<Toc> <Ind>

6-11

TI 05C01E02-01E 1st Edition : Oct. 31, 2001-00

•

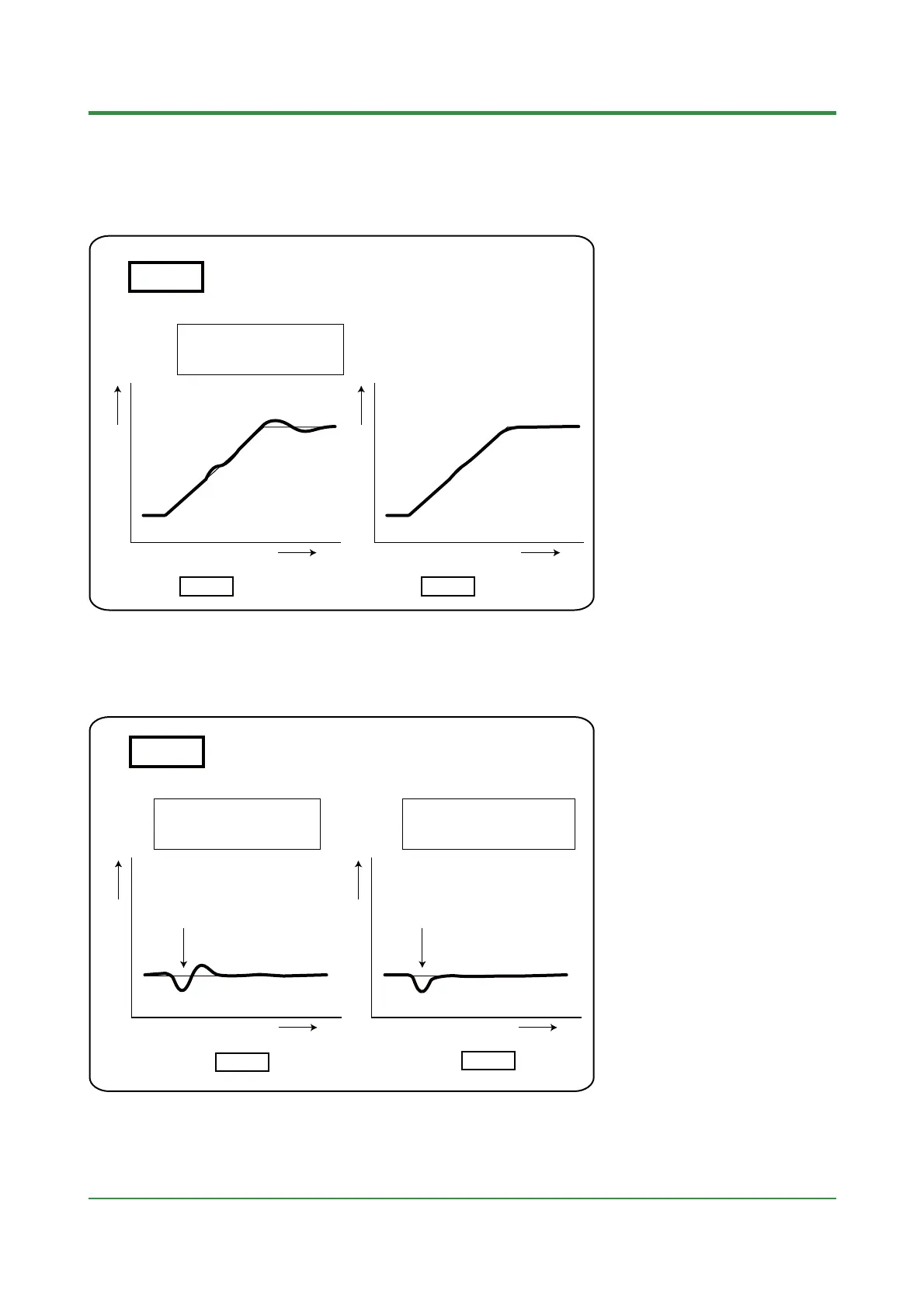

Due to the gain changes that occur at

the transition from ramp to soak,

conventional controls are inevitably

prone to overshoot. Yet, if the PID

constants are set so that the output

stabilizes more quickly in order to avoid

overshoot, the temperature ramp will lag

behind the prescribed pattern.

•

By using the "SUPER" function, the

temperature up ramp can be made to

follow the pattern almost exactly, and

significant savings can be achieved.

Example of ramp to soak transition overshoot suppression control

Process: Small electric furnace

P = 1.8% I = 317 sec D = 79 sec

(from auto-tuning)

SUPER effects (2)

Temperature

Time

Temperature

Time

Without SUPER With SUPER

•

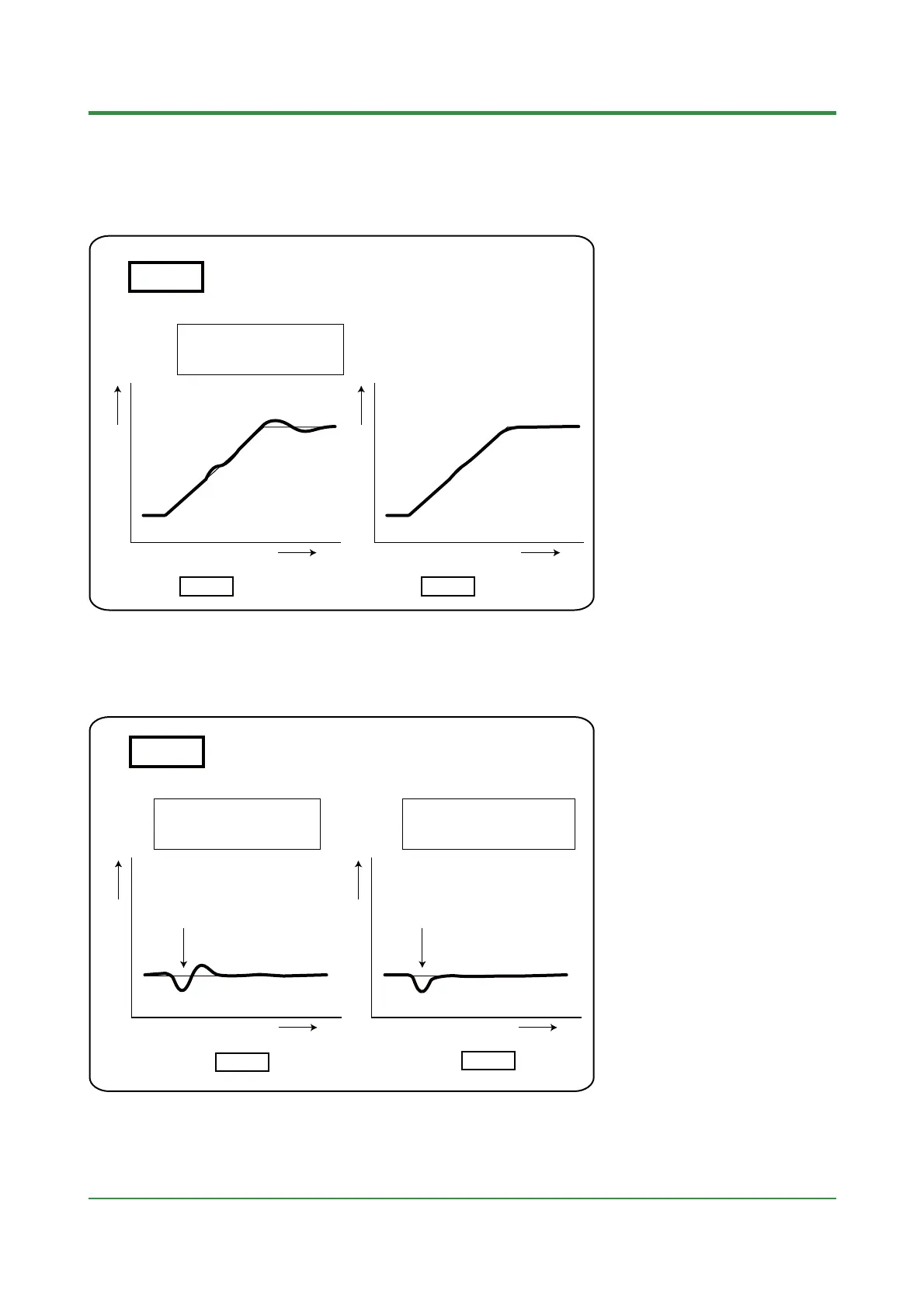

The "SUPER" function is extremely

effective for improving response to

disturbances. The overshoot

experienced with conventional PID

control in correction for disturbances is

significantly reduced, and settling time is

greatly speeded up.

Example of overshoot suppression control on response to disturbances

Process: Kiln

P = 6.2% I = 311sec D=77 sec

(from auto-tuning)

SUPER effects (3)

Without SUPER

With SUPER

Process: Kiln

P = 4.3% I = 684 sec D = 171 sec

(from auto-tuning)

Temperature

Time

Temperature

Time

Disturbance Disturbance

Loading...

Loading...