146

sian stroke. Rotate the crankshaft one full

turn.

7. Slowly rotate the crankshaft while observing the fuel

in the fuel nipple on the injection pump and the timing

marks on the flywheel.

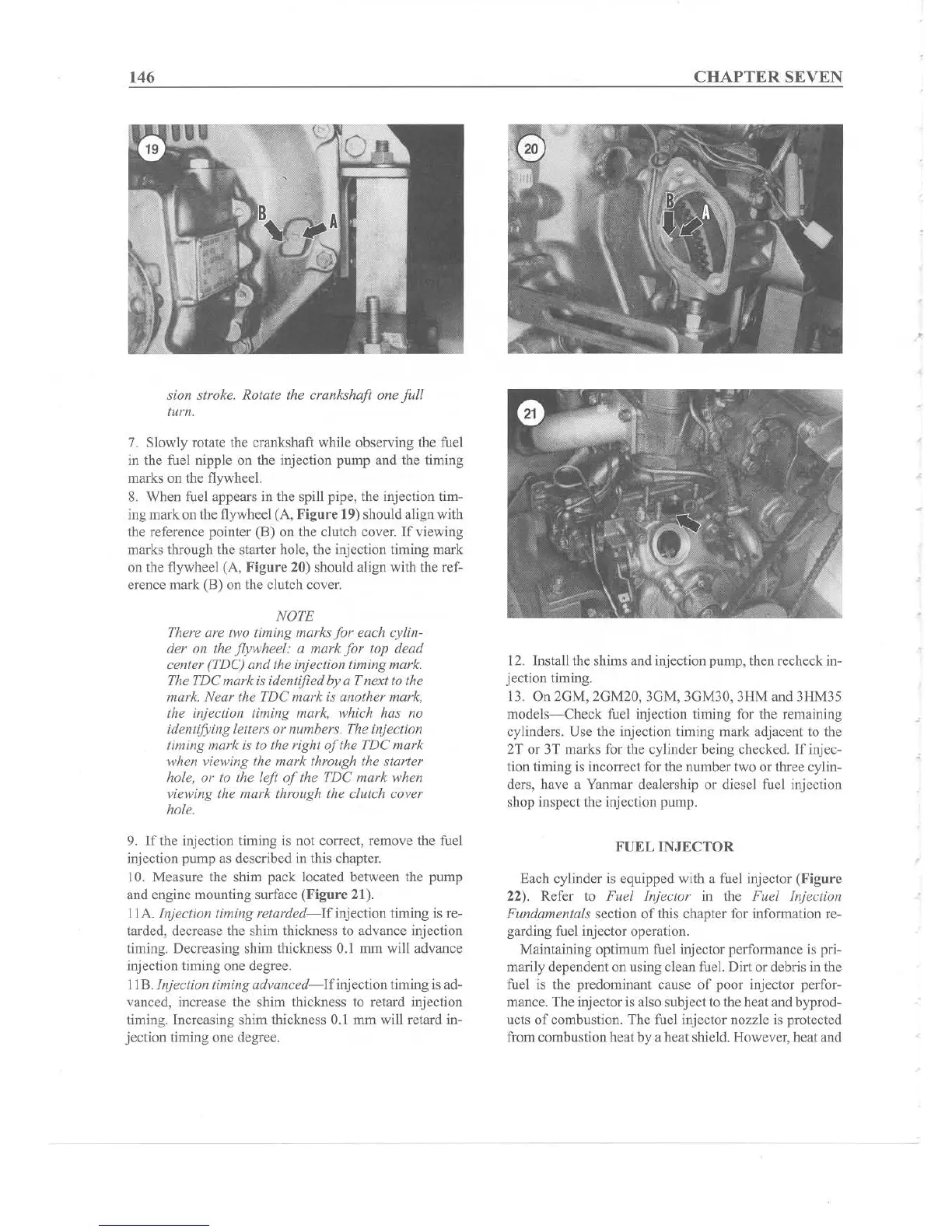

8. When fuel appears in the spill pipe, the injection tim-

ing mark on the flywheel (A. Fig

ur

e 19) should align with

the reference pointer (B) on the clutch cover. If viewing

marks through the starter hole, the injection timing mark

on the flywheel (A, Fig

ure

20) should align with the ref-

erence mark (B) on the clutch cover.

NOTE

There are two timing marks

[or

each cylin-

der 011 the flywheel: a

mark

for

top

dead

center (TDC)

and

the injection timing mark.

The TDC mark

is identified by a T next to the

mark. Near the TDC mark is another mark,

the injection liming mark, which has no

identifying letters or numbers. The injection

timing mark

is to the right

of

the TDC mark

when viewing the mark through the starter

hole, or to the leli

of

the TDC mark when

viewing the mark through the clutch cover

hole.

9. If the injection timing is not correct, remove the fuel

injection pump as described in this chapte r.

I

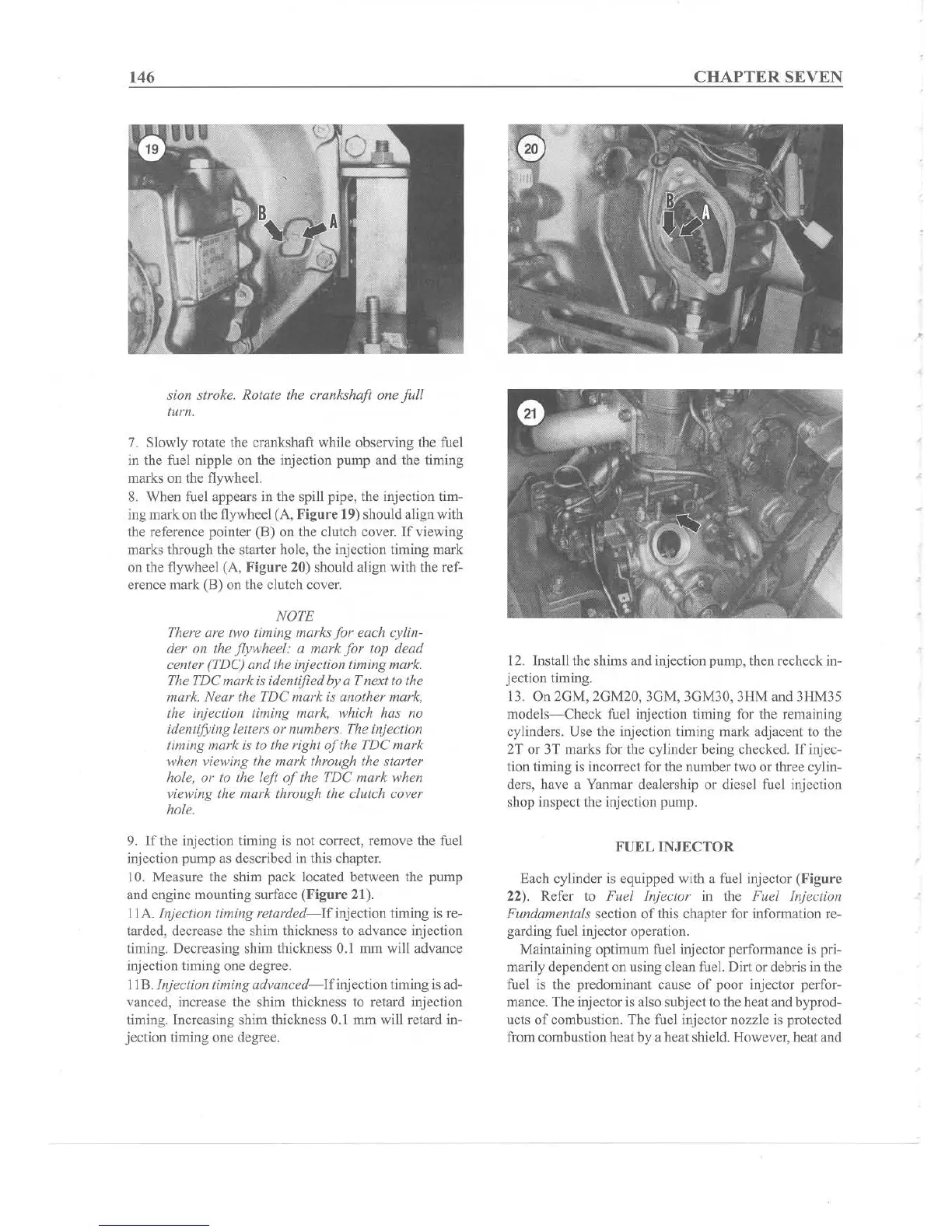

D.

Measure the shim pack located between the pump

and engine mounting surface (

Figure

21).

liA

. Injection timing retarded

-If

injection timing is re-

tarded, decrease the shim thickness to advance injection

timing. Decreasing shim thickness D.I mm will advance

injection timing one degree.

11

B. Injection timing advanced- If injection timing is ad-

vanced, increase the shim thickness to retard injection

timing . Increasing shim thickness 0.1 mm will retard in-

jection timing one degree.

C

HAPTER

SEVEN

12, Install the shims and injection pump, then recheck in-

jection timing.

13. On 2GM, 2GM

2D,

3GM, 3GM3

D,

3HM and 3HM35

models-s-Check fuel injection timing for the remaining

cylinders. Use the injection timing mark adjacent to the

2T or 3T marks for the cylinder being checked. If injec-

tion timing is incorrect for the number two or three cylin-

ders, have a Yanmar dealership or diesel fuel injection

shop inspect the injection pump.

FUEL

[

VJECT

OR

Each cylinder is equipped with a fuel injector (f igure

22). Refer to Fuel Inj ector in the Fuel Injection

Fundamentals

section

of

this chapter for information re-

garding fuel injector operation.

Maintaining optimum fuel injector perfonnanec is pri-

marily dependent on using clean fuel. Din or debris in the

fuel is the predominant cause of poor injector perfor-

mance . The injector is also subject to the heat and byprod-

ucts of combu stion. The fuel injector nozzle is protected

from combustion heat by a heat shield. However, heat and

•

Loading...

Loading...