NA - ENG

April 2017

3M-Matic

™

Accuglide 3 - 2 Inch Taping Head

Page 15

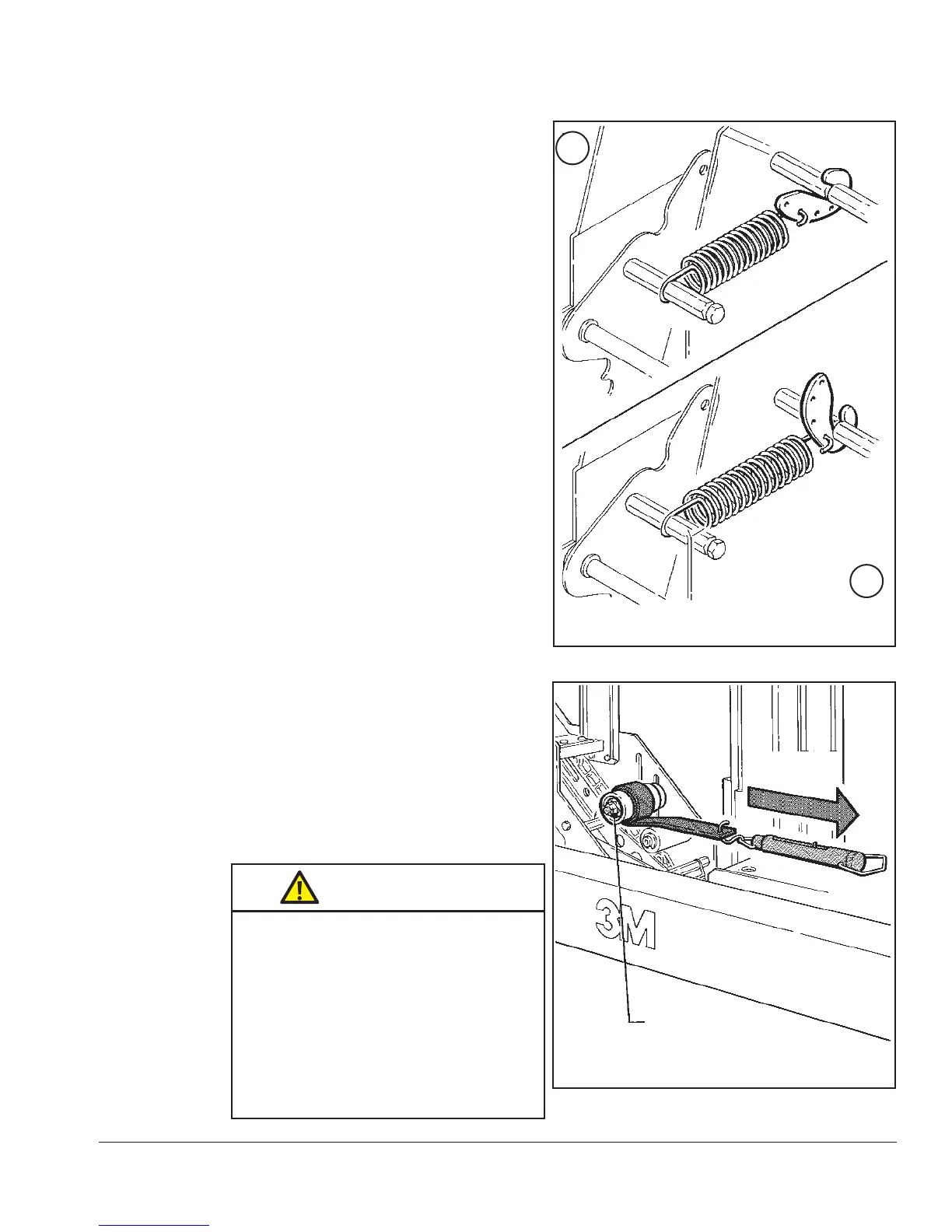

Applying Mechanism Spring

To obtain access to spring, remove

taping head cover (four mounting

screws). Replace cover to nish.

The applying mechanism spring,

shownin Figures 5-4A and 5-4B,

controls applying/bu ng roller

pressure on box and returns the

mechanism to reset position. The

spring pressure is pre-set, as shown

in Figure 5-4A for normal operation,

but is adjustable. If a tape gap

appears on trailing surface of box

increase spring pressure. If front of

box is being crushed by applying

roller decrease spring pressure.

Removing spring end loop from

spring holder and placing loop in

other holes provided to adjust

spring pressure (see Figure 5-4B.

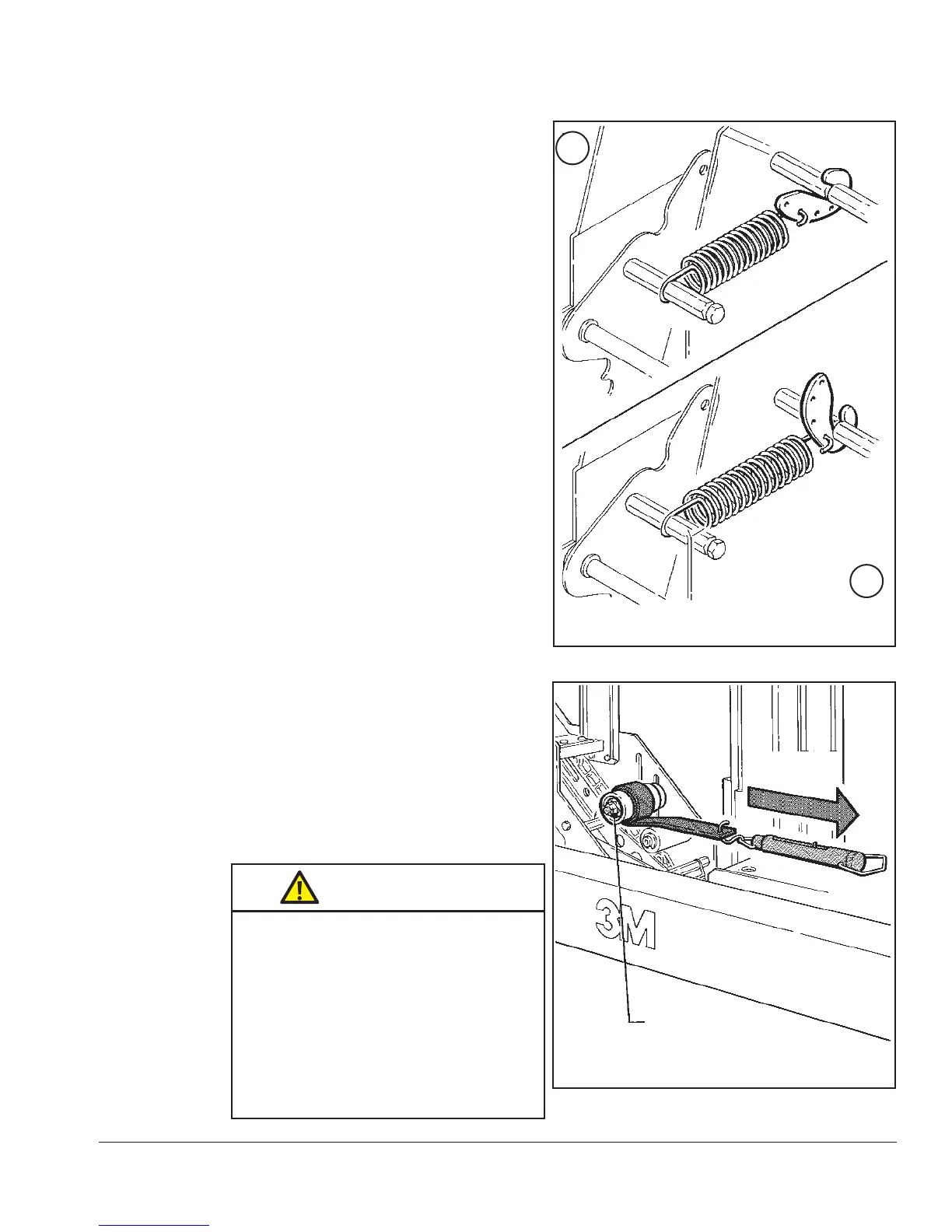

One-Way Tension Roller

Figure 5-5

The one-way tension roller is factory

set. When replacing this assembly,

the roller must have 0,5 kg [1 lb.]

min. tangential force when turning.

To Adjust Tension:

1. Wrap a cord or small strap

(non-adhesive) 4-6 turns around

the tension roller.

2. Attach a spring scale to the end of

the cord or strap.

3. Turn adjusting nut (with socket

wrench provided) until required

force of approximately 0.5 kg to

0.9 kg [1 to 2 lbs.] is reached to

turn roller pulling on spring scale.

Figure 5-4 Applying Mechanism Spring

Figure 5-5 One-Way Tension Roller

(Adjustments continued on next page.)

0.5 - 0.9kg

[1/2 lbs.]

Adjusting Nut

A

B

Adjustments (continued)

• To reduce the risk associated with

shear, pinch, and entanglement hazards

- Turn air and electrical supplies o

on associated equipment before

performing any adjustments, mainte-

nance, or servicing the taping heads

- Never attempt to work on the taping

head or load tape while the box

drive system is running

WARNING

Loading...

Loading...