3.

(7)

(a)

(b)

(8)

(9)

CABINET CONSTRUCTION DESIGN

(Cent’d)

To prevent malfunction due to noise, mount the units more

than 100 mm from cables feeding 90 VDC or greater, AC

power lines, and other components. The following

precautions should be complied with during wiring:

Separate AC and DC cables.

Separate the primary and secondary sides of transformers, line

filters, etc.

The front panels of the units that are exposed to the cabinet

surfaces, such as the CNC operator’s panel, tape reader, and

PO unit should be of a dustproof type. However, do not install

them in locations where cutting fluid may directly splash on

them. Be sure to seal completely around the mounting

sections.

Mount the units so as to allow easy checking, removal and

reinstalling during maintenance work.

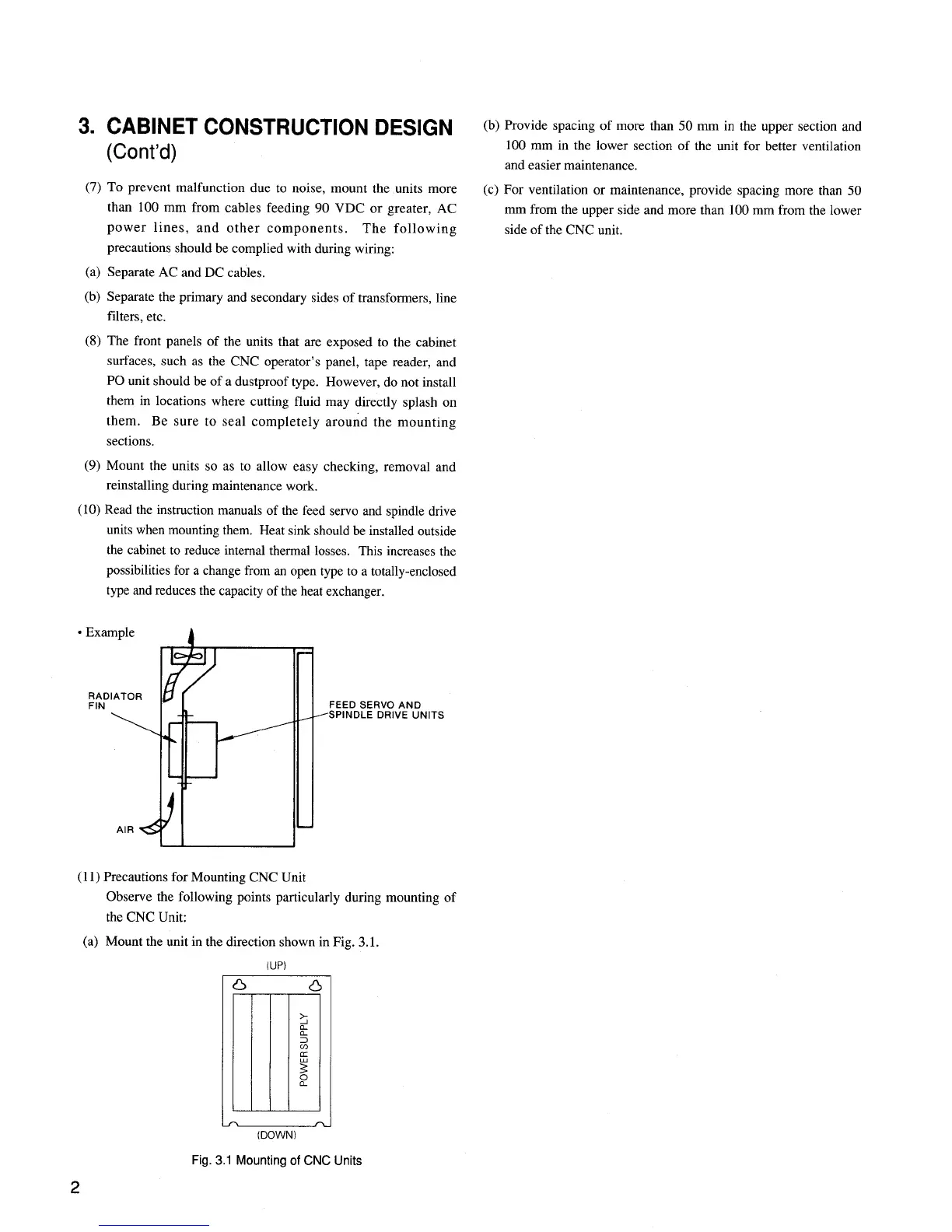

(10) Read the instruction manuals of the feed servo and spindle drive

units when mounting them. Heat sink should be installed outside

the cabinet to reduce internal thermal losses. This increases the

possibilities for a change from an open type to a totally-enclosed

type and reduces the capacity of the heat exchanger.

● Example

4

RADIATOR

FIN

3-

* \

J-

AIR

FEED SERVO AND

-+ PINDLE DRIVE UNITS

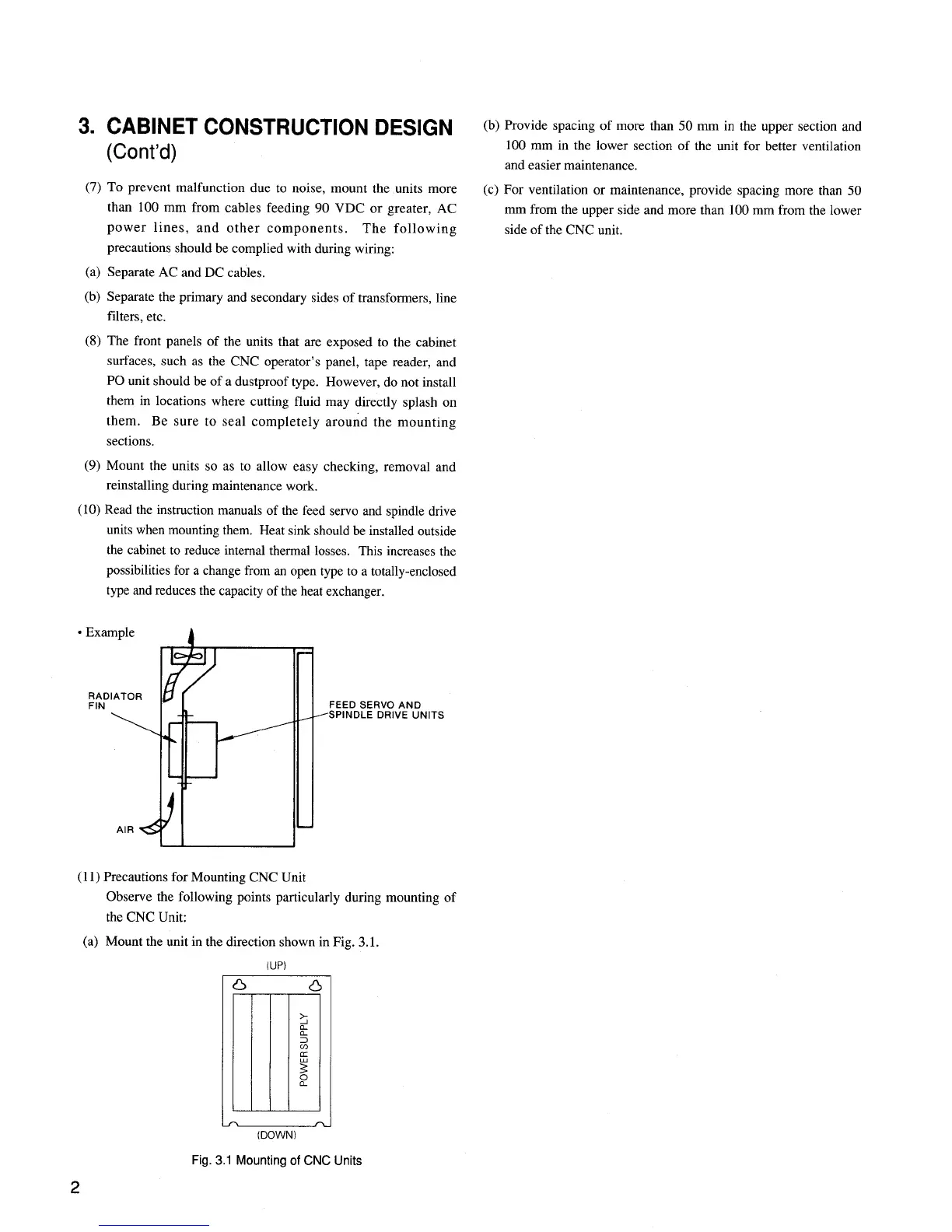

(11) Precautions for Mounting CNC Unit

Observe the following points particularly during mounting of

the CNC Unit:

(a) Mount the unit in the direction shown in Fig. 3.1.

n

n

(DOWN)

(b) Provide spacing of more than 50 mm in the upper section and

100 mm in the lower section of the unit for better ventilation

and easier maintenance.

(c) For ventilation or maintenance, provide spacing more than 50

mm from the upper side and more than 100 mm from the lower

side of the CNC unit.

(UP)

Fig. 3.1 Mounting of CNC Units

2

Loading...

Loading...