CONNECTING RODS AND PISTONS

EB404403

CHECKING THE CYLINDERS AND PISTONS

The following procedure applies to all of

the cylinders and pistons.

1. Check:

• piston wall

• cylinder wall

Vertical scratches → Replace the

crankcases, and the piston and piston

rings as a set.

2. Measure:

• piston-to-cylinder clearance

▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼

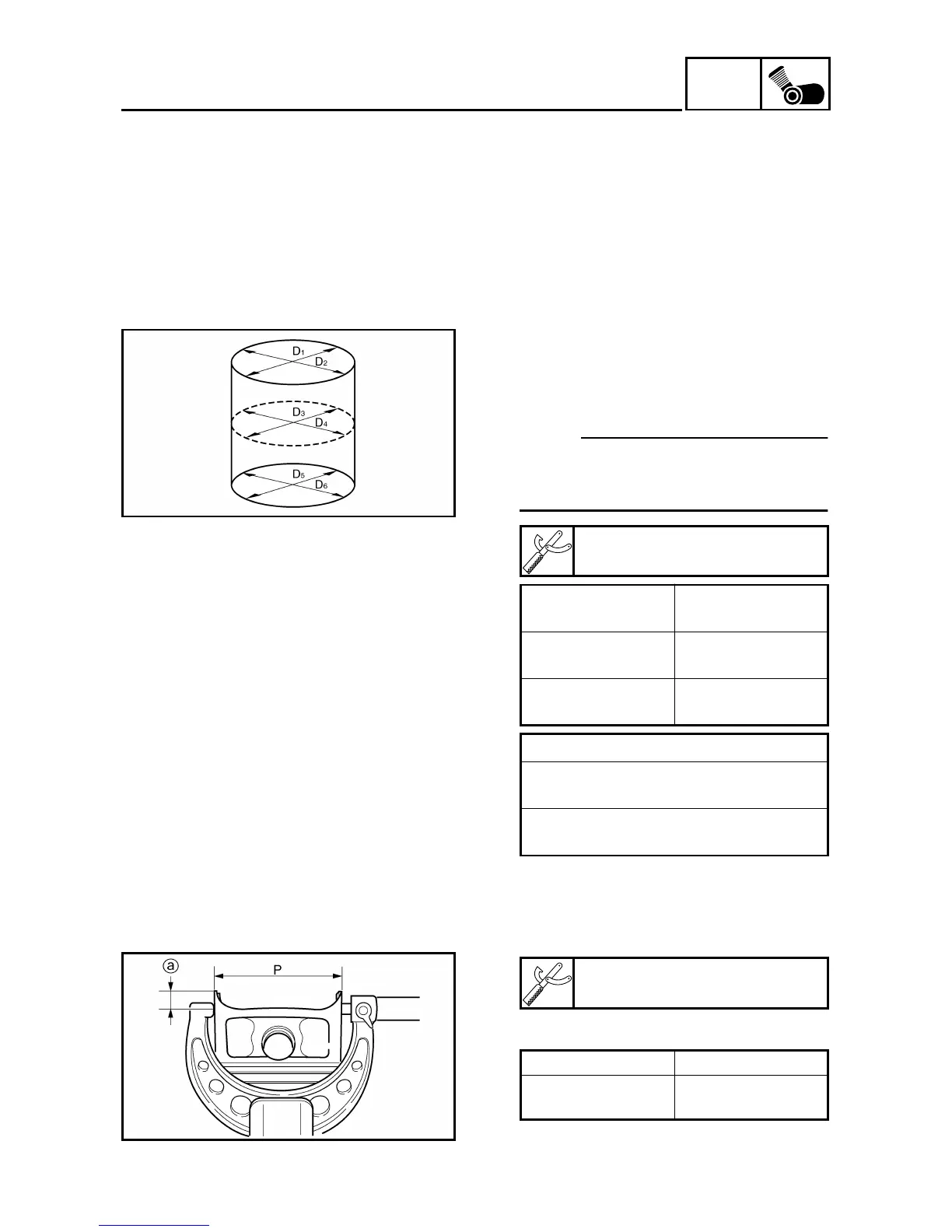

a. Measure cylinder bore “C” with the

cylinder bore gauge.

NOTE:

Measure cylinder bore “C” by taking

side-to-side and front-to-back measure-

ments of the cylinder. Then, find the

average of the measurements.

b. If out of specification, replace the

crankcases, and the pistons and pis-

ton rings as a set.

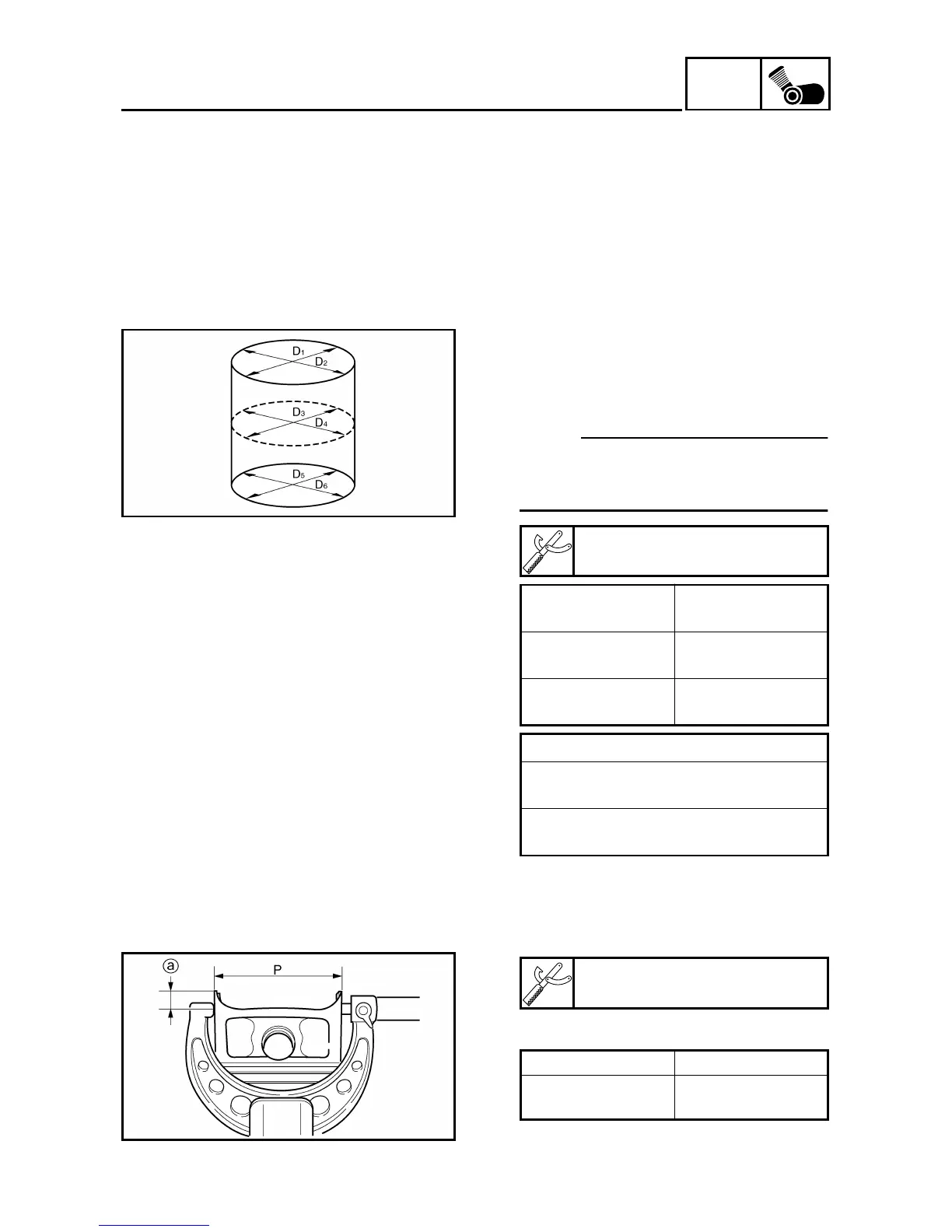

c. Measure piston skirt diameter “P”

with the micrometer.

a 10 mm (0.39 in) from the bottom edge

of the piston

d. If out of specification, replace the pis-

ton and piston rings as a set.

Cylinder bore gauge

90890-03017

Cylinder bore “C”

72.000 ~ 72.008 mm

(2.8346 ~ 2.8350 in)

Maximum taper

“T”

0.05 mm

(0.0016 in)

Out of round “R”

0.05 mm

(0.0016 in)

“C”= maximum of D1

~

D6

“T” = maximum of D1, or D2 – maxi-

mum of D

5 or D6

“R” = maximum of D1, D3 or D5 – mini-

mum of D

2, D4 or D6

Micrometer

90890-03008

Piston size “P”

Standard

71.954 ~ 71.972 mm

(2.8328 ~ 2.8335 in)

Loading...

Loading...