170

Sea

water

pum

p drive b

el

t replacement

(except I

GJI

and IG.UI Oengines)

Replace the seawater drive belt as follows:

I.

Loosen the alternator bracket and pivot bolts (Figure

17, typica l).

2. Move the alternator toward the engine and slip the

belt

off

the crankshaft and alternator pulleys, and if equipped

with freshwater cooling, the circulating water pump pul-

Icy.

3. Loosen the seawater pump bracket and pivot bolts

(Fi

J::

ure

18, typical),

4. Move the seawater pump toward the engine and slip

the belt off the crank shaft and pump pulleys.

5. Install a new belt over the pulleys.

6. Move the seawater pump away from the engine and

adjust the belt tension as described in Chapter Three.

7. Install the alternator drive bell onto the crankshaft and

alternator pulleys. and if equipped with freshwater cool-

ing. the circulating water pump pulley.

8. Move the alternator away from the engine and ad

ju

st

the belt tension as described in Chapter Three.

SEA

WATE R P

UMP

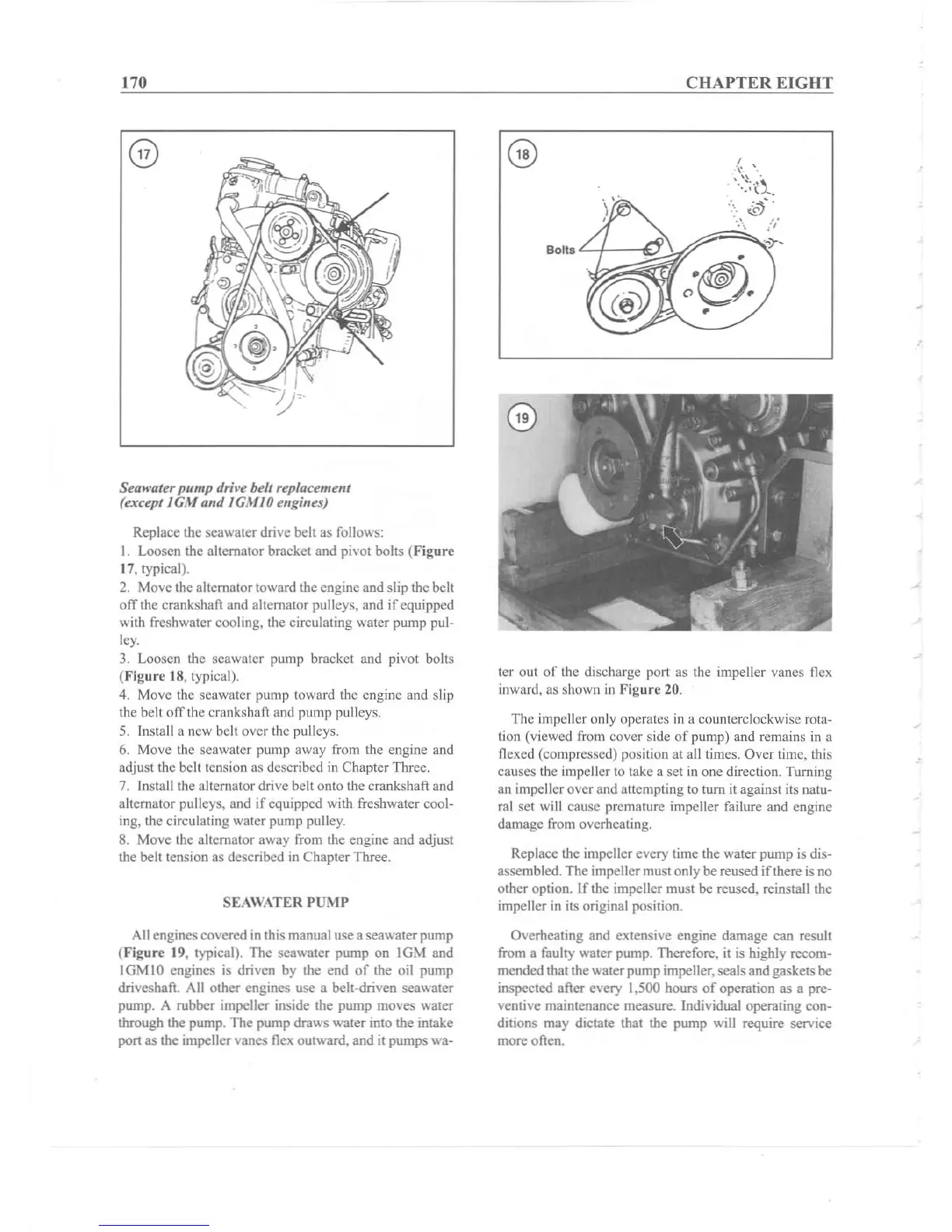

All engines covered in this manual use a seawater pump

(Ftgure 19. typical). The seawater pump on

IGM

and

IGMIO engines is driven by the end

of

the oil pump

drives haft. All other eng ines use a belt-driven seawater

pump. A rubber impeller inside the pump moves water

through the pump. The pump draws water into the intake

port as the impeller vanes flex outward. and it pumps wa-

CIIAPTER EIG

IIT

-{.

'.

-.

'

~

.

,

ito

··'l

.J..

Bolts

L-

+--

-~

D

tcr out of the discharge port as the impeller vanes flex

inward . as shown in

Fi

gur

e 20.

The impeller only operates in a counterclockwise rota-

tion (viewed from cover side

of

pump) and remains in a

flexed (compressed) position at all times.

Over

time, this

causes the impeller to take a set in one direction . Turning

an impeller over and attempting to tum it aga inst its natu-

ral set will cause premature impeller failure and engine

damage from overheat ing.

Replace the impeller every time the water pump is dis-

assemb led. The impeller must only be reused if there is no

other option. If the impeller must be reused . reinstall the

impeller in its origina l position.

Overheating and extensive engine dama ge can result

from a faulty water pump. Therefore, it is highly recom-

mended that the waterpump impeller, seals and gaskets be

inspected after every 1,500 hours

of

operation as a pre-

ventive maintenance meas ure. Individual operating con-

ditions may dictate that the pump will require service

more often.

Loading...

Loading...