TRANSMISSION-KBW SERIES

9. Referto Steps 7 and 8

and

disassemble the clutch com-

ponents on the reverse gear.

10.

Lay

the shift ring and pressure plate assembly flat.

11. Remove the pressure plate return springs (24,

Figure

3), then lift

off

the top pressure plate (17)

and

remove the

steel balls (18).

12. Liftthe shiftring (25,

Figure3)

and

driving plate(22)

off

the bottom pressure plate and remove the three re-

maining balls.

13. Slip the shift ring (25,

Figure 3)

off

the driving plate

(22).

14. Remove the alignment pins (21,

Figure 3)

and

detent

pins (20) with springs (19) from the driving plate (22).

Inspection

I.

Check

the

gear

teeth for excessive wear, corrosion or

rust and mechanical damage.

Check

the teeth for galling,

chips, cracks, missing pieces, distortion or discoloration

from overheating.

Check

the splines for excessive

wear

or

damage. Replace the gears

if

damaged.

221

2. Inspect the output shaft bearings

and

seal surfaces for

excessive wear, grooving, metal transfer and discolor-

ation from overheating.

3. Inspect the key and output shaft keyway for damage.

NOTE

Shims behind the outer bearing race in the

mountingflange determine bearingpreload

for

the outputshaft bearings. Save the shims

and

reinstall them

if

reusing the original

parts.

4. Inspect the input shaft bearing outer races in the trans-

mission case and mounting flange.

If

either race is dam-

aged

or excessively worn, remove it using a suitable

puller.

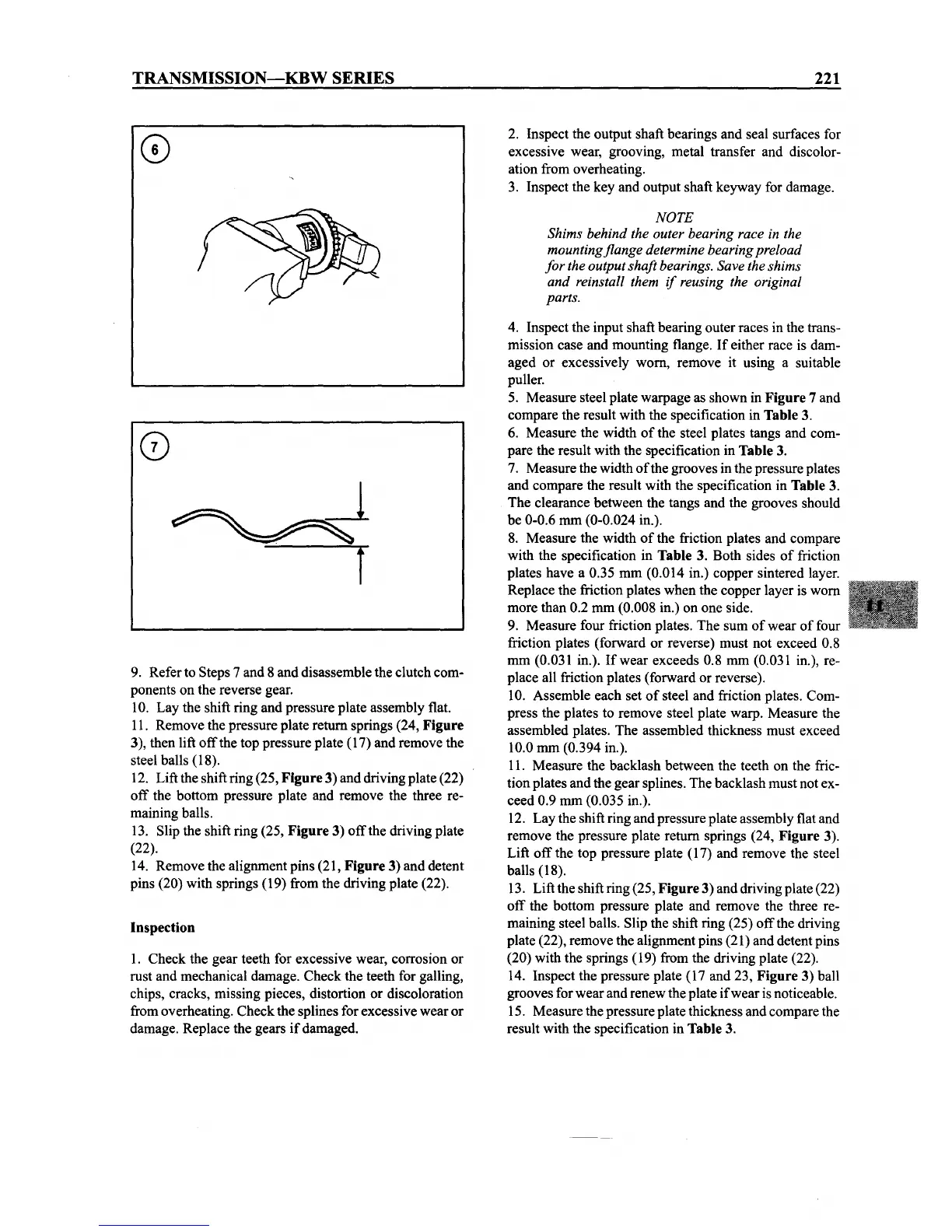

5. Measure steel plate warpage as shown in

Figure 7 and

compare the result with the specification in

Table3.

6. Measure the width

of

the steel plates tangs

and

com-

pare the result with the specification in

Table3.

7. Measure the width

of

the grooves in the pressure plates

and

compare the result with the specification in Table3.

The

clearance between the tangs and the grooves should

be 0-0.6 rom (0-0.024 in.).

8. Measure the width

of

the friction plates and compare

with the specification in

Table 3. Both sides

of

friction

plates have a 0.35

mm

(0.014 in.) copper sintered layer.

Replace the friction plates

when

the copper layer is

worn

more than 0.2 rom (0.008 in.) on one side.

9. Measure four friction plates.

The

sum

of

wear

of

four

friction plates (forward or reverse)

must

not exceed 0.8

mm (0.031 in.).

If

wear

exceeds 0.8 rom (0.031 in.), re-

place all friction plates (forward or reverse).

10. Assemble each set

of

steel and friction plates. Com-

press the plates to remove steel plate warp. Measure the

assembled plates.

The

assembled thickness

must

exceed

10.0

mm

(0.394 in.).

11. Measure the backlash between the teeth on the fric-

tionplates

and

the

gear

splines.

The

backlash

must

not ex-

ceed

0.9 mm (0.035 in.).

12.

Lay

the shift ring and pressure plate assembly flat and

remove the pressure plate return springs (24,

Figure 3).

Lift

off

the top pressure plate (17) and remove the steel

balls (18).

13. Liftthe shiftring (25,

Figure 3) and driving plate (22)

off

the bottom pressure plate and remove the three re-

maining steel balls. Slip the shift ring (25)

off

the driving

plate (22), remove the alignment pins (21) and detent pins

(20) with the springs (19) from the driving plate (22).

14. Inspect the pressure plate (17 and 23,

Figure 3) ball

grooves for

wear

and renew the plate

if

wear

is noticeable.

15. Measure the pressureplate thickness and compare the

result with the specification in

Table3.

Loading...

Loading...