144

12

Inj

ection

timin

g

shims

CHAPTER

SEVEN

5. Loosen the fitting nut (Figure 12) on the injcctor(s)

just enough to expel fuel.

6. Move the engine speed control to the full throttle posi-

tion.

7. Move the decompression lever to the ON position.

NOTE

Do not operate the starter

for

more than 30

seconds; otherwise tile starter may be dam -

aged due

to

overheating.

8. Operate the starter until air-free fuel flows from the in-

jcctorfs).

9. Tighten the injector fuel line fitting nutfs) to 20

Nom

(15 ft.-lb.).

10. Operate the starter and listen for the distinctive noise

that indicates the injector is operating.

FUEL INJECTION TIM ING

Similar to ignition timing on a gasoline engine, the fuel

must be injected at the proper time to obtain optimum

combustion,

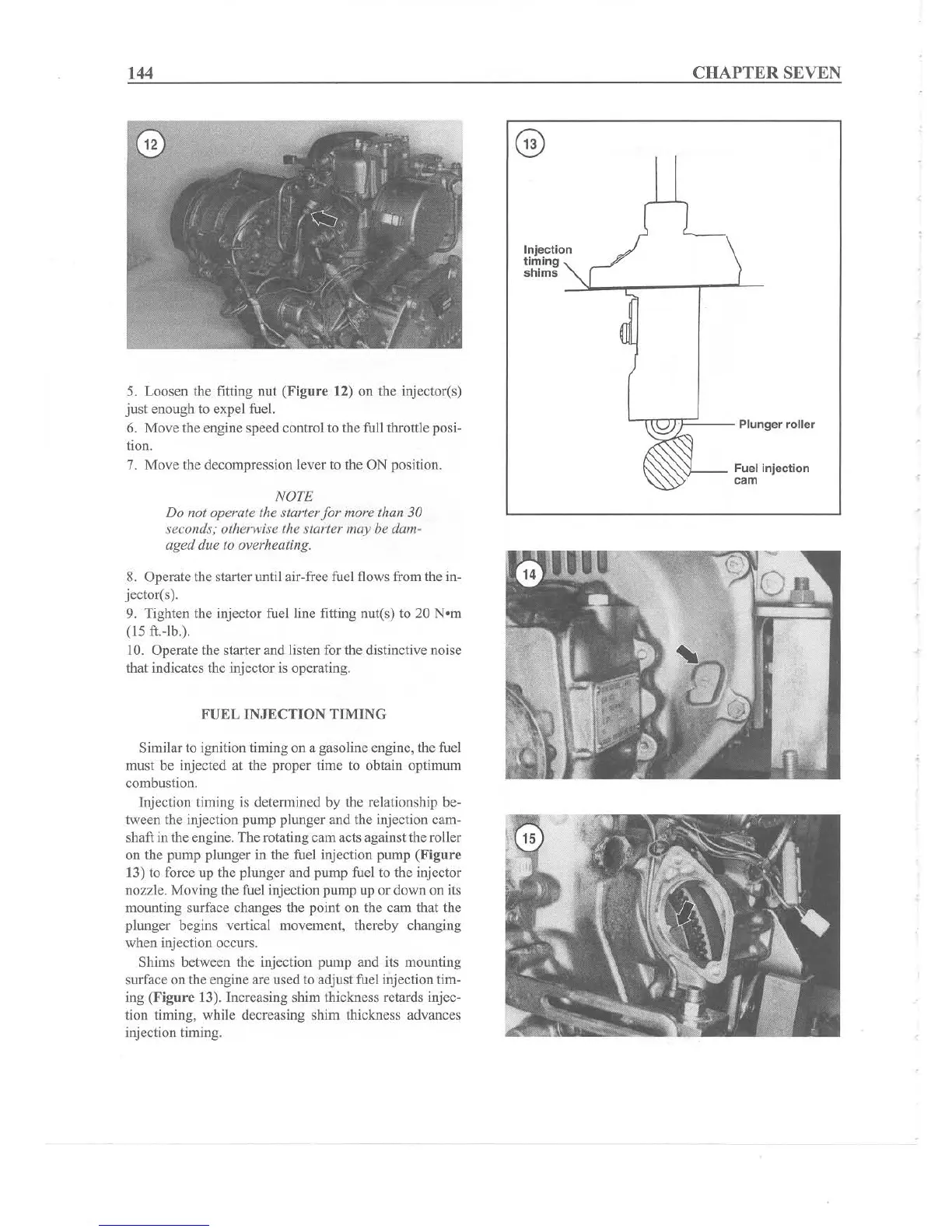

Injection timing is determined by the relationship be-

tween the injection pump plunger and the injection cam-

shaft inthe engine. The rotatingcam acts against the roller

on the pump plunger in the fuel injection pump (Figure

13) to force up the plunger and pump fuel to the injector

nozzle. Moving the fuel injection pump up or down on its

mounting surface changes the point on the cam that the

plunger begins vertical movement, thereby changing

when injection occurs.

Shims between the injection pump and its mounting

surface on the engine are used to adjust fuel injection tim-

ing (Figure 13). Increasing shim thickness retards injec-

tion timing, while decreasing shim thickness advances

injection timing.

'-\\!;Z;if:='--

- - Plunge r r

oll

er

'1-

- - Fuel

inje

cti

on

cam

Loading...

Loading...