JOHNSON CONTROLS

9

FORM 160.69-O1

ISSUE DATE: 9/30/2012

1

Each compressor also has a Discharge Temperature

thermistor and High Pressure safety device.

There are two Liquid Line Solenoid Valves and two

Oil Return Solenoid Valves, one for each compressor.

A lockout can be performed on a compressor to pre-

vent it from running. Only one compressor at a time

can be locked out.

Two CM-2 Current Boards, one for each compressor

motor, provides motor Overload and Power Fault pro-

tection.

The Oil System consists of a common Oil Sump for

both compressors. A single Oil Heater maintains prop-

er Sump temperature when both compressors are shut-

down. This temperature is monitored by the Oil Tem-

perature Thermistor. There are two Oil pumps, one for

each compressor. Each is driven by a Variable Speed

Oil Pump Drive. The oil pressure is monitored by a

common Sump oil pressure transducer monitoring the

low side pressure. Two Pump oil pressure transduc-

ers, one for each compressor, monitor the high side oil

pressure for each compressor.

SECTION 1 – DESCRIPTION OF SYSTEM

AND FUNDAMENTALS OF OPERATION

SYSTEM OPERATION DESCRIPTION

The following is a high level description of the chill-

er control. It describes the overall operation. Control

Center components, chiller components and program-

mable setpoints are referenced. Refer to Figure 2 on

page 15 to view the chiller operation flowchart.

The YD dual compressor chiller consists of one evapo-

rator, one condenser, two oil pumps and two compres-

sors. Other than capacity control, the basic operation is

similar to a standard YK Centrifugal Chiller.

The use of two compressors requires valves on the dis-

charge line of each compressor. When a compressor

is shutdown, its discharge valve is closed to prevent

compressor backspin due to a gas flow from the run-

ning compressor. An end switch at both the closed and

open positions provides indication of full open and

full closed positions. The valves can be manually con-

trolled.

Each compressor Pre-rotation Vane assembly is

equipped with a potentiometer to provide vane posi-

tion. A calibration procedure assures displayed posi-

tion accuracy. The vanes can be manually controlled.

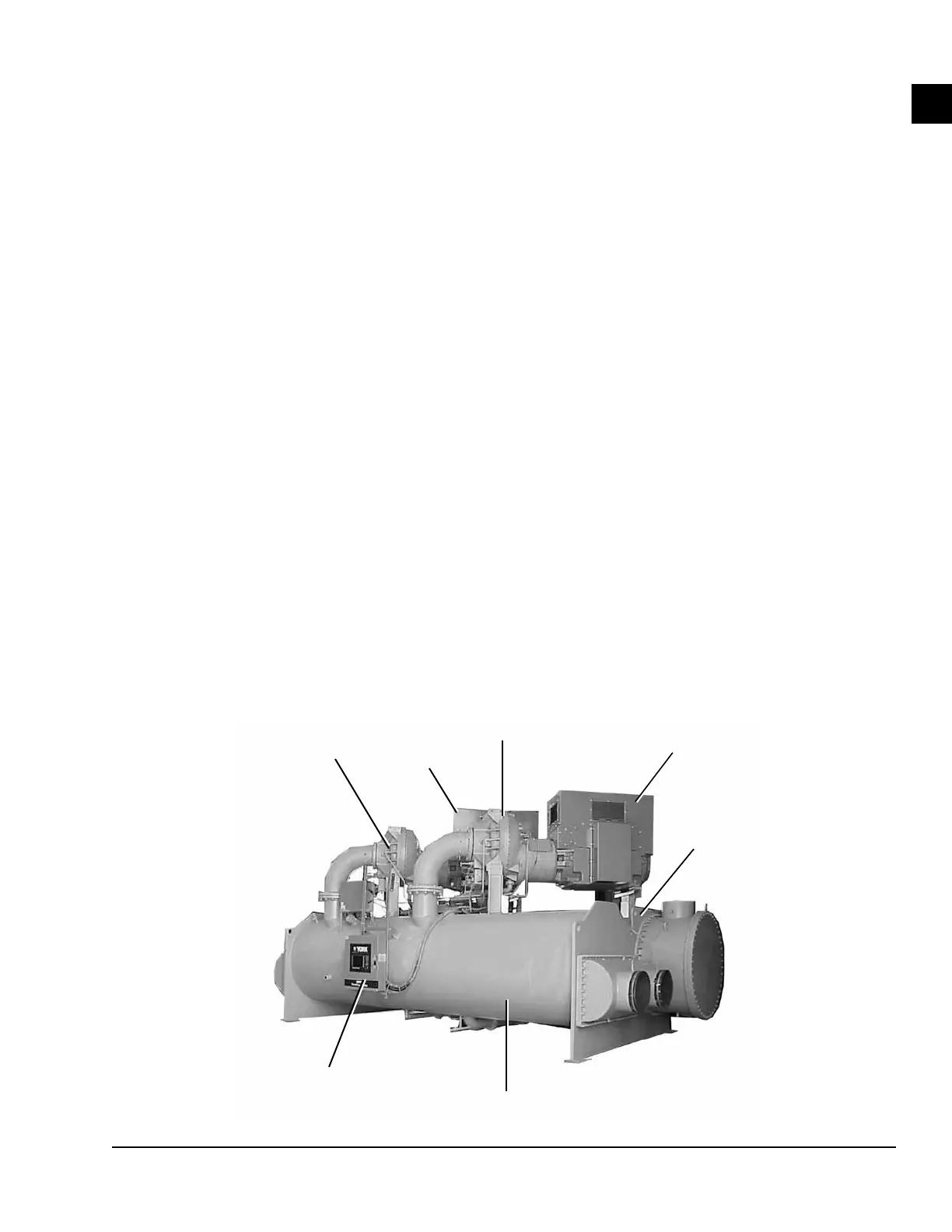

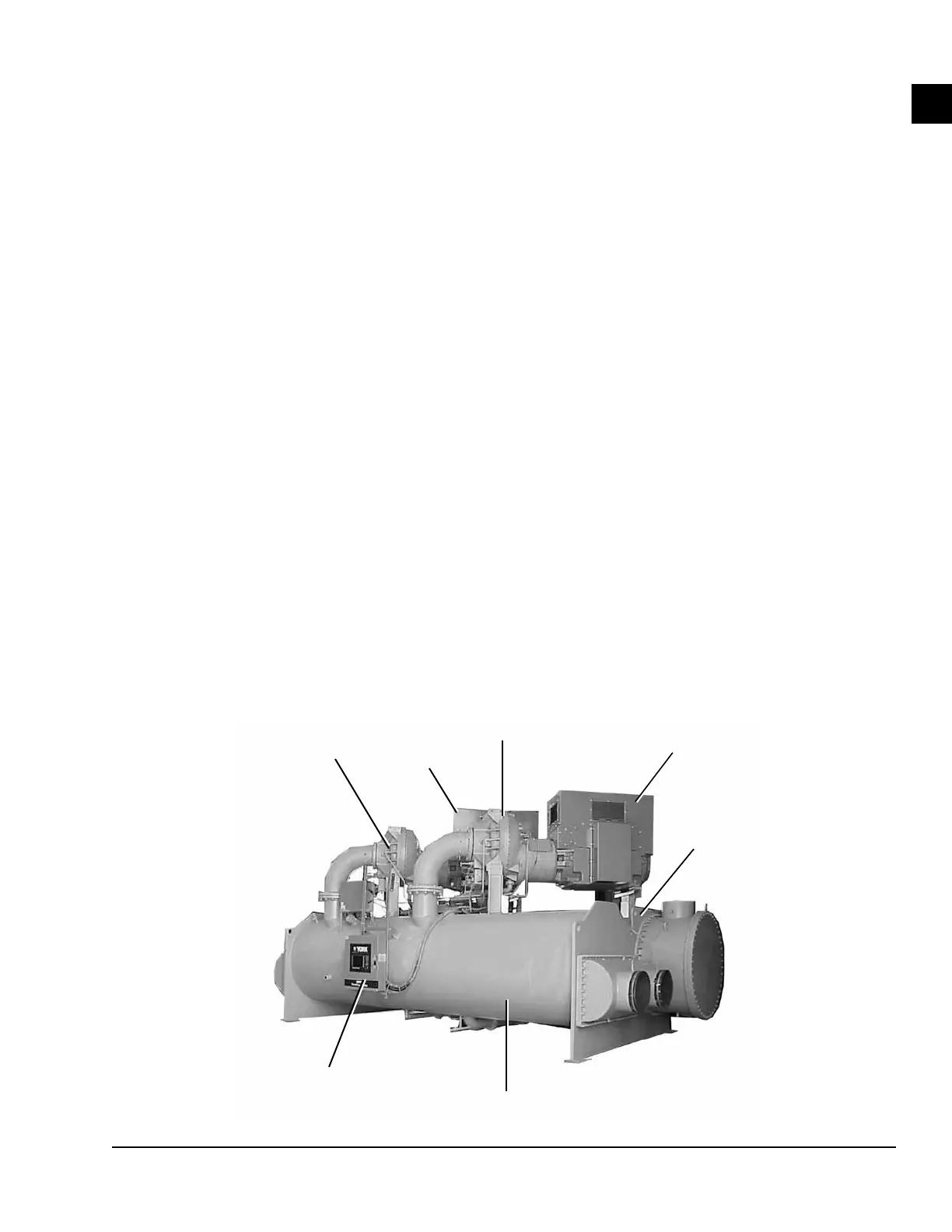

FIGURE 1 - MODEL YD CHILLER

COMPRESSOR 1

COMPRESSOR 2

MOTOR 1

MOTOR 2

CONTROL

CENTER

EVAPORATOR

CONDENSER

LD08634

Loading...

Loading...