VESDA by Xtralis VESDA PipeNetwork Design Guide

www.xtralis.com 13

4.4.3 Return Air Grille Sampling

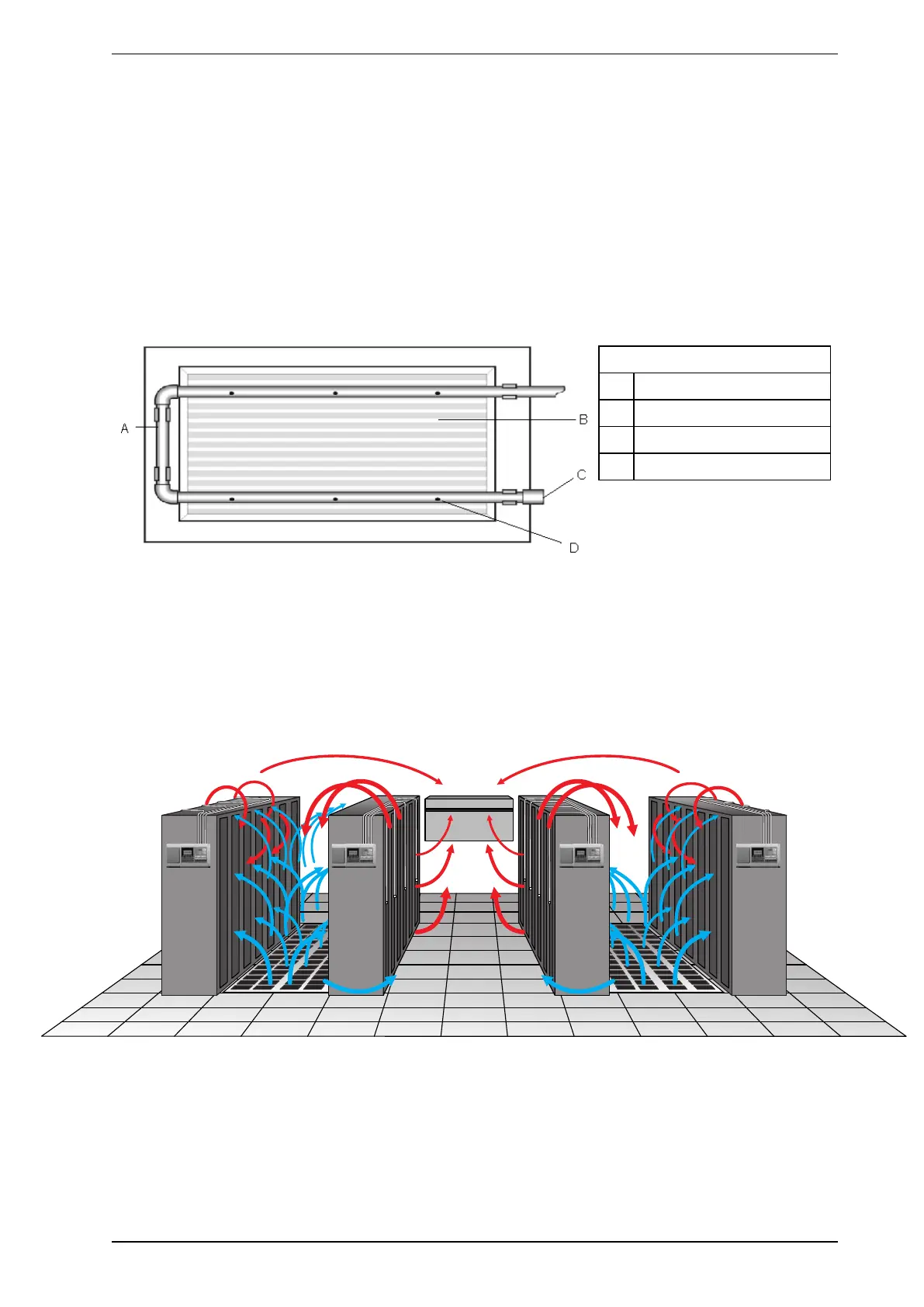

The sampling pipe is placed over the return air grille of a duct or an Air Handling Unit (AHU). Figure 4-8

illustrates pipe mounting over the return air grille. The number of AHUs that can be covered by different

detectors is dependent on the suction power of the AHU and also on the size of the return air grille.

Recommendations:

l a VESDA VLP or VESDA VLS detector should not monitor more than four AHUs

l a VESDA VLC should not monitor more than two AHUs,

l a VESDA VLF should not monitor more than one AHU.

l the detectors should be in close proximity to the AHUs.

l transport time should be less than 60 seconds.

l sampling hole sensitivities should be maintained.

Legend

A Sampling pipe

B Return grill

C End cap without hole

D Sampling hole

Figure 4-8: Return air sampling over a return air grille

Note: Socket unions are also used where it is important to have correct orientation of sampling holes.

4.4.4 Hot - Cold Aisle Sampling

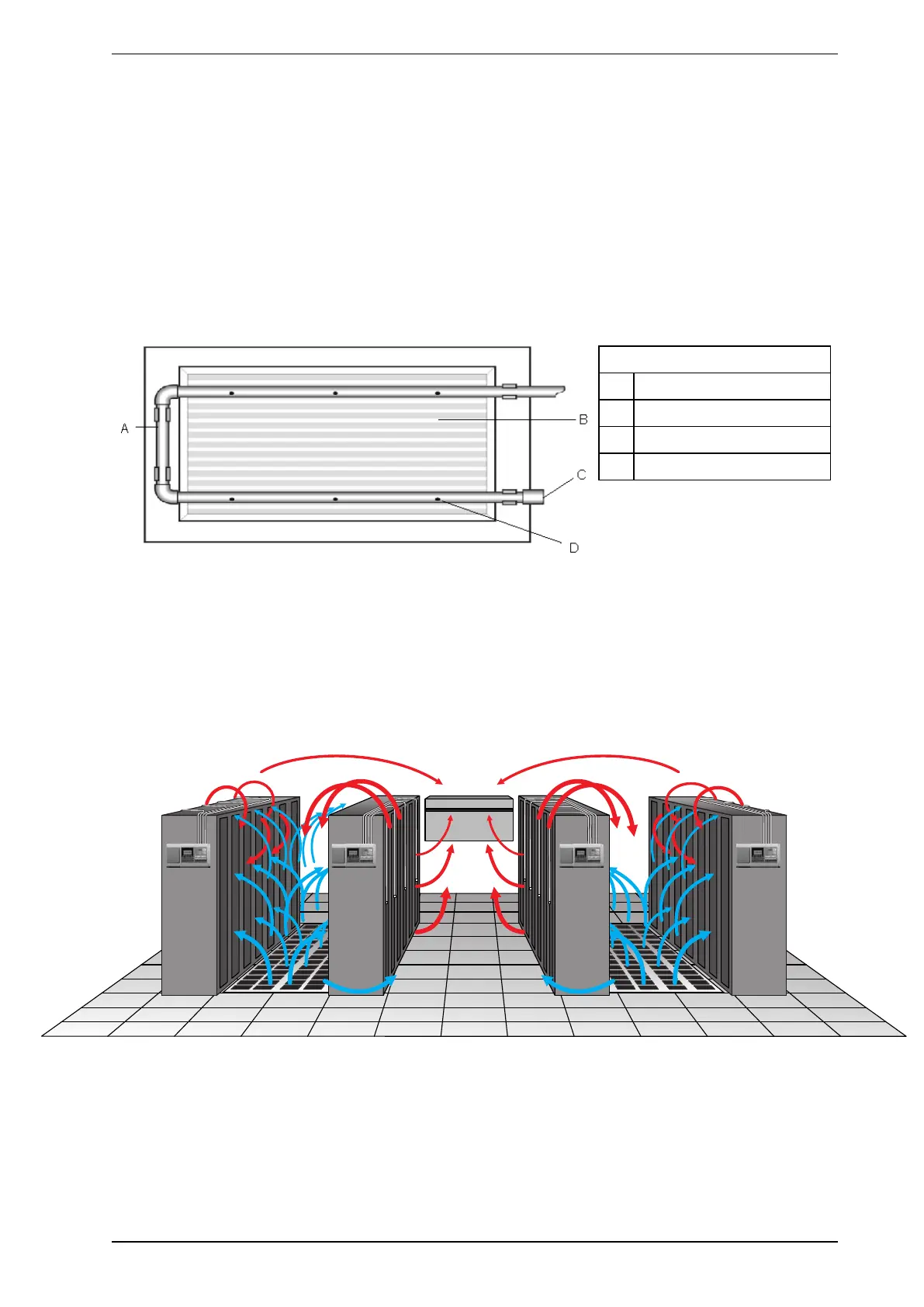

In hot - cold aisle systems, the cabinets are adjoined into a series of rows, resting on a raised floor. The fronts

of the racks face each other and become cold aisles, due to the front-to-back heat dissipation of rack servers.

Hot - cold aisle protocol can be implemented with underfloor, overhead, horizontal displacement, or local air

distribution systems.

Figure 4-9: Hot - Cold Aisle System

l Primary Sampling: Rear of racks, Air-return grills (CRAC, Ceiling)

l Secondary Sampling: ceiling.

Loading...

Loading...