Cable Clearance Check Procedure

The printer cables and connectors must not interfere (touch) with any

moving components (belts, gears or springs).

Placement of cable tie points, tie anchors, and cable tension and slack areas are outlined in the

following steps:

980428-109 Rev. 1 Prelim. 25

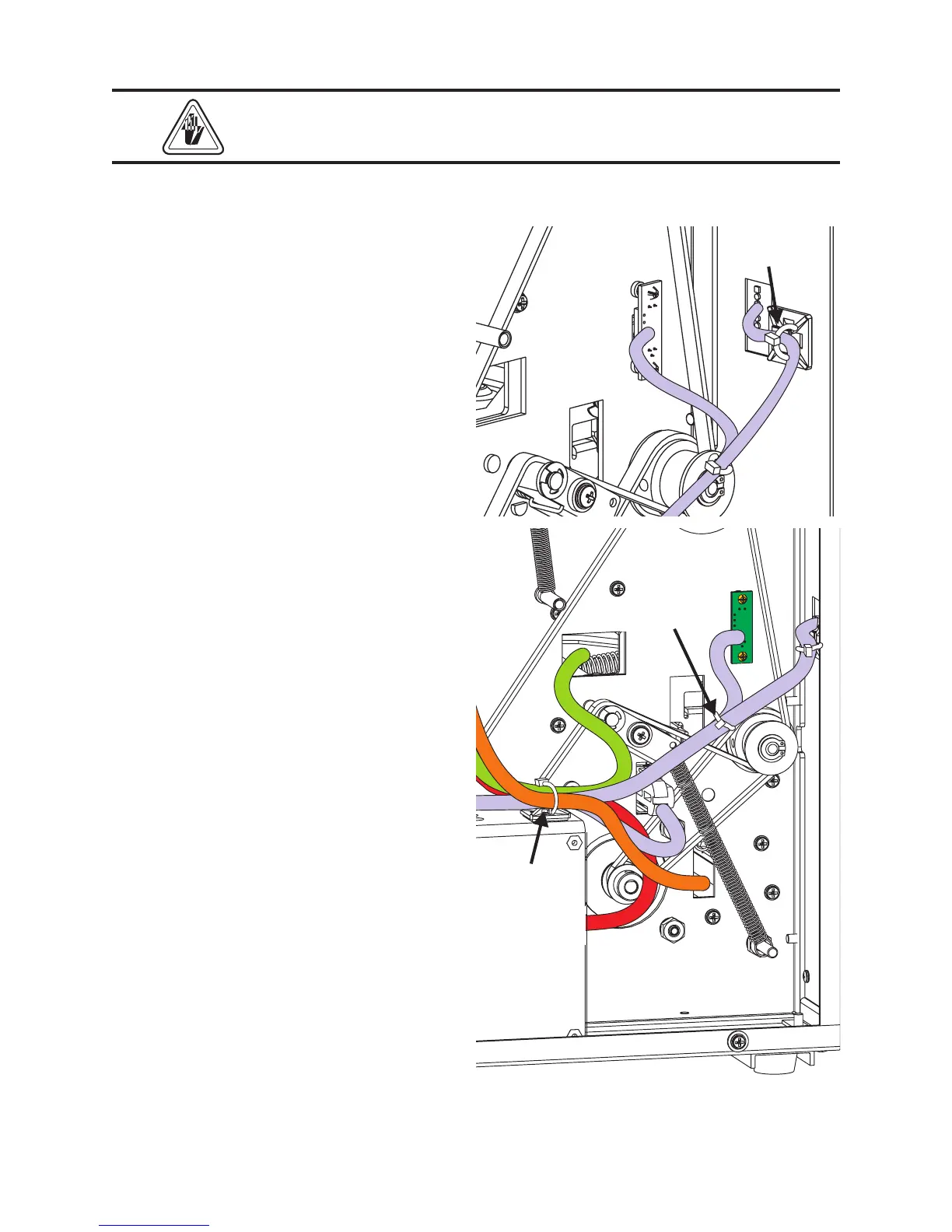

Control Panel Tie Point

1. Pull the control panel cable until minimum

1/4" service loop (slack) is present between

the cable tie and control panel PCBA.

Tighten the tie and cut off the excess.

Cable Tie

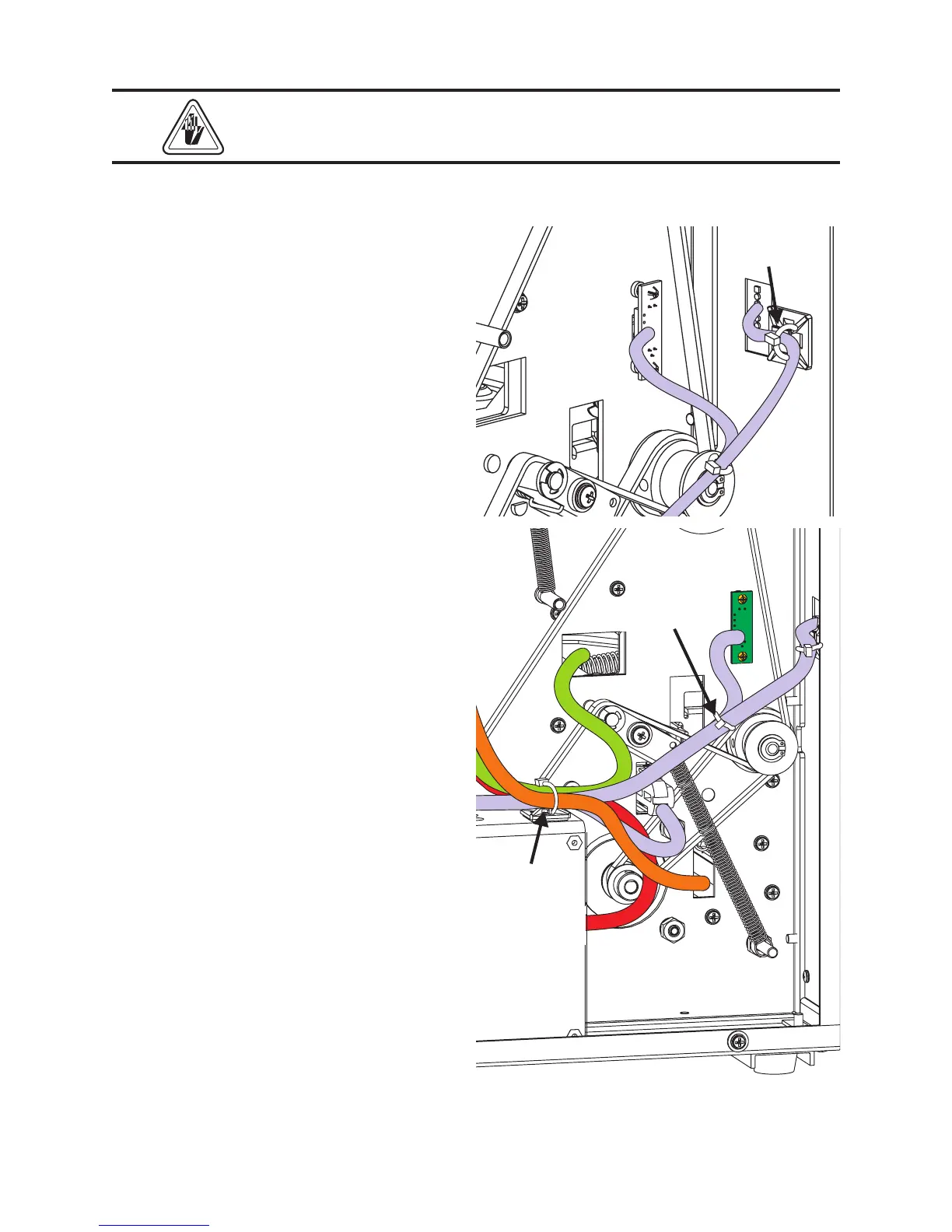

Front Power Supply Cable Tie Point

1. Loosely tie the DC power, control panel,

head-up, label sensor, and motor cables

with a cable tie through the front anchor tie

on top of the power supply.

2. Push the label sensor slide to the maximum

distance into the user side of the printer. Pull

the sensor cables through the power supply

anchor tie towards the main PCBA, taught

but not strained. Tighten the tie.

3. Pull the control panel cable through the

power supply anchor tie towards the main

PCBA, taught but not strained.

4. While holding the head-up cable one-half

inch parallel to the center panel of the

head-up PCBA, connect the head-up cable

to the control panel cable with a cable tie.

Pull the head-up cable taught to the power

supply’s front cable anchor tie.

Cable Tie

Front

Anchor Tie

Loading...

Loading...