Display deviating

Quick Reference Instruction Manual

Troubleshooting

IM01U10A00-00EN-R, 2nd edition, 2017-08-29

53 / 54

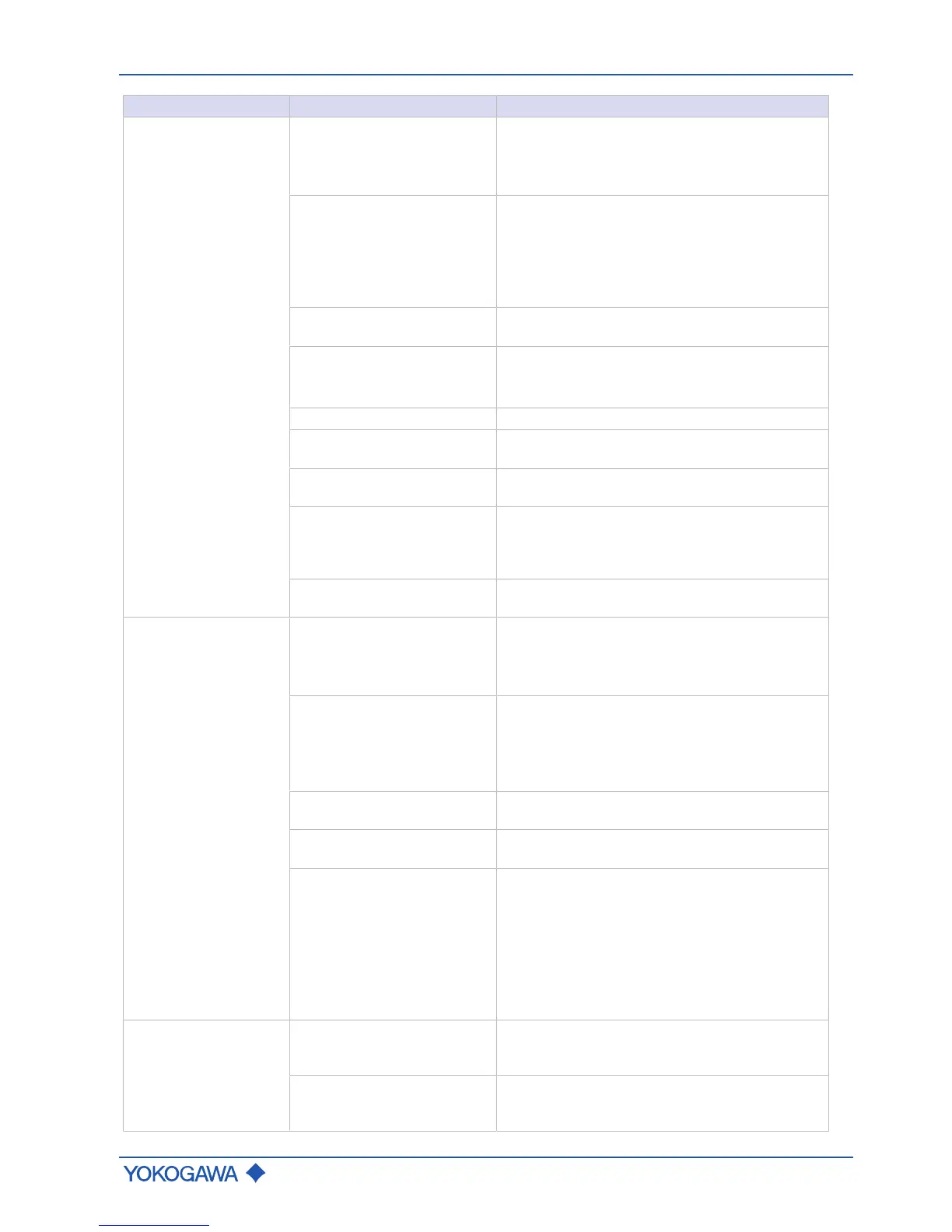

Malfunction Possible causes Remedy

Density displayed devi-

ating from actual density

Density unit, highest and low-

est value for density set incor-

rectly

– Match settings of flow meter and reading

system.

– Check LRV and URV process parameters,

see software instruction manual.

Fixed density

– Check whether the Val sel parameter is set

correctly. If a fixed value is selected, ensure

that the parameter Fix val is set correctly, see

software instruction manual.

– Set parameter Val sel to Meas val, see soft-

ware instruction manual.

Analog output trim was per-

formed incorrectly

– Correctly perform trimming, see applicable

software instruction manual.

No electrical grounding

– Ground transmitter and sensor, see [}31].

– Check correct connection of connecting cable

shield on transmitter.

Bubbles in medium

– Check pipe and installation, see [}16].

Connecting cable incorrectly

connected for remote type

– Check cable connections and correct, if

necessary, see [}33].

Faulty temperature measure-

ment

– Check temperature measurement circuits

TP1 – TP3 of connecting cable.

Corrosion and erosion

– If corrosion or erosion due to corrosive media

is suspected, contact Yokogawa and have

density and mass flow recalibrated, if neces-

sary.

Contaminated measuring

tubes

– Clean measuring tubes.

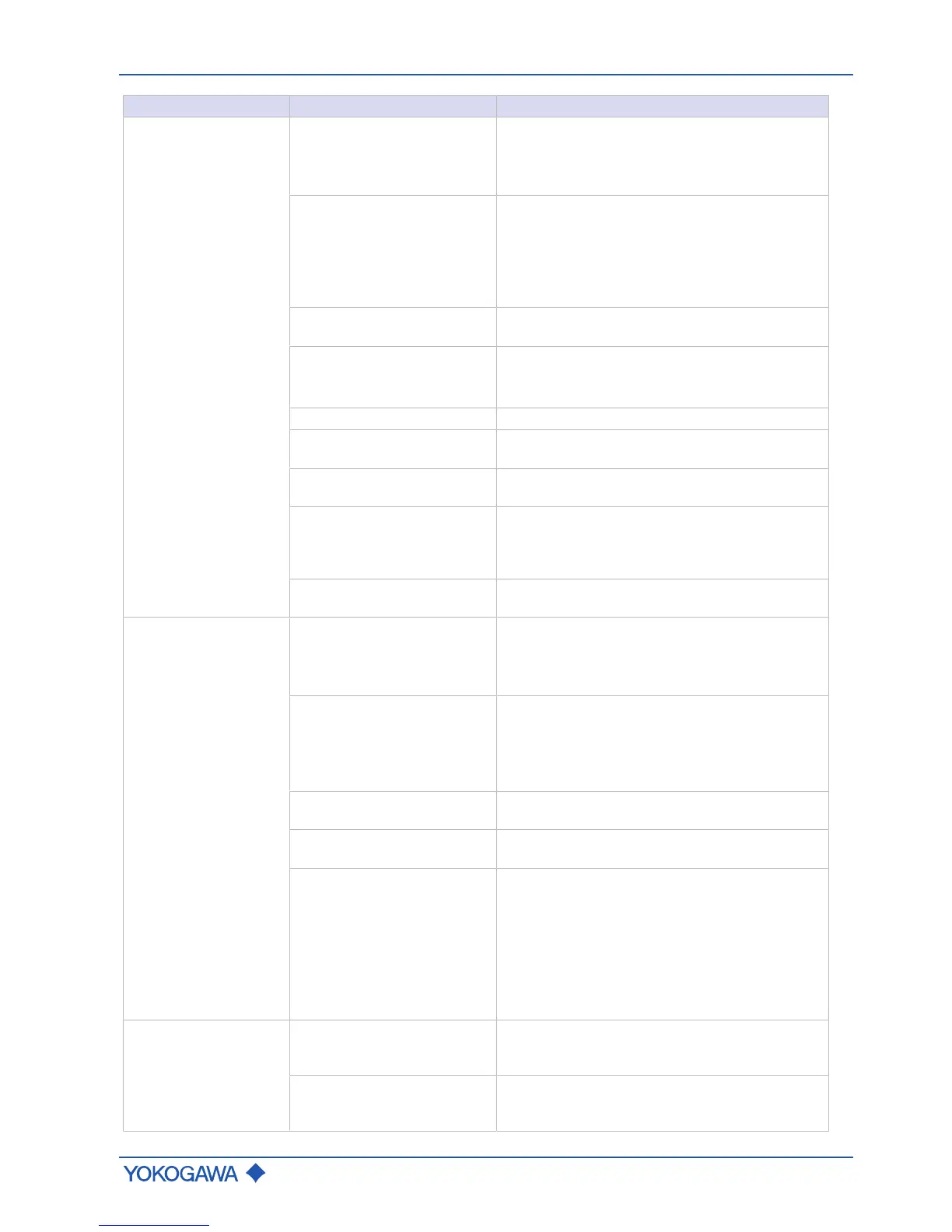

Temperature displayed

deviating from actual

temperature

Temperature unit, highest and

lowest value for temperature

set incorrectly

– Match settings of flow meter and reading

system.

– Check LRV and URV process parameters,

see applicable software instruction manual.

Non-adjustable temperature

– Check whether the Func sel parameter is set

correctly. If a fixed value is selected, ensure

that the Fix val is set correctly, see applicable

software instruction manual.

– Set parameter Func sel to Inter val.

Analog output trim was per-

formed incorrectly

– Correctly perform trimming, see applicable

software instruction manual.

Connecting cable incorrectly

connected for remote type

– Check cable connections and correct, if nec-

essary, see [}33].

Incorrect temperature mea-

surement with remote type

– Check temperature measurement circuit by

measuring resistance between TP1/TP2 and

TP1/TP3. Each value must be between 50 –

200 Ω.

– Check temperature measurement circuit TP2/

TP3 and make sure that resistance is < 10 Ω.

– Connect Pt100 simulator and check tempera-

ture measurement.

Output signal deviating

from measured quantity

Incorrect parameter

– Check parameter LRV and URV of the corre-

sponding output signal, and correct, if neces-

sary.

Incorrect measured quantity

– Check measured quantity output and, if nec-

essary, correct; check parameter Sel, see ap-

plicable software instruction manual.

Loading...

Loading...