OIL PUMP

5-44

EAS24980

CHECKING THE OIL DELIVERY PIPES

1. Check:

• Oil delivery pipe “1”

•Oil pipe “2”

Damage → Replace.

Obstruction → Wash and blow out with

compressed air.

EAS24990

CHECKING THE OIL STRAINER

1. Check:

• Oil strainer “1”

Damage → Replace.

Contaminants → Clean with solvent.

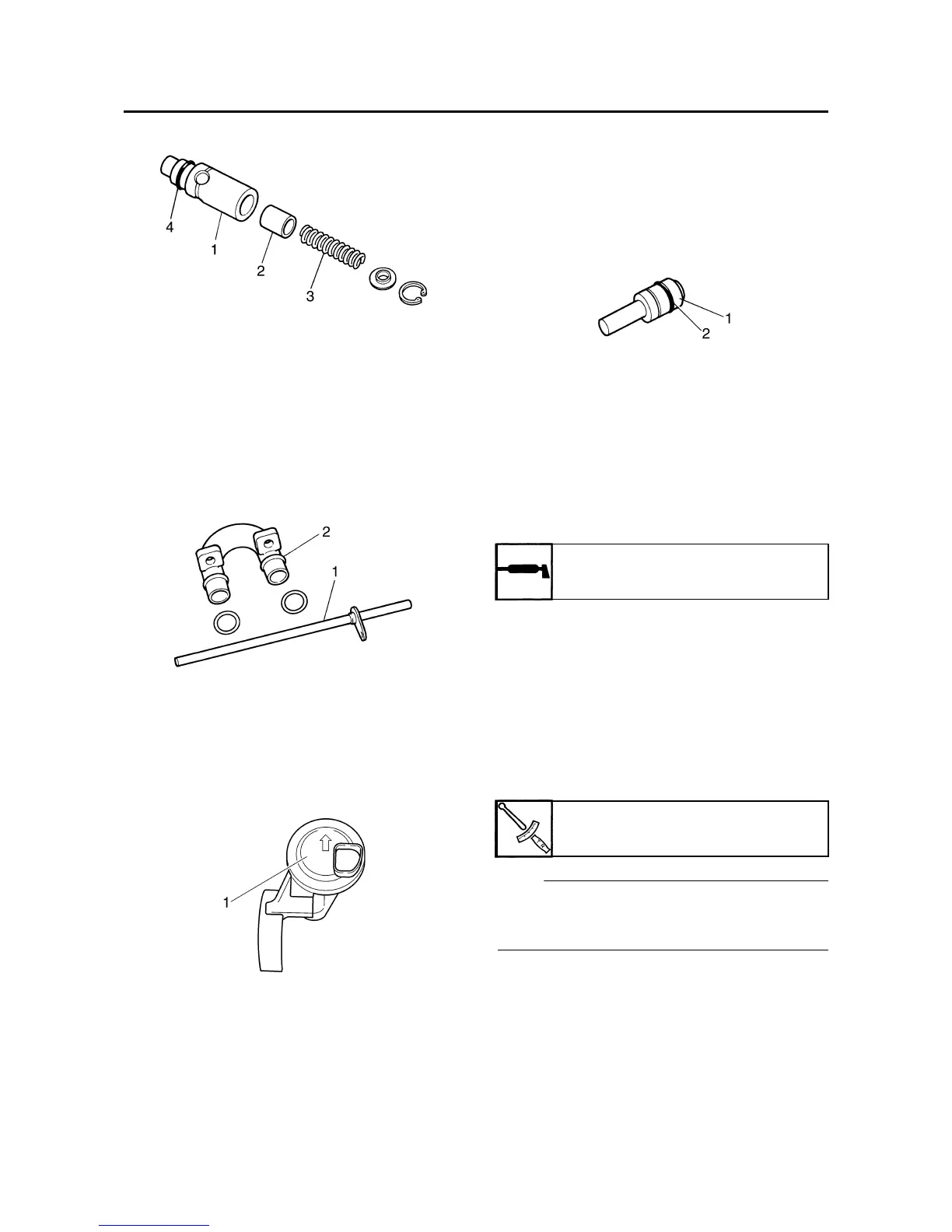

EAS4S81016

CHECKING THE OIL NOZZLES

The following procedure applies to all of the oil

nozzles.

1. Check:

• Oil nozzle “1”

Damage/wear → Replace the oil nozzle.

• O-ring “2”

Damage/wear → Replace.

• Oil nozzle passage

Obstruction → Blow out with compressed

air.

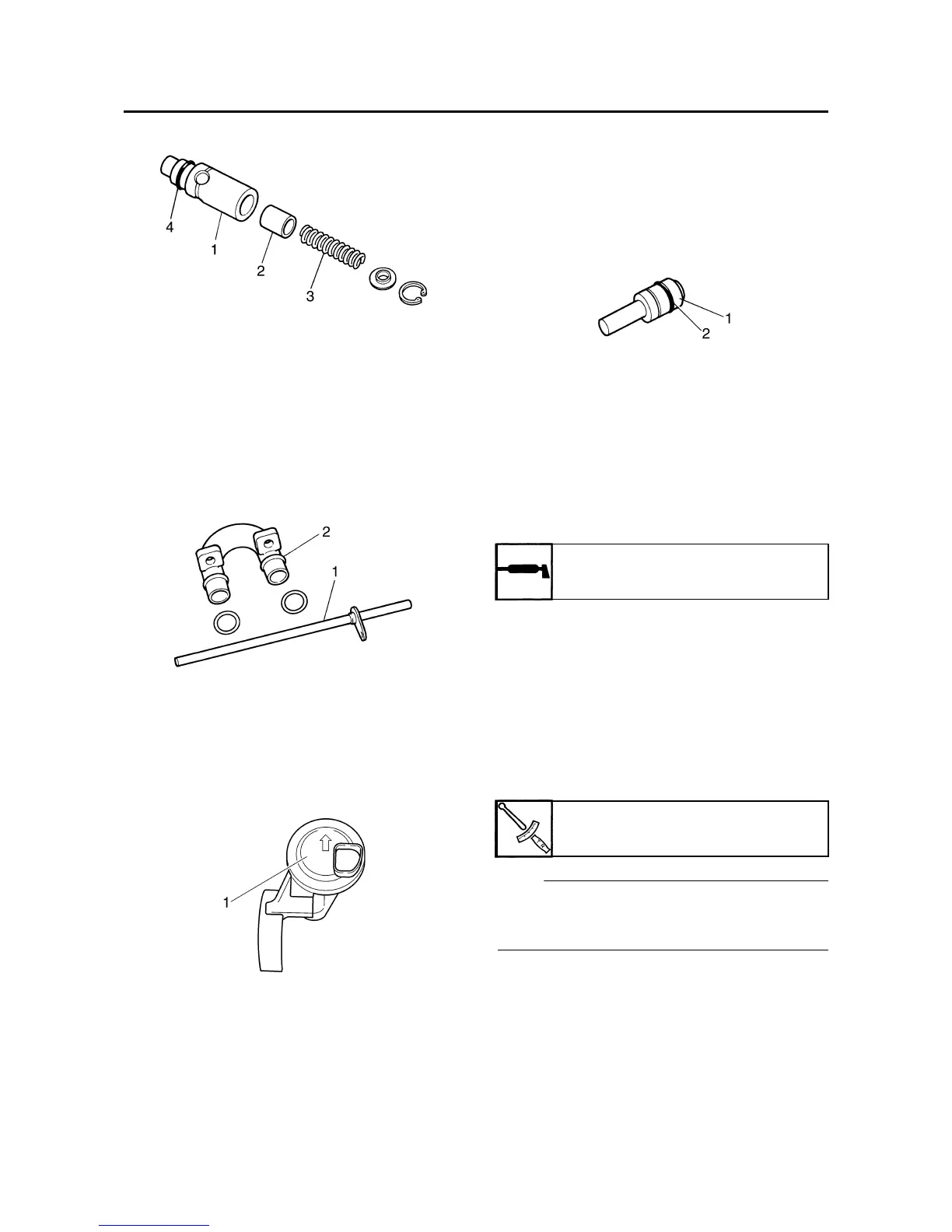

EAS25010

ASSEMBLING THE OIL PUMP

1. Lubricate:

• Inner rotor

• Outer rotor

• Oil pump shaft

(with the recommended lubricant)

2. Install:

• Oil pump housing “1”

• Oil pump shaft “2”

• Washer “3”

•Pin “4”

• Inner rotor “5”

• Outer rotor “6”

• Dowel pins “7”

• Oil pump cover “8”

• Oil pump housing screw

NOTE:

When installing the inner rotor, align the pin “4”

in the oil pump shaft with the groove “a” in the

inner rotor “5”.

Recommended lubricant

Engine oil

Oil pump housing screw

12 Nm (1.2 m·kg, 8.7 ft·lb)

Loading...

Loading...