North American - ENG

Date Released:

October 2018

3M-Matic

™

8000af - Type 11800

Page 18

44-0009-2153-4 / ECO# 0078045

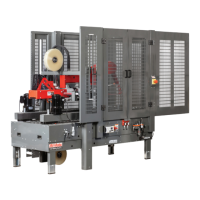

Figure 7-2

Figure 7-1

7.1 Operating Conditions

The machine should operate in a

dry and relatively clean environment

(See Speci cations).

7.2 Space Requirements for

Machine Operation and

Maintenance Work

Minimum distance from wall

(Figure 7-1):

A = 1000mm.

B = 700mm.

Minimum height = 2700mm.

7.3 Tool Kit Supplied with Machine

A tool kit containing some tools are

supplied with the machine. These

tools should be adequate to set-up

the machine, however, other tools

supplied by the customer will be

required for machine maintenance.

7.4 Machine Set-Up / Bed Height

1 - Lift the machine with belts or

ropes paying attention to place

belts in the points (Figure 7-2).

To set the machine bed height,

do the following:

2 - Adjust machine bed height.

The case sealer is equipped

with four (4) adjustable legs

that are located at the corners

of the machine frame.

The legs can be adjusted to

obtain di erent machine bed

heights (Figure 7-3).

Also refer to “Speci cations”

3 - Lock the screws.

4 - Repeat the operation for all legs.

(It is not necessary to x or

anchor the machine to the oor).

5 - For Outer Column Positioning -

The columns are shipped in a

lower position.

To Adjust Columns - See Special

Set-up Procedure (Section 11) .

7. Installation

B

A

Figure 7-3

M8 x 1.25mm

Socket Head

Screws

Adjustable

Leg

Loading...

Loading...