3. Troubleshooting

63R1

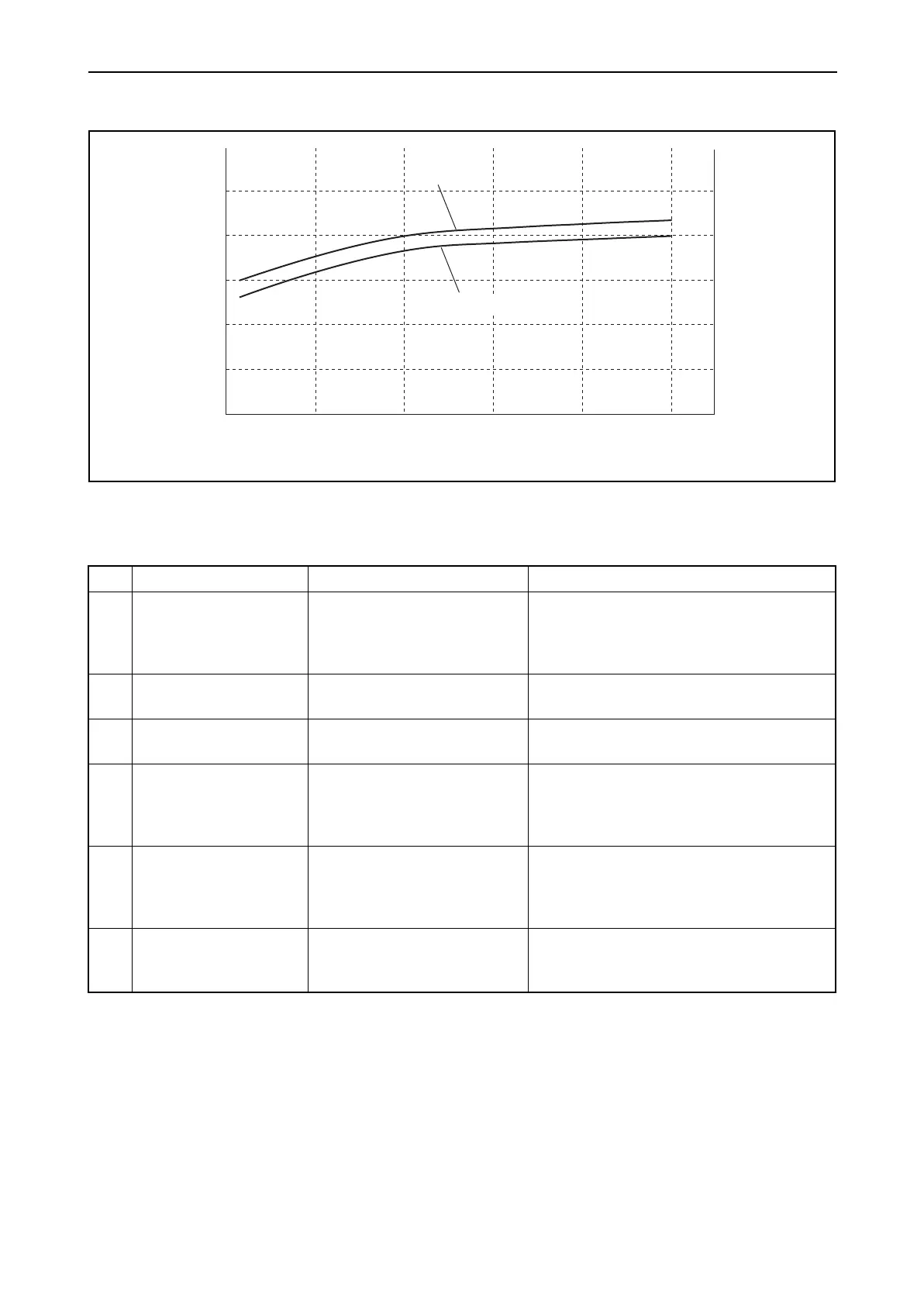

(3) Engine speed and compression pressure (for reference)

(4) Measured value and troubleshooting

When the measured compression pressure is below the limit value, inspect each part by referring to the

table below.

No. Item Cause Corrective action

1 • Air cleaner element • Clogged element

• Broken element

• Defect at element seal

portion

• Clean the element.

• Replace the element.

2 • Valve clearance • Excessive or no clearance • Adjust the valve clearance.

(See 2.2.2(5) in Chapter 2.)

3 • Valve timing • Incorrect valve clearance • Adjust the valve clearance.

(See in Chapter2.)

4 • Cylinder head

gasket

• Gas leak from gasket • Replace the gasket.

• Retighten the cylinder head bolts to the

specified torque.

(See 5.2.5 in Chapter 5.)

5 • Intake / exhaust vale

• Valve seat

• Gas leak due to worn valve

seat or foreign matter

trapping

• Sticking valve

• Lap the valve seat.

(See 5.2.2 in Chapter 5.)

• Replace the intake/exhaust valve.

6 • Piston

•Piston ring

• Cylinder

• Gas leak due to scratching

or wear

• Perform honing and use an oversized

part.

Engine speed (min

-1

)

40

35

30

25

20

3.92

3.43

2.94

2.45

1.96

(MPa)

Compression pressure (kgf/cm

2

)

3YM30

3YM20/2YM15

200 250 300 350 400

Loading...

Loading...