NOTE:

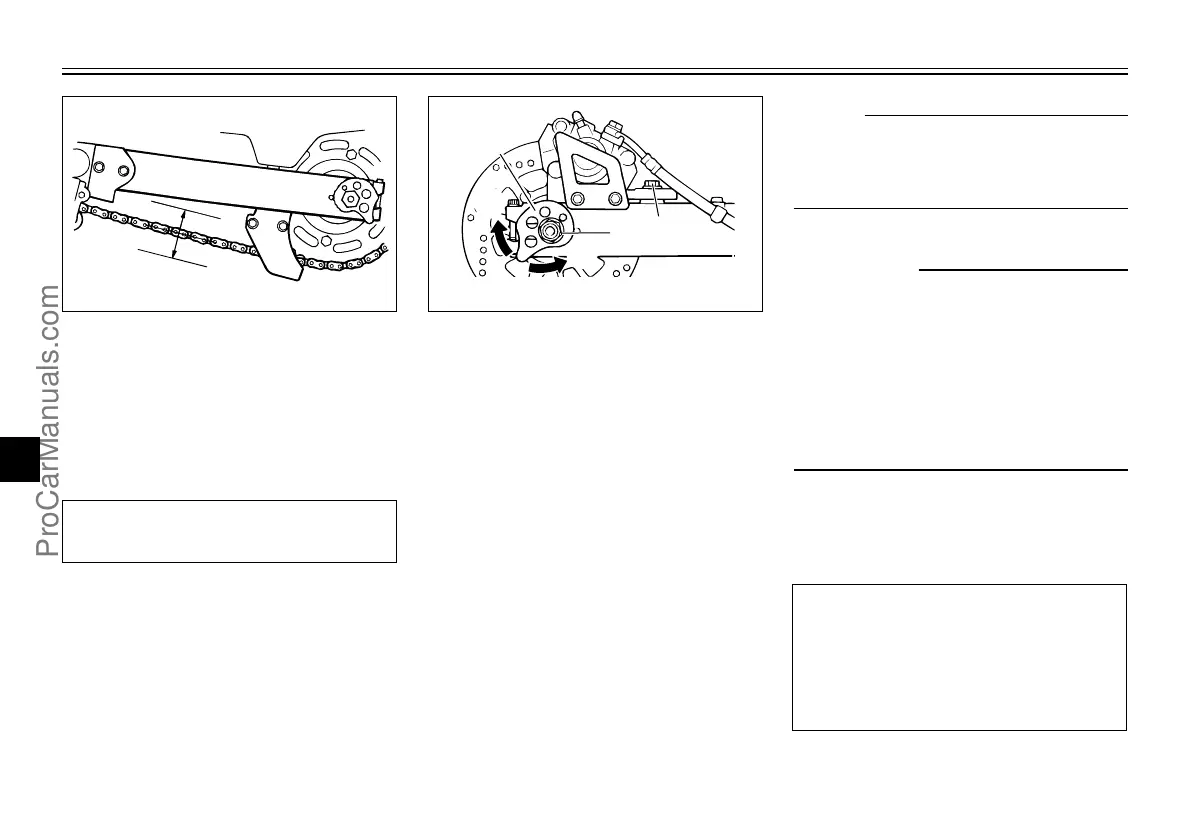

Make sure that both adjusting plates

are in the same position for proper

wheel alignment.

EC000096

cC

Improper drive chain slack will

overload the engine as well as

other vital parts of the motorcycle

and can lead to chain slippage or

breakage. To prevent this from

occurring, keep the drive chain

slack within the specified limits.

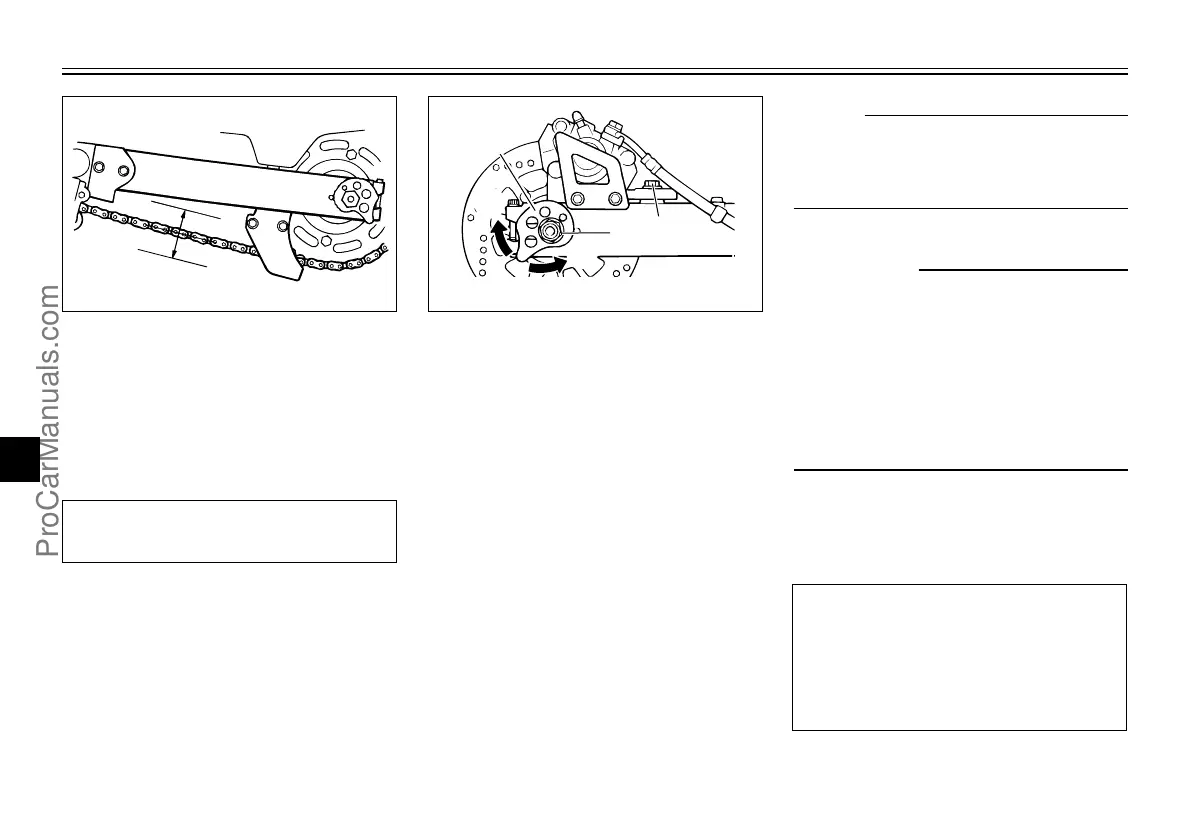

3. Tighten the axle nut and the

brake caliper bracket bolt to the

specified torques.

6-23

PERIODIC MAINTENANCE AND MINOR REPAIR

1

2

3

4

5

6

7

8

9

Tightening torques:

Axle nut:

105 Nm (10.5 m

0kg)

Brake caliper bracket bolt:

48 Nm (4.8 m0kg)

EAU01134

To adjust the drive chain slack

1. Loosen the axle nut and the

brake caliper bracket bolt.

2. To tighten the drive chain, turn

the adjusting plate on each side

of the swingarm in direction a.

To loosen the drive chain, turn

the adjusting plate on each side

of the swingarm in direction b,

and then push the rear wheel for-

ward.

1. Adjusting plate

2. Axle nut

3. Brake caliper bracket bolt

a. Drive chain slack

3. Move the rear wheel by pushing

the motorcycle to locate the tight-

est portion of the drive chain,

and then measure the drive

chain slack as shown.

4. If the drive chain slack is incor-

rect, adjust it as follows.

Drive chain slack:

30–40 mm

3WR-9-2A (E) 6 6/28/00 11:17 AM Page 24

ProCarManuals.com

Loading...

Loading...