54

Freshwater

(Closed) Cooling Systems

Inspection

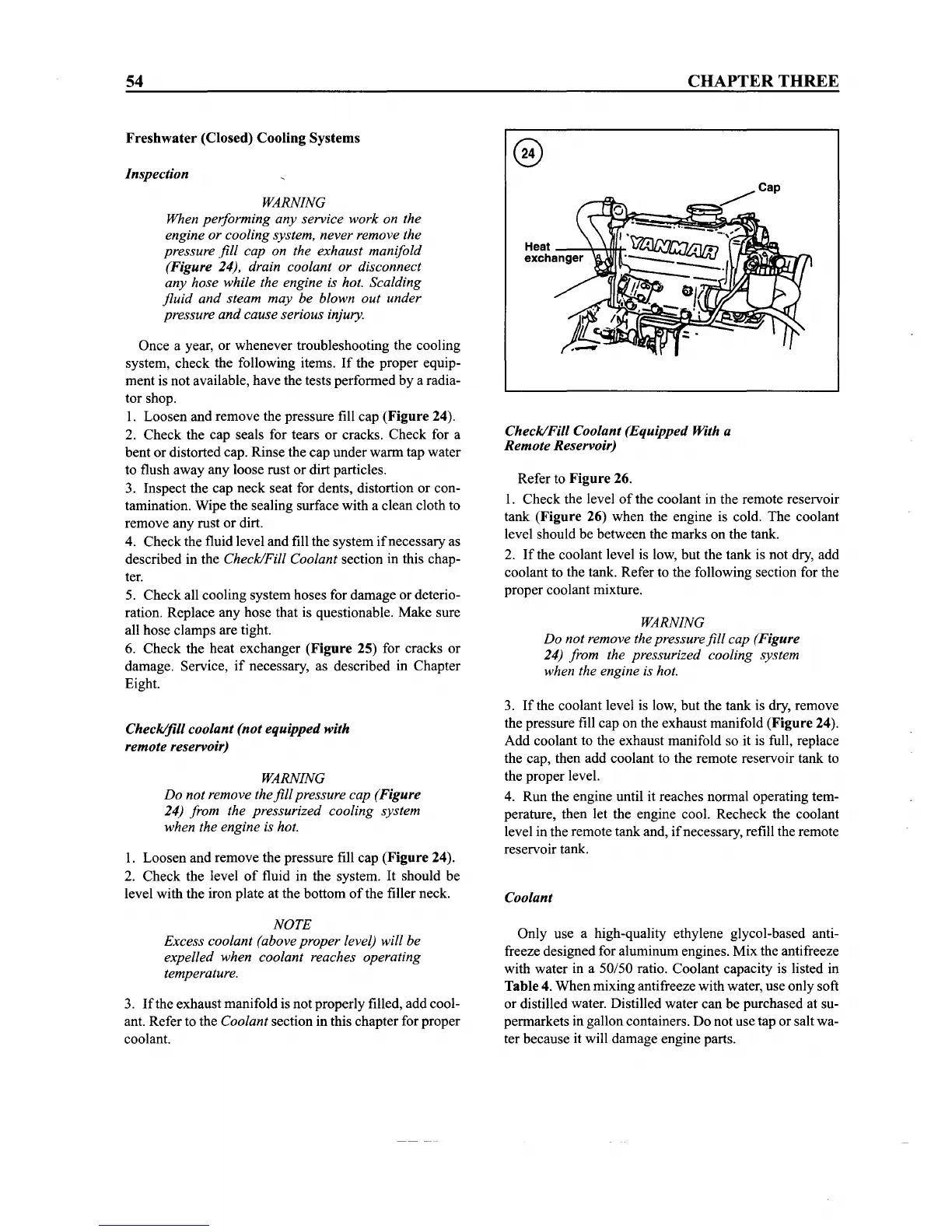

WARNING

When performing any service work on the

engine or cooling system, never remove the

pressure

jill

cap on the exhaust manifold

(Figure

24), drain coolant or disconnect

any hose while the engine

is hot. Scalding

fluid and steam may be blown out under

pressure and cause serious injury.

Once a year, or whenever troubleshooting the cooling

system, check the following items.

If

the proper equip-

ment is not available, have the tests performed by a radia-

tor shop.

1. Loosen and remove the pressure fill cap

(Figure

24).

2. Check the cap seals for tears or cracks. Check for a

bent or distorted cap. Rinse the cap underwarm tap water

to flush away any loose rust or dirt particles.

3. Inspect the cap neck seat for dents, distortion or con-

tamination. Wipe the sealing surface with a clean cloth to

remove any rust or dirt.

4. Check the fluid level and fill the system

if

necessary as

described in the

Check/Fill Coolant section in this chap-

ter.

5. Check all cooling system hoses for damage or deterio-

ration. Replace any hose that is questionable. Make sure

all hose clamps are tight.

6. Check the heat exchanger

(Figure

25) for cracks or

damage. Service,

if

necessary, as described in Chapter

Eight.

Check/fill coolant (not equipped with

remote reservoir)

WARNING

Do not remove the

jill

pressure cap (Figure

24) from the pressurized cooling system

when the engine

is hot.

1. Loosen and remove the pressure fill cap

(Figure

24).

2. Check the level

of

fluid in the system.

It

should be

level with the iron plate at the bottom

of

the filler neck.

NOTE

Excess coolant (above proper level) will be

expelled when coolant reaches operating

temperature.

3.

Ifthe

exhaust manifold is not properly filled, add cool-

ant. Refer to the

Coolant section in this chapter for proper

coolant.

CHAPTER THREE

Check/Fill Coolant (Equipped With a

Remote Reservoir)

Refer to

Figure

26.

1. Check the level

of

the coolant in the remote reservoir

tank

(Figure

26) when the engine is cold. The coolant

level should be between the marks on the tank.

2.

If

the coolant level is low, but the tank is not dry, add

coolant to the tank. Refer to the following section for the

proper coolant mixture.

WARNING

Do not remove the pressure jill cap (Figure

24) from the pressurized cooling system

when the engine

is hot.

3.

If

the coolant level is low, but the tank is dry, remove

the pressure fill cap on the exhaust manifold

(Figure

24).

Add coolant to the exhaust manifold so it is full, replace

the cap, then add coolant to the remote reservoir tank to

the proper level.

4. Run the engine until it reaches normal operating tem-

perature, then let the engine cool. Recheck the coolant

level in the remote tank and,

if

necessary, refill the remote

reservoir tank.

Coolant

Only use a high-quality ethylene glycol-based anti-

freeze designed for aluminum engines. Mix the antifreeze

with water in a

50/50 ratio. Coolant capacity is listed in

Table 4. Whenmixing antifreeze with water, use only soft

or distilled water. Distilled water can be purchased at su-

permarkets in gallon containers. Do not use tap or salt wa-

ter because it will damage engine parts.

Loading...

Loading...