140

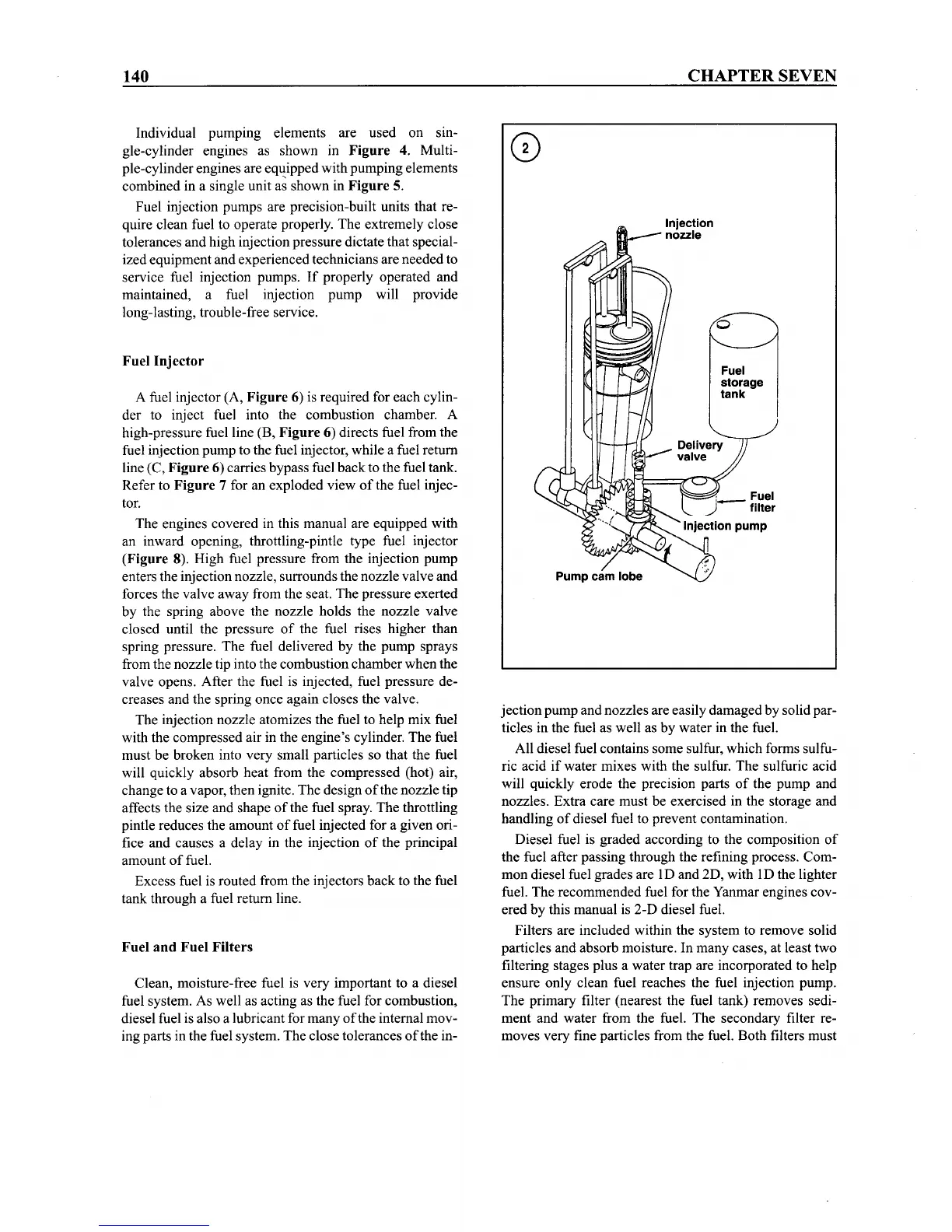

Individual pumping elements are used on sin-

gle-cylinder engines as shown in

Figure 4. Multi-

ple-cylinder engines are equipped with pumping elements

combined in a single unit

as shown in Figure 5.

Fuel injection pumps are precision-built units that re-

quire clean fuel to operate properly. The extremely close

tolerances and high injection pressure dictate that special-

ized equipment and experienced technicians are needed to

service fuel injection pumps.

If

properly operated and

maintained, a fuel injection pump will provide

long-lasting, trouble-free service.

Fuel Injector

A fuel injector (A, Figure 6) is required for each cylin-

der to inject fuel into the combustion chamber. A

high-pressure fuel line (B,

Figure 6) directs fuel from the

fuel injection pump to the fuel injector, while a fuel return

line (C,

Figure 6) carries bypass fuel back to the fuel tank.

Refer to

Figure 7 for an exploded view

of

the fuel injec-

tor.

The engines covered in this manual are equipped with

an inward opening, throttling-pintle type fuel injector

(Figure 8). High fuel pressure from the injection pump

enters the injection nozzle, surrounds the nozzle valve and

forces the valve away from the seat. The pressure exerted

by the spring above the nozzle holds the nozzle valve

closed until the pressure

of

the fuel rises higher than

spring pressure. The fuel delivered by the pump sprays

from the nozzle tip into the combustion chamber when the

valve opens. After the fuel is injected, fuel pressure de-

creases and the spring once again closes the valve.

The injection nozzle atomizes the fuel to help mix fuel

with the compressed air in the engine's cylinder. The fuel

must be broken into very small particles so that the fuel

will quickly absorb heat from the compressed (hot) air,

change to a vapor, then ignite. The design

ofthe

nozzle tip

affects the size and shape

of

the fuel spray. The throttling

pintle reduces the amount

of

fuel injected for a given ori-

fice and causes a delay in the injection

of

the principal

amount

of

fuel.

Excess fuel is routed from the injectors back to the fuel

tank through a fuel return line.

Fuel and Fuel Filters

Clean, moisture-free fuel is very important to a diesel

fuel system. As well as acting as the fuel for combustion,

diesel fuel is also a lubricant for many ofthe internal mov-

ing parts in the fuel system. The close tolerances

ofthe

in-

CHAPTER SEVEN

Injection

nozzle

Fuel

storage

tank

jection pump and nozzles are easily damaged by solid par-

ticles in the fuel as well as by water in the fuel.

All diesel fuel contains some sulfur, which forms sulfu-

ric acid if water mixes with the sulfur. The sulfuric acid

will quickly erode the precision parts

of

the pump and

nozzles. Extra care must be exercised in the storage and

handling

of

diesel fuel to prevent contamination.

Diesel fuel is graded according to the composition of

the fuel after passing through the refining process. Com-

mon diesel fuel grades are ID and 2D, with ID the lighter

fuel. The recommended fuel for the Yanmar engines cov-

ered by this manual is 2-D diesel fuel.

Filters are included within the system to remove solid

particles and absorb moisture. In many cases, at least two

filtering stages plus a water trap are incorporated to help

ensure only clean fuel reaches the fuel injection pump.

The primary filter (nearest the fuel tank) removes sedi-

ment and water from the fuel. The secondary filter re-

moves very fine particles from the fuel. Both filters must

Loading...

Loading...