起

重

机

说

明

Ma

in

t

en

an

c

e

Maintenance Manual for Crawler Crane

4.9.1.2 Cleaning of the crawler

Clean the crawler when it is dirty. Since when the crane is dirty, it needs more energy to move,

thus increasing wear of the crane.

The cleaning involves wiping off the dirt on track pad, sundries on the crawler carrier, and soil

being mingled in between the drive sprocket or track roller and the track pad, etc.

4.9.1.3 Lubrication of the track pad connecting pin

Put the track pad connecting pin in a proper position so that the service personnel can spray

the connecting pin with lubricant. Move the crane forward until the lower track pad connecting

pins are located on track carrier roller, and then spray them with lubricant. Make sure that the

lubricant can penetrate into the connection hole between the track pad connection pin and the

track pad.

Lubricate the track pad connecting pin after cleaning the crawler carrier and before

tensioning of crawler parts.

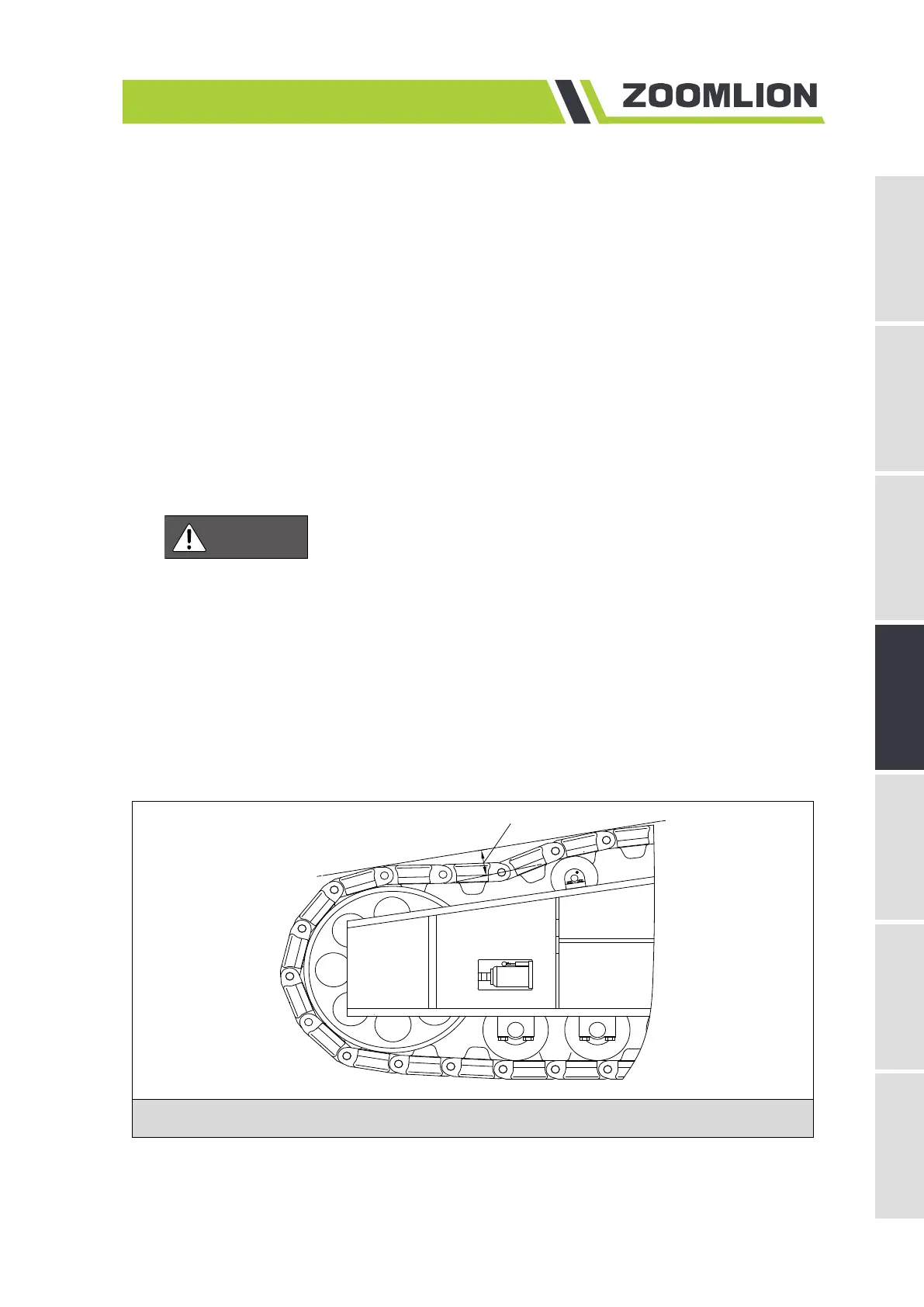

4.9.1.4 Tension of track pad

The tension of track pad is a standard judging whether the track pad is strengthened. The

tension of track pad is estimated by its relaxation (L) around 40 ± 5 millimeter (for

ZCC1300/ZCC1800 crawler crane) and 50±5 mm (for ZCC2600 crawler crane) after proper

cleaning and strengthening, and the crawler components must be tightened or loosened

subject to their tightness.

Figure 4-27 Judging of track pad tension

L

4-41

Loading...

Loading...