OPERATION, LUBRICATION, MAINTENANCE AND TUNE-UP

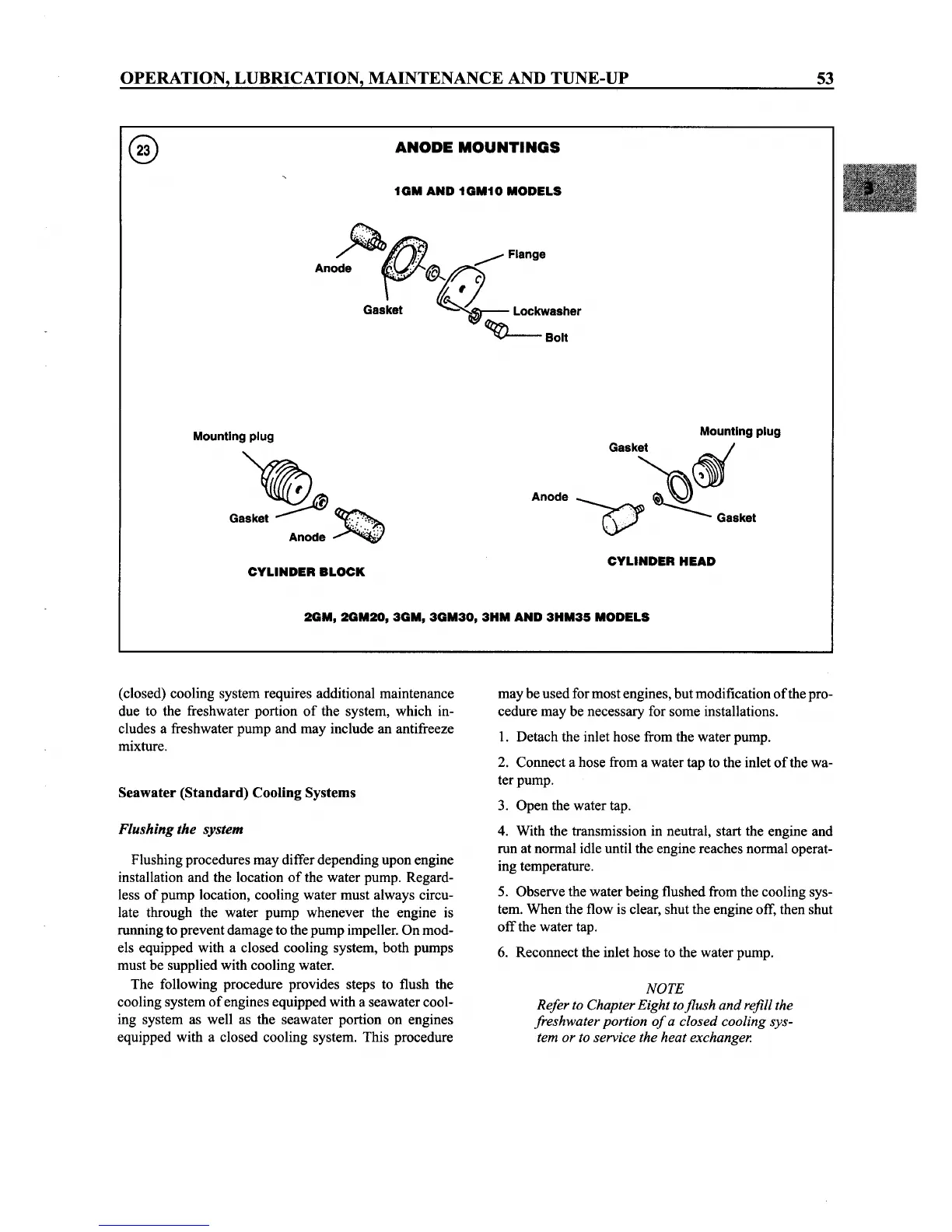

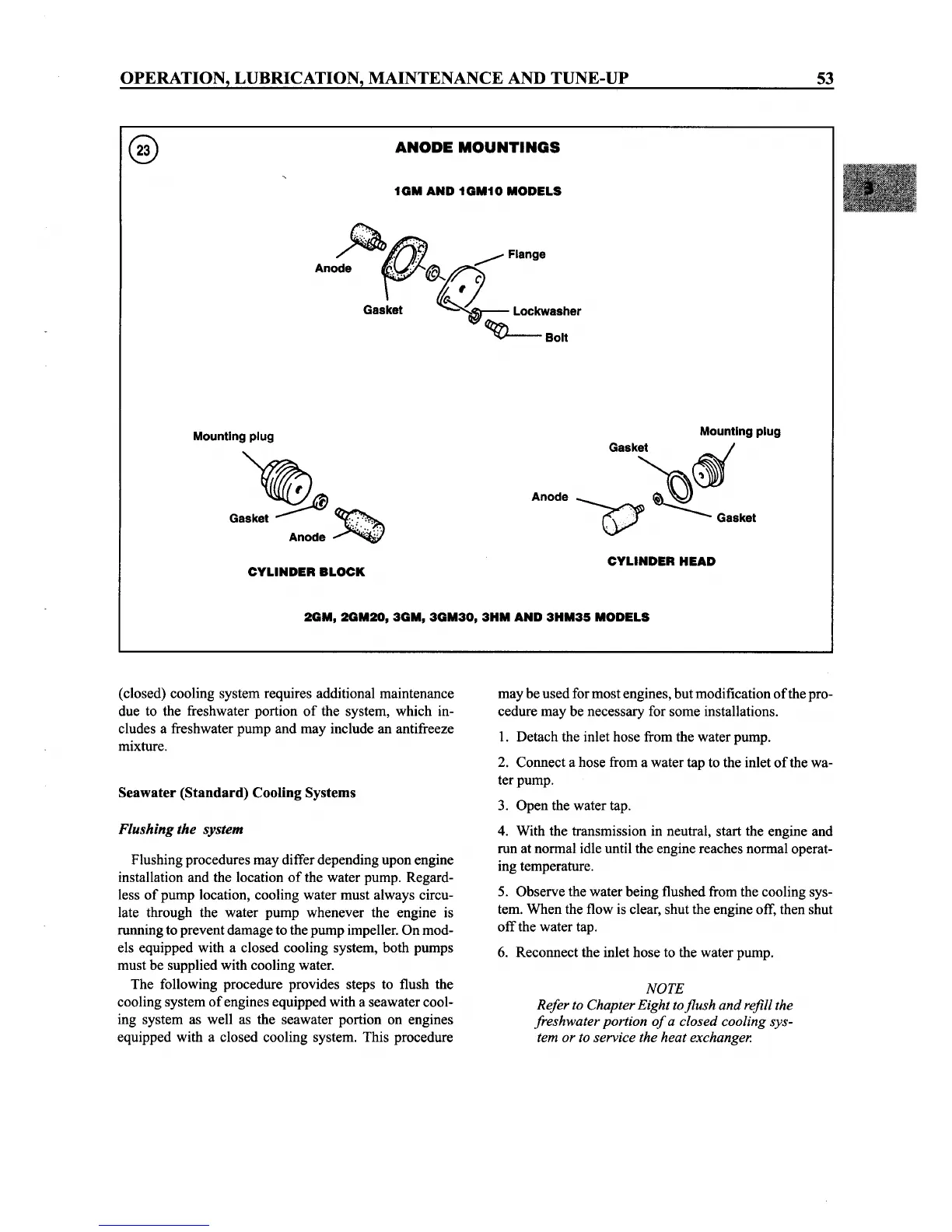

ANODE

MOUNTINGS

1GM

AND

1GM10

MODELS

~hl

..---F'

....

Anode

F-tRQ

Gasket

~

Lockwasher

~Bolt

53

Mounting plug

~<

GaSket~~

Anode~

CYLINDER

BLOCK

Anode

Mounting plug

Gas~~

~~GaSket

CYLINDER

HEAD

2GM,

2GM20,

3GM,

3GM30,

3HM

AND

3HM35

MODELS

(closed) cooling system requires additional maintenance

due to the freshwater portion

of

the system, which in-

cludes a freshwater pump and may include an antifreeze

mixture.

Seawater (Standard) Cooling Systems

Flushing the system

Flushing procedures may differ depending upon engine

installation and the location

of

the water pump. Regard-

less

of

pump location, cooling water must always circu-

late through the water pump whenever the engine is

running to prevent damage to the pump impeller. On mod-

els equipped with a closed cooling system, both pumps

must be supplied with cooling water.

The following procedure provides steps to flush the

cooling system

of

engines equipped with a seawater cool-

ing system as well as the seawater portion on engines

equipped with a closed cooling system. This procedure

may be used formost engines, but modification

of

the pro-

cedure may be necessary for some installations.

1. Detach the inlet hose from the water pump.

2. Connect a hose from a water tap to the inlet

of

the wa-

terpump.

3. Open the water tap.

4. With the transmission in neutral, start the engine and

run at normal idle until the engine reaches normal operat-

ing temperature.

5. Observe the water being flushed from the cooling sys-

tem. When the flow is clear, shut the engine off, then shut

off

the water tap.

6. Reconnect the inlet hose to the water pump.

NOTE

Refer to Chapter Eight toflush and refill the

freshwater portion

of

a closed cooling sys-

tem or to service the heat exchanger.

Loading...

Loading...