North American - ENG

Date Released:

October 2018

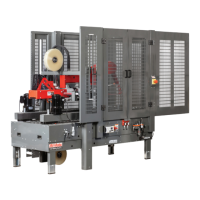

3M-Matic

™

8000af - Type 11800

Page 46

44-0009-2153-4 / ECO# 0078045

The Troubleshooting Guide lists some possible machine problems, causes and corrections.

Also see Manual 2 "Troubleshooting" pages for taping head problems.

Note – Adjustment of the machine or taping heads are described in “Adjustments”.

Problem

Drive belts do not convey boxes

Drive belts do not turn

Drive belts break

Squeaking noise as boxes

pass through machine

Tape not centered on box seam

Flap kicker kicks at wrong time

Gate does not raise to stop

next box

Gate retracts too soon/

kicker does not kick

Cause

Worn drive belts

Top taping head does not

apply enough pressure

Taping head applying spring

holder missing

Taping head applying spring

set too high

Worn or missing friction rings

Drive belt tension too low

Electrical disconnect

Motor not turning

Energy Stop Button engaged

Worn belt

Dry compression bearings

Dry column bearings

Centering guides not centered

Box aps not of equal length

Kicker cam improperly set

Air cylinder ow controls out

of adjustment

Too much air pressure on gate

cylinder lifts box o of gate cam

Incoming boxes not low

enough and therefore not

actuating cam

The removable portion of the

gate cam has been removed

and boxes shorter than 12

inches are being run

Correction

Replace drive belts

Adjust the box height adjustment

with the crank

Replace spring holder

Reduce spring pressure

Replace friction rings

Adjust belt tension

Check power and electrical plug

Evaluate problem and correct

Insert box in machine to re-start

Replace belt

Lubricate compression bearings

Lubricate column bearings

Adjust centering guides

Check box speci cations

Reposition kicker cam

Readjust ow controls

Reduce gate air pressure using

regulator

Reinstall removable gate cam

portion

15.1 Troubleshooting Guide

15. Troubleshooting

Loading...

Loading...