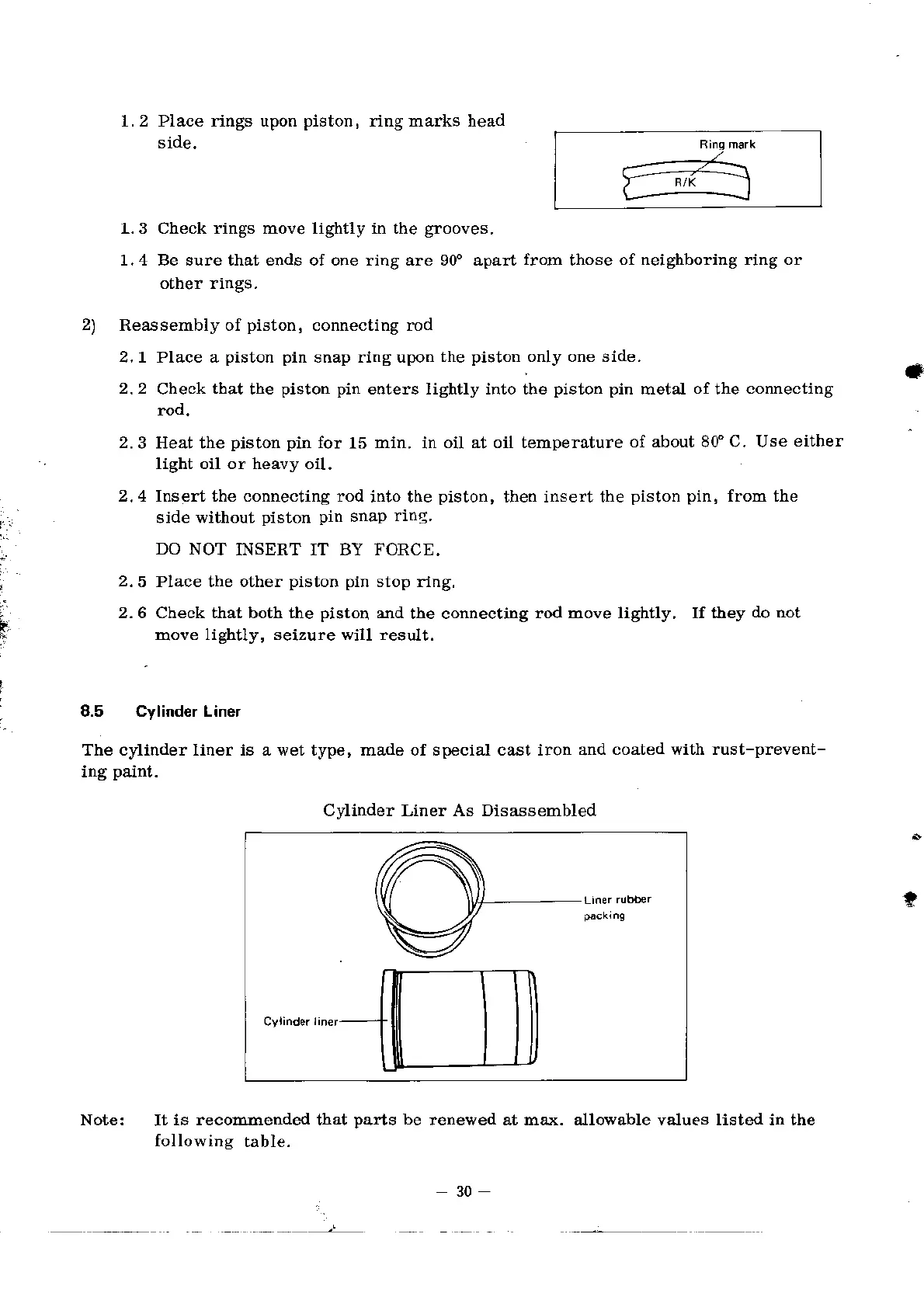

1.2 Place rings upon

piston,

ring marks head

side.

1.3 Check rings move lightly in the

grooves.

1.4 Be sure that ends oJ one ring are 9f apart

from

those

of neighboring ring or

other rings.

2)

Reassembly of

piston,

connecting rod

2,I Place a

piston pin

snap ring upon

the

piston

only one side.

2.2

Check

that

the

piston pin

enters lightly into tbe

piston pin

meta.l

of

the

connecting

rod'

2.3

Heat the

piston pin

for

15

min.

in

oil at oil temperature

of about 8f C. Use

either

light oil or heavy oil.

2.4 Insert the connecting rod

into the

piston,

then insert the

piston

pin,

from the

ll

ide without

piston

pin

snap

ring

DO NOT

INSERT IT BY FORCE,

,

2.5

Place the other

piston pin

stop ring.

,

2. A Check *Iat both the

pistoq

and

the connectiDg

rod move lightly, If they

do not

I

lr)ove lightly, seizure will result.

I

_

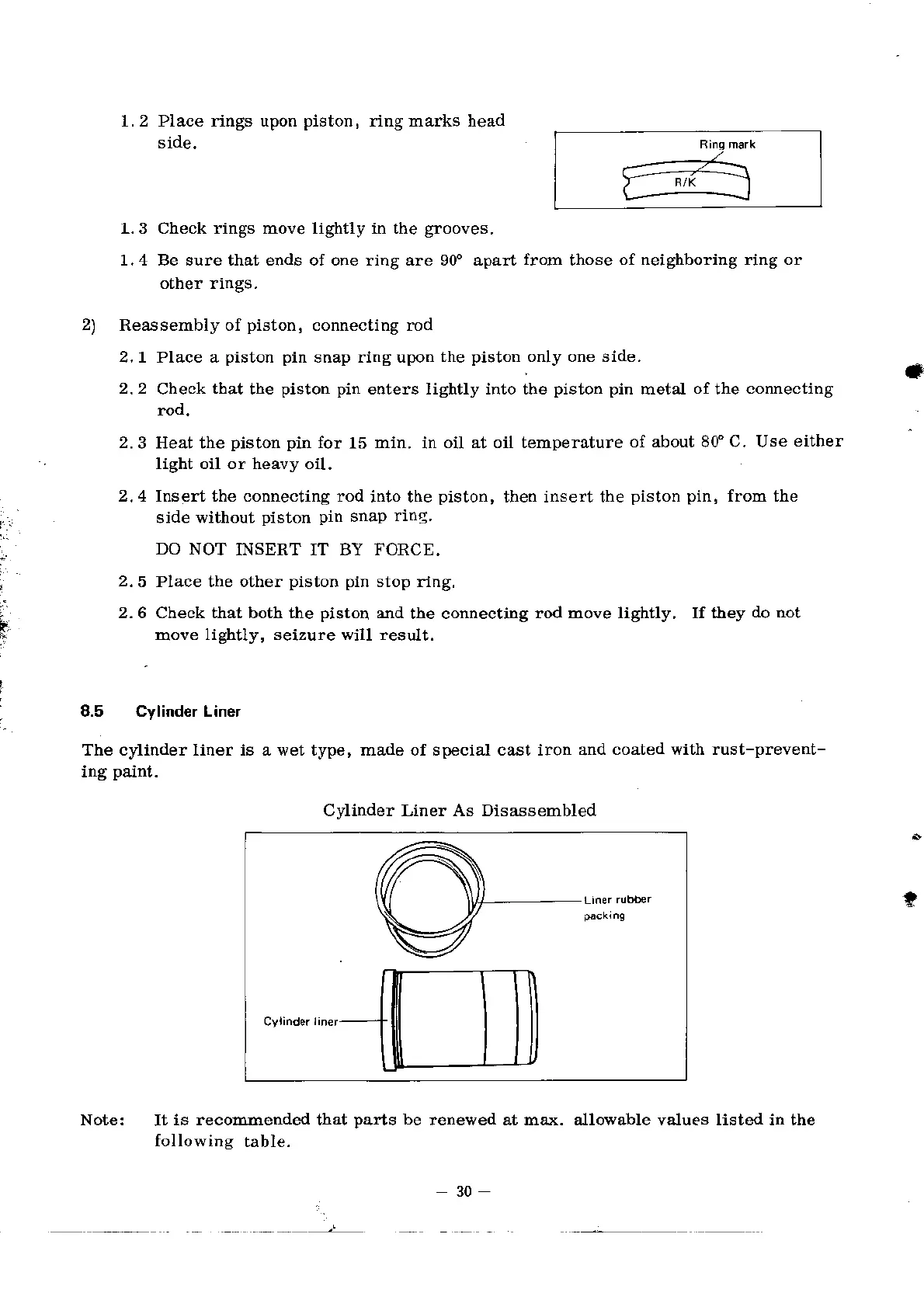

8.5 Cylinder Liner

The cylinder liner is a wet type, made of special cast iron and

coated with rust-prevent-

ing

paint.

Cylinder Liner As Disassembled

*

?

Note:

It

is recoEmended that

parts

be

renewed at max. allowable values listed in the

followine

table.

30

Loading...

Loading...