6

155980

PERFORMANCE CHARACTERISTICS

CONDITION POSSIBLE CAUSE REMEDY

A

PUMP WILL NOT START OR

RUN

Inadequate incoming water pressure. Check incoming water line for closed valve, low water

pressure or clogged lter/strainer.

Excessive incoming water pressure. Install regulator and reduce pressure below 100 PSI with

valve closed.

Debris around intake. Clear debris from pit and foot valve strainer.

Float hung up on pit or primary pump Move pumps so that the oats move freely and do not

contact pit, piping or each other.

Control valve is under tightened Control valve adjustment on page 4.

B PUMP STARTS TOO SOON Float valve is positioned too low. Refer to STEP 3.

C PUMP WILL NOT SHUT OFF

Float is obstructed. Inspect oat operation and correct problem.

Internal valve diaphragm vent hole is

plugged with debris.

Turn off water supply to pump and back on repeatedly

to dislodge debris. If this process does not remedy the

problem, service pump to clear debris or replace valve

assembly.

Control valve is overtightened Control valve adjustment on page 4.

D

PUMP OPERATES BUT

DELIVERS LITTLE OR NO

WATER

Debris around intake. Clear debris from pit and foot valve strainer.

Inadequate incoming water pressure. Check incoming water line for closed valve or low water

pressure.

Blockage in discharge pipe. Remove pipe and ush out debris.

Foot valve above water level. Adjust oat - Refer to STEP 3 on page 3.

Vertical lift too high. Change discharge piping or contact technical service.

Troubleshooting Guide

© Copyright 2020 Zoeller

®

Co. All rights reserved.

Pump capacity varies due to: Inlet water pressure, working water pressure, discharge

elevation, number of pipe ttings, inlet and outlet pipe size, uid viscosity, degree of water

clarity, water temperature. The ow rates in the chart are approximate values.

NOTE: Some districts may require a reduced pressure principle backow preventer per ASSE

Standards 1013. Check local codes.

Sump water is non-potable. To reduce the risk of contamination of the

potable water supply, the FLEX

™

must be installed with a listed backow

device suitable for the installation, in accordance with the local plumbing code, such as a

reduced pressure principle backow preventer (RP). Alternately, consult the local plumbing

and health codes or the authority having jurisdiction for guidance on cross-connection and

backow protection requirements.

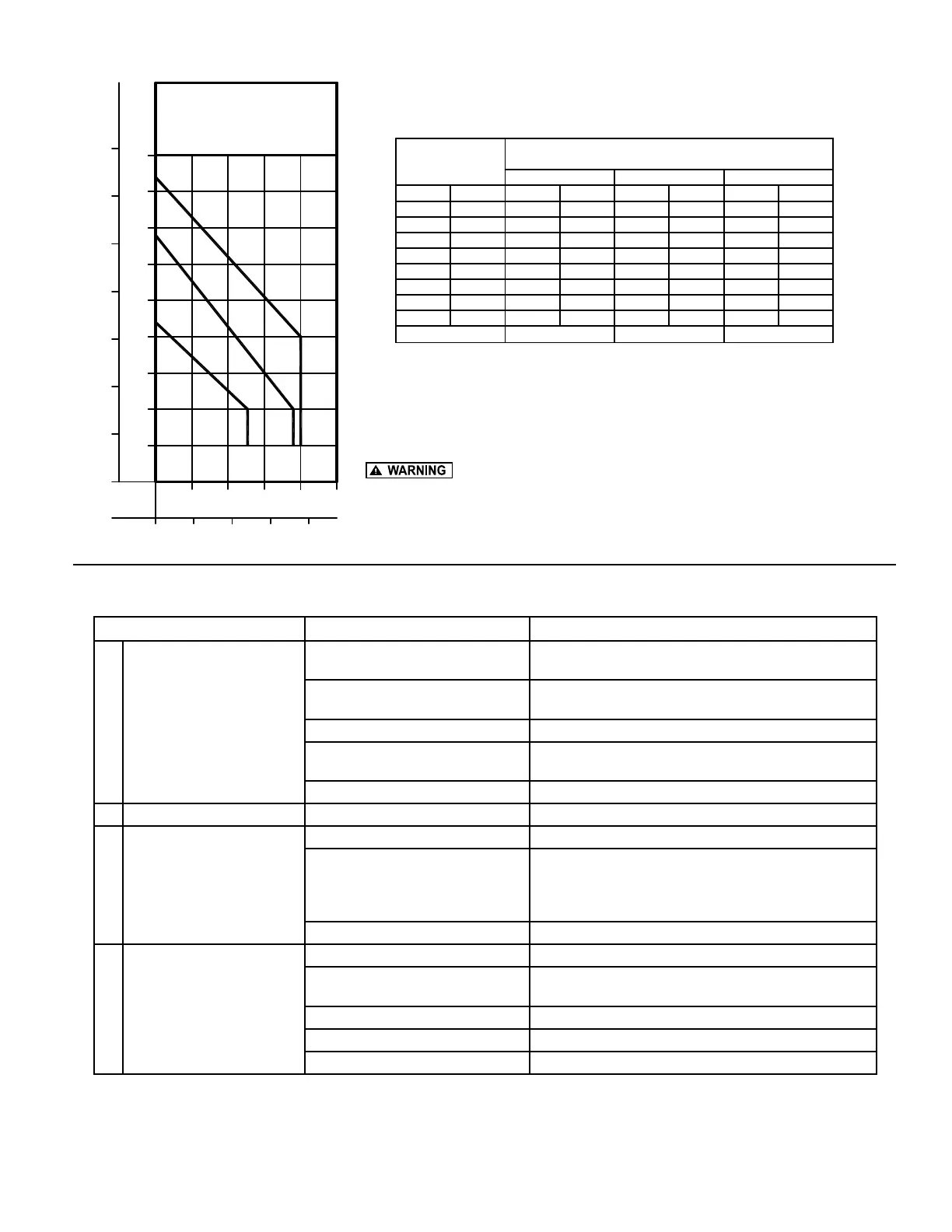

TOTAL DYNAMIC HEAD/FLOW

PER MINUTE

DEWATERING ONLY

TOTAL DYNAMIC HEAD

FLOW PER MINUTE

15

LITERS

0

GALLONS

20 40

5 10

0

2

5

25

8060

20

PUMP PERFORMANCE

CURVE

MODEL 540

FEET

METERS

4

10

15

6

45

30

25

20

40

35

8

10

12

14

40 PSI

60 PSI

80 PSI

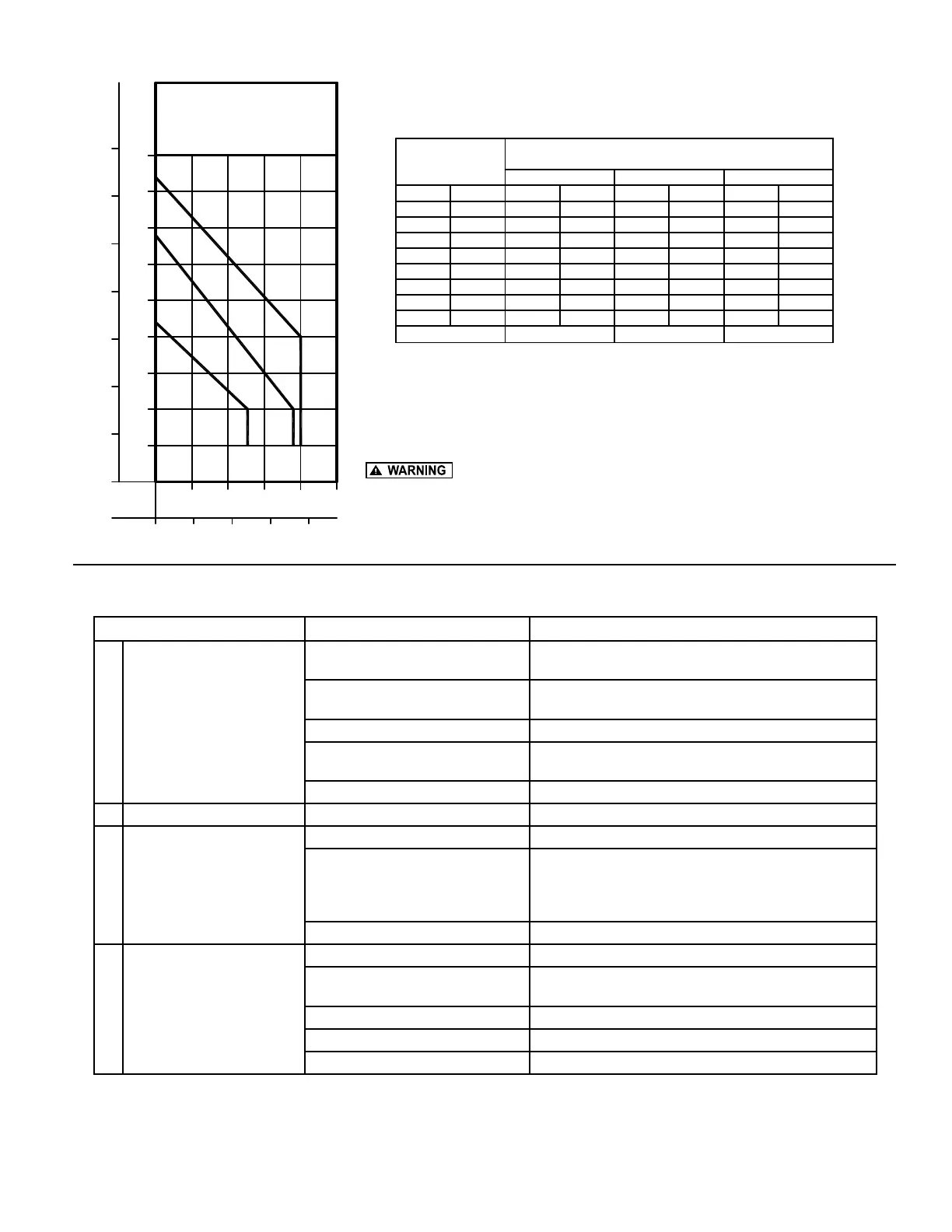

TOTAL DYNAMIC HEAD/FLOW

PER MINUTE

DEWATERING ONLY

MODEL

540

40 PSI 60 PSI 80 PSI

Feet Meters Gal.

Liters

Gal.

Liters

Gal.

Liters

5 1.5 12.7 48.1 19.0 72.0 20.0 75.7

10 3.0 12.7 48.1 19.0 72.0 20.0 75.7

15 4.6 7. 4 28.0 15.0 56.8 20.0 75.7

20 6.1 2.0 7. 6 11. 1 42.0 20.0 75.7

25 7. 6 - - 7. 1 26.9 15.3 57.9

30 9.1 - - 3.2 12.1 10.9 41.3

35 10.7 - - - - 6.4 24.2

40 12.2 - - - - 1.8 6.8

Shut-off Head:

22.0 ft. (6.7m) 34.0 ft. (10.4m) 42.0 ft. (12.8m)

Loading...

Loading...