4. Disassembly and reassembly

72

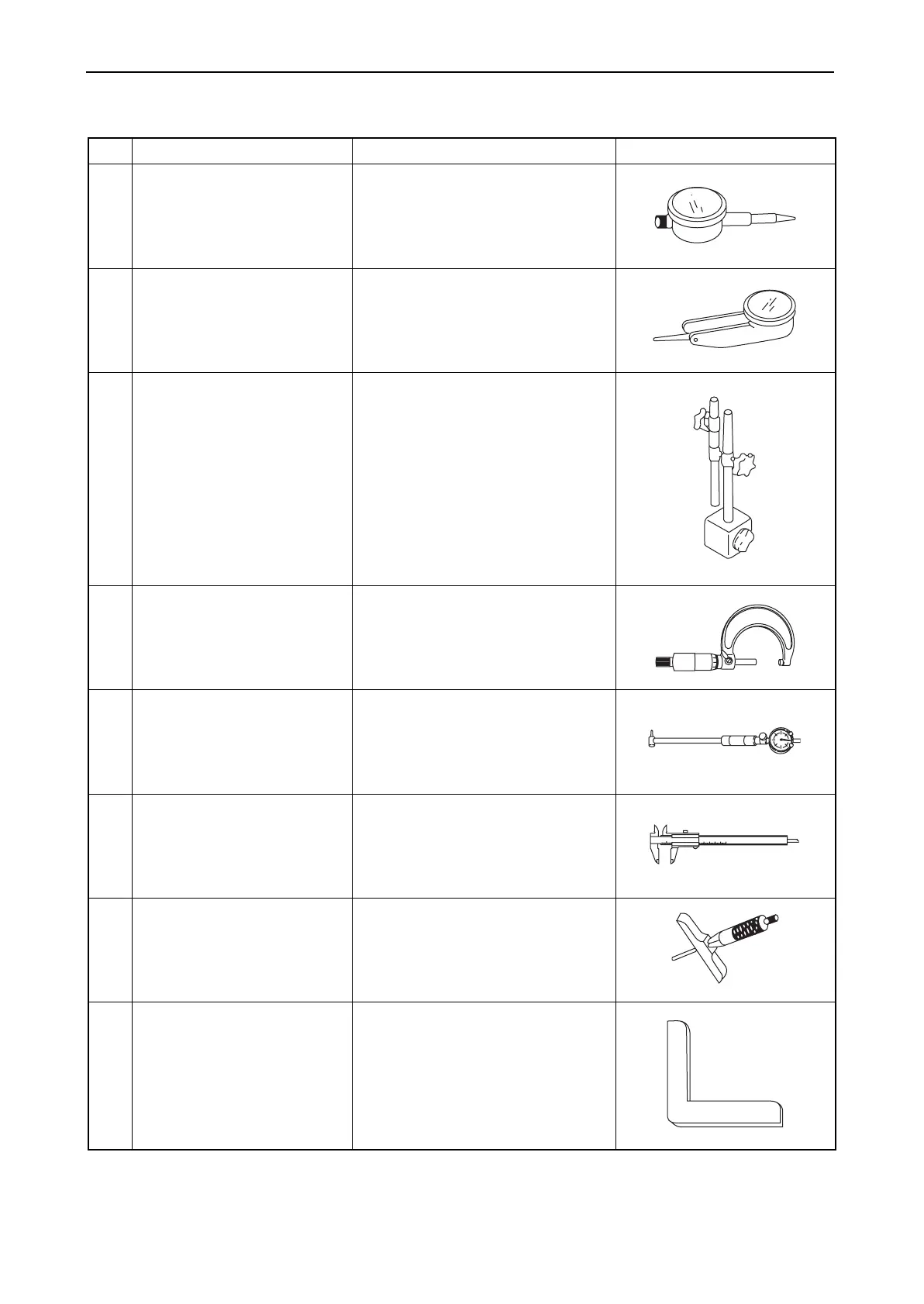

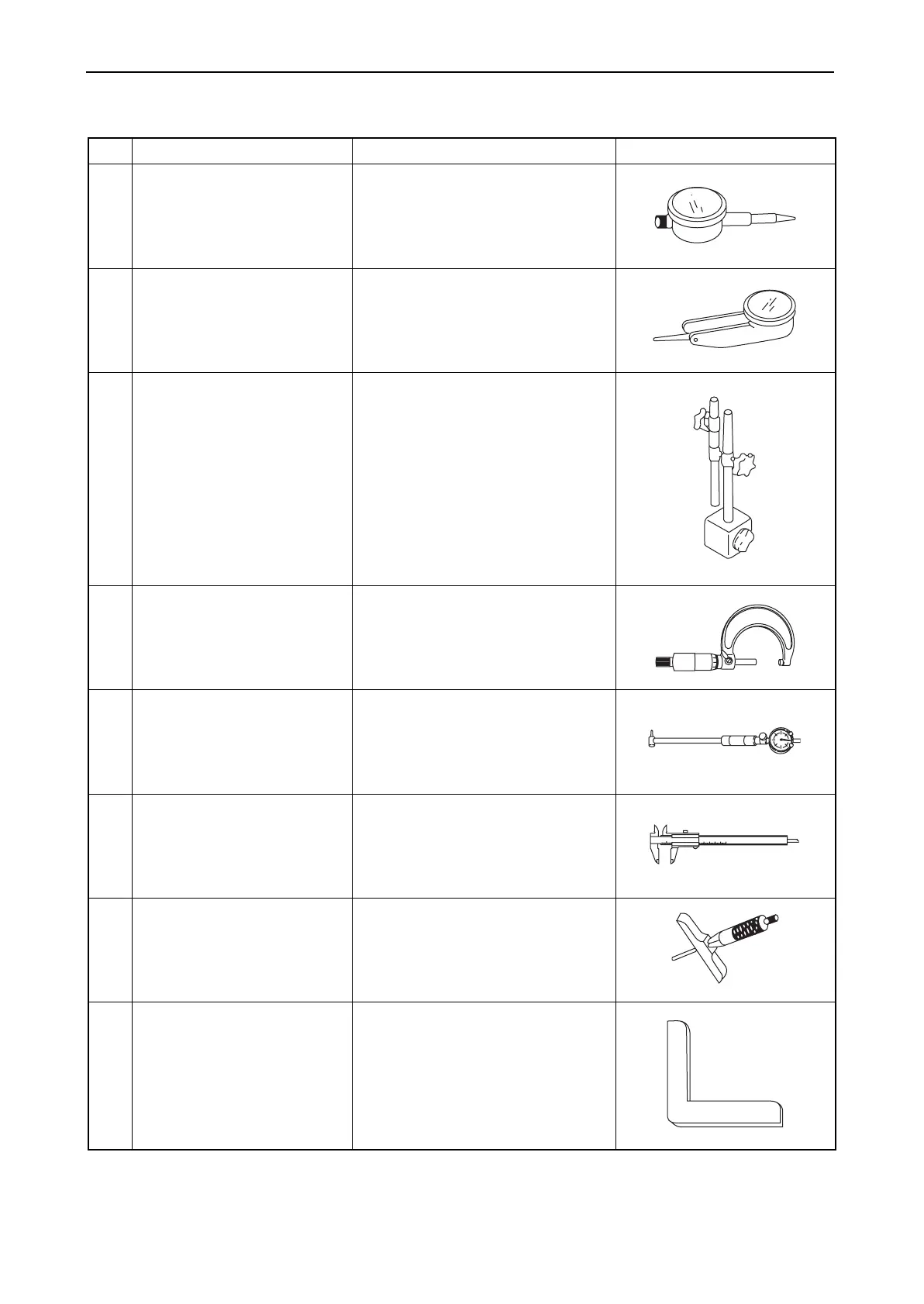

(2) Use of tools

No. Name of tool Use Illustration

1 Dial gauge Measures shaft bending, distortions

of levelness, and gaps.

2 Test indicator Measures narrow and deep places,

which cannot be measured with dial

gauge.

3 Magnetic stand Keeps the dial gauge firmly in

position, thereby permitting it to be

used at various angles.

4 Micrometer Measures the outer diameter of the

crank shaft, piston, piston pin, etc.

5 Cylinder gauge Measure the inner diameter of the

cylinder liner and rod metal.

6 Vernier calipers Measures various outer diameters,

thicknesses, and widths.

7 Depth micrometer Measures sinking of valves.

8 Square Measures distortion in position of

springs and perpendicularity of

parts.

Loading...

Loading...