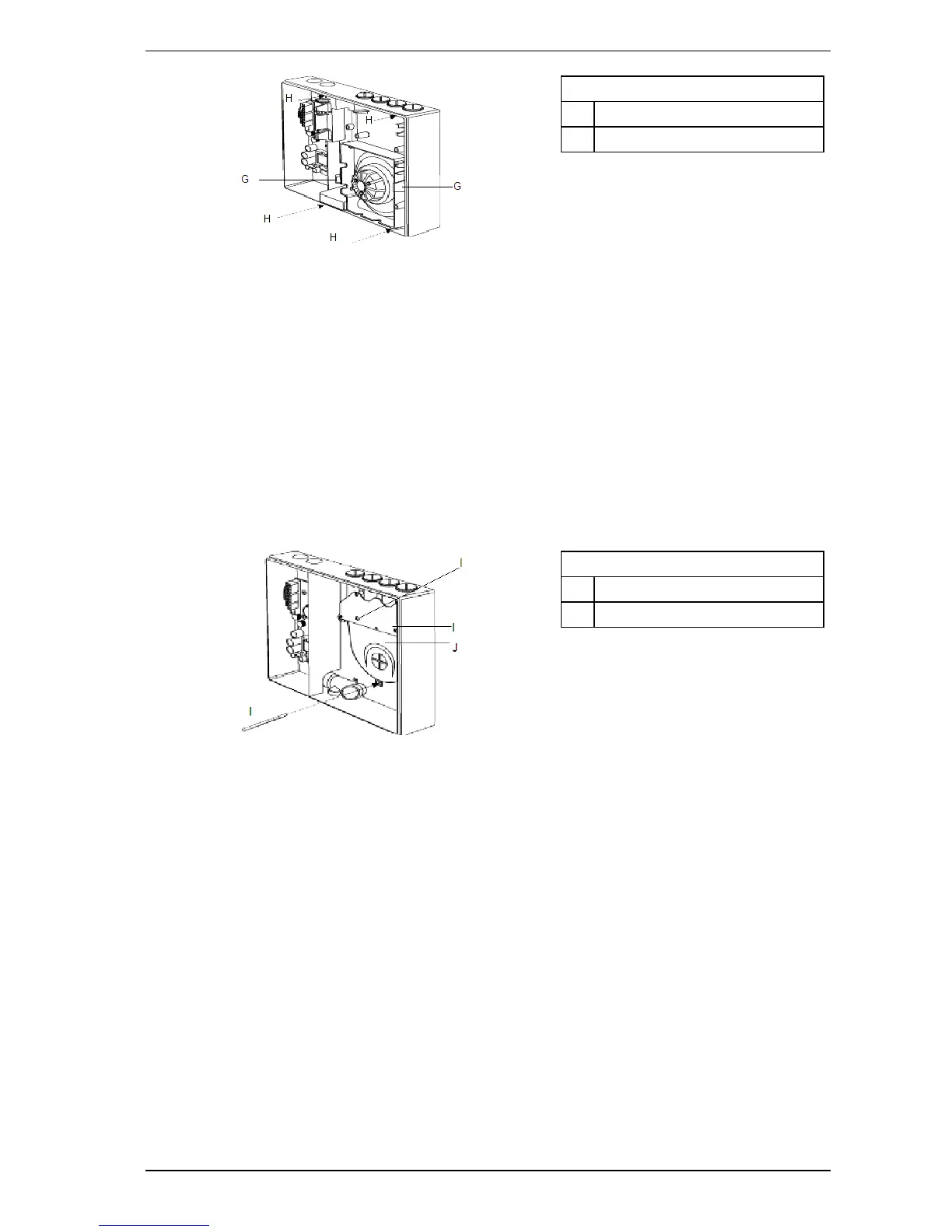

10. Unscrew the three screws holding the pipe inlet in place (I). Two screws are hidden in holes in the PCB

(Flow sensor board).

11. Lift the air inlet up and out.

Legend

I 3 Pipe-inlet retaining screws

J Pipe inlet manifold

Figure 11-4: Removing pipe inlet manifold

12. Attach the replacement manifold and chassis by reversing the procedure above.

13. Configure the VESDA VLS using Xtralis VSC by highlighting the detector in the Device Tree Window

and selecting Restore Node Configuration from the Device Menu, or reprogram the detector manually

using the LCD Programmer

Note: Power cables must be the last to be connected. Connecting the power cables before all of the data

cables can lead the unit to malfunction, requiring the VESDA VLS to be returned to the factory.

Loading...

Loading...