起

重

机

说

明

Ma

in

t

en

an

c

e

Maintenance Manual for Crawler Crane

(1) Treat the collected waste diesel according to relevant environmental protection

regulations, and do not discharge it into the environment.

(2) Take preventive measures to avoid fires when cleaning the fuel tank.

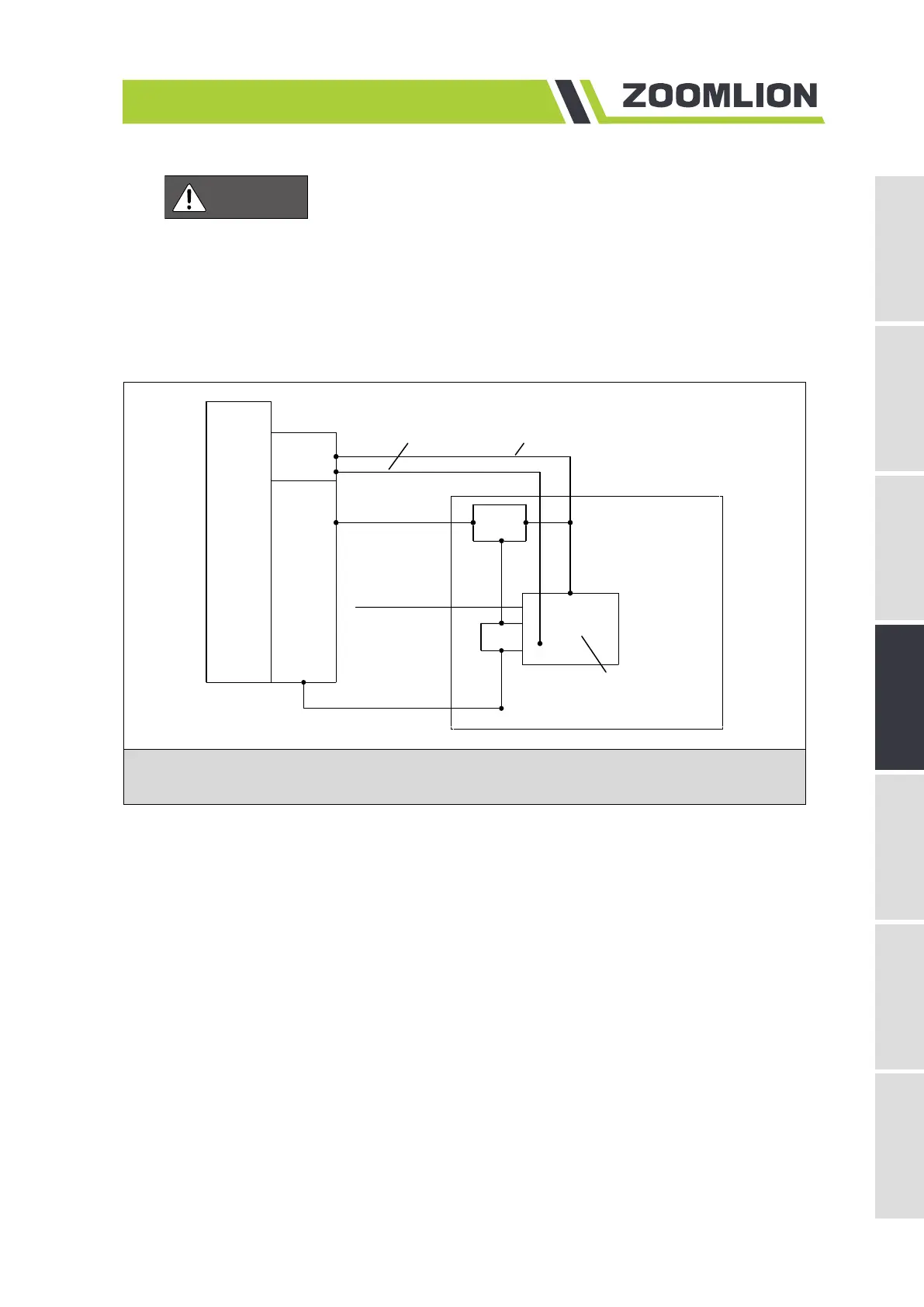

4.6.3 Cooling system

Position of cooling system: at the rear part of the slewing table, near the engine.

Figure 4-12 Cooling system

4.6.3.1 Inspection of coolant level

The coolant of engine might reduce continuously due to leakage and evaporation. Severe lose

of the coolant will result in poor capability for heat dissipation of the engine, thus causing

damages to the engine.

Method of inspecting coolant level:

a) Observe the transparent window on one side of the expansion tank. If the coolant level can

be seen in the window, then the coolant is enough. Otherwise, supplement is needed.

b) If there is no inspection hole, open the cover of expansion tank to make sure that the

coolant level is 1/2 to 2/3 of the total volume. If the coolant level is less than 1/2 of the total

volume, supplement is needed.

Check the cold-proof capacity of the coolant before each cold season comes. Or you can

consult the operating instructions of the engine manufacturer.

Supplement of coolant: open the cover of the expansion tank and put proper amount of coolant

into it to make the fluid level be visible through the window.

Connected to engine

water outlet

Thermostat

Water outlet

Connected to engine

water inlet

Water pump

Engine

3/4 NPTF

(Warm-air water return port)

Connected to engine water inlet Connected to engine exhaust port

4-17

Loading...

Loading...