F

UEL

IN

JECTI

ON

AND

GOVERNOR

SYSTEMS

145

.:IfiJi'r

- Spill

pipe

7

NOTE

Do not use the

starter

motor

when rotating

the crankshaft.

NOTE

On 2GM, 2GM20, 3GM, 3GM30,

3HM

and

3HM35

engines, the cylinder nearest thefly-

wheel is the

number

one

cylinder.

5. Place the speed control lever at the mid-throttle posi-

tion.

NOTE

Jfa

spiff

pipe

is

not

available or cannot he

fabricated.

observe

fuet

flow

in the open

nipple.

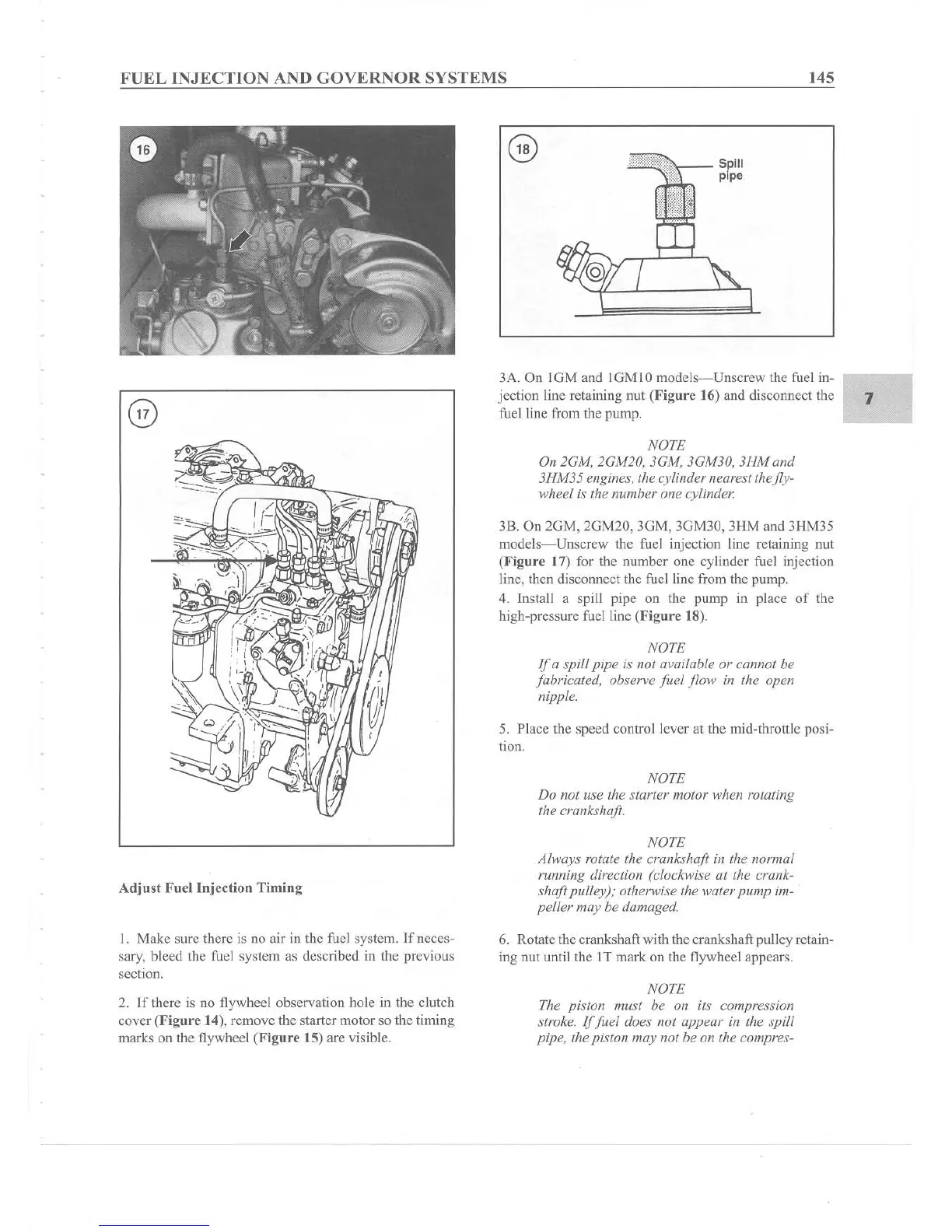

38. On

20M,

2GM20, 3GM, 3GM30, 3HM and3HM35

models-Unscrew

the fuel injection line retaining nut

(Figu re 17) for the number

one

cylinder fuel injection

line, then disconnect the fuel line from the pump.

4. Install a spill pipe on the pump in place

of

the

high-pressure fuel line (Fig

ure

18).

3A. On IGM and IGMIO models

-Unscrew

the fuel in-

.----"

jcction line retaining nut (Figure 16) and disconnect the

fuel line from the pump.

Adjust Fucl lnjcction Timing

NOTE

Always

rotate the crankshaft in the

normal

running direction (clockwise at the crank-

shaft

pulley); otherwise the water

pump

im-

peller

may

be damaged.

1. Make sure there is no air in the fuel system.

If

neces-

sary, bleed the fuel system as described in the previous

section.

6. Rotate the crankshaft with the crankshaftpulley retain-

ing nut until the IT mark on the flywheel appears.

2. If there is no flywheel observation hole in the clutch

cover

(Figure

14), remove the starter motor so the timing

marks on the flywheel (Fi

gure

15) are visible.

NOTE

The piston

must

be 011 its

comp

ression

stroke.

If

fuel

does not

appear

in the spill

pipe

, the piston

may

1I0the on the compres-

Loading...

Loading...