VCC-X Operator Interface SD

VCC-X SETPOINTS

47

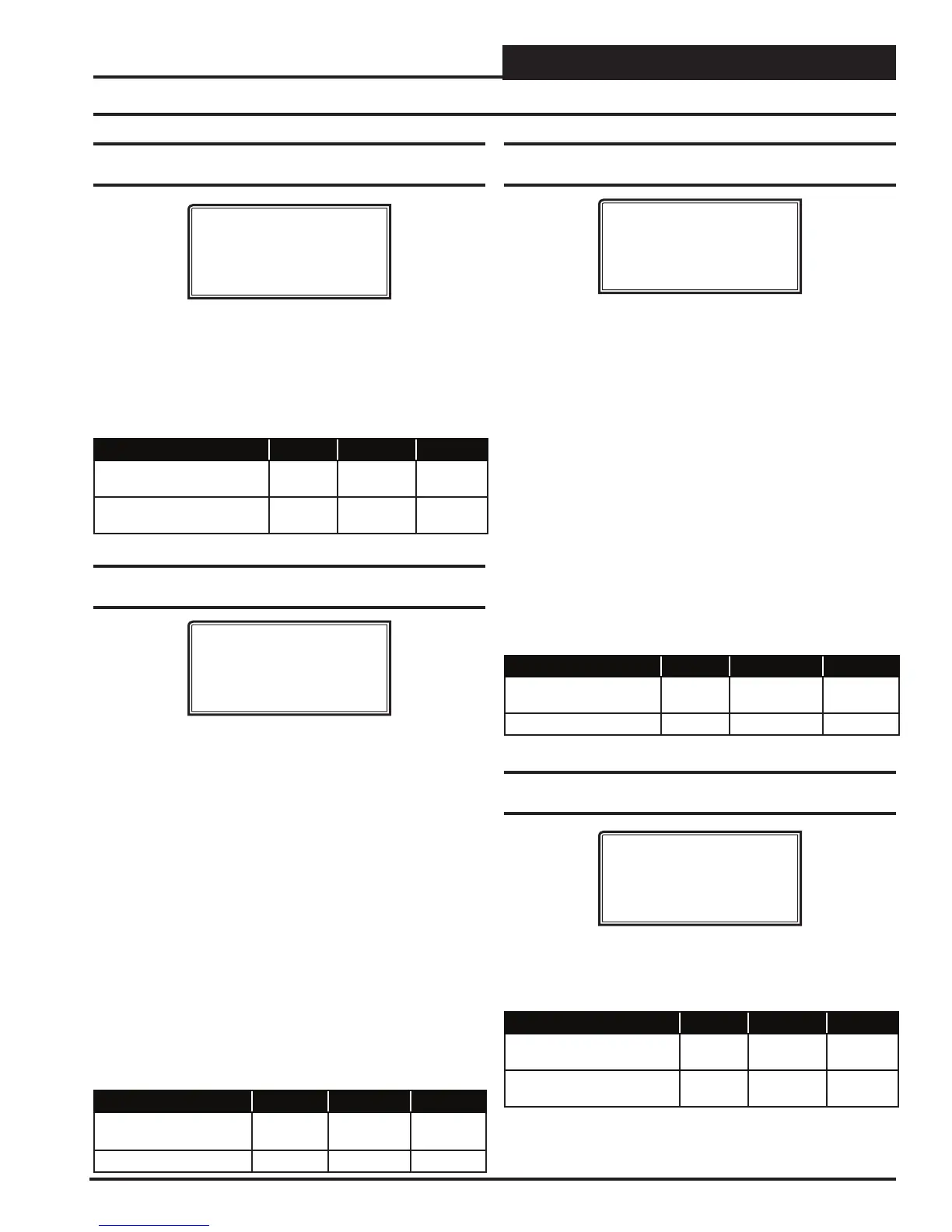

Setpoint Screen #22 - Stage Off Window -

Cooling/Heating

VCC-X Spts ID:#

Stage Off Window

Cooling: 5.0ºF

Heating: 5.0ºF

When the VCC-X Controller is in Cooling Mode, if the Supply Air

Temperature drops below the Active Supply Air Cooling Setpoint

minus the Cooling Stage Off Window value, a Cooling Stage will be

deactivated after its Minimum Run Time. In the Heating Mode, if the

Supply Air Temperature rises above the Active Supply Air Heating

Setpoint plus the Heating Stage Off Window value, a Heating stage

will be deactivated after its Minimum Run Time.

Description Minimum Default Maximum

Stage Off Window Cooling 1ºF

(.6ºC)

5ºF

(2.8ºC)

30ºF

(16.6ºC)

Stage Off Window Heating 1ºF

(.6ºC)

5ºF

(2.8ºC)

50ºF

(27.7ºC)

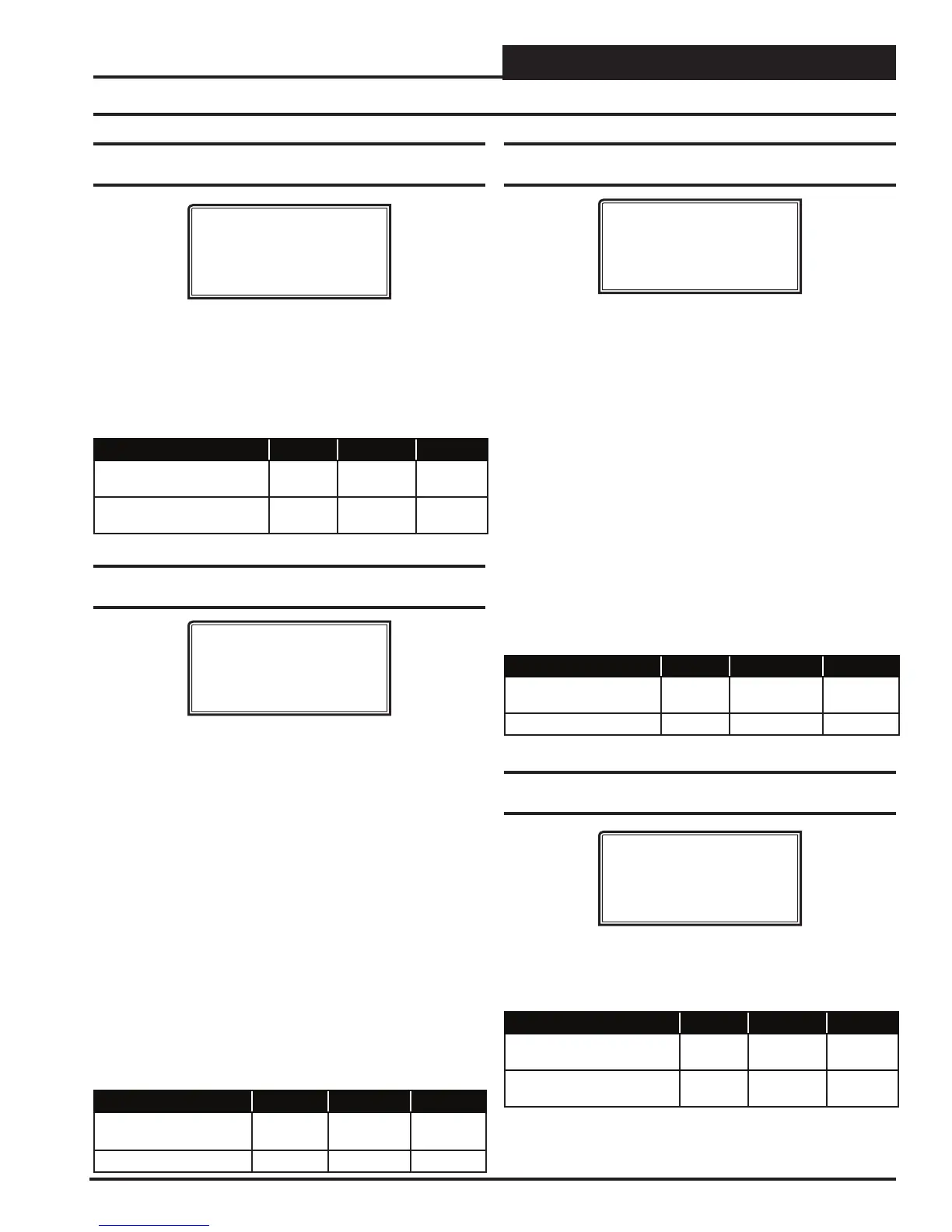

Setpoint Screen #23 - Mod Heat Proportional

Window and Time Period

VCC-X Spts ID:#

Mod Heat

Prop Window: 10.0ºF

Time Period: 30s

The Modulating Heating Proportional Window is the control range

of the Modulating Signal above and below the Active Supply Air

Temperature Setpoint. The size of the Proportional Window will

determine how much of a signal change the controller will make

per Time Period for every 1˚F the Supply Air Temperature is from

setpoint. The maximum signal change per time period is 10% which

occurs when the Supply Air Temperature is the full Proportional

Window amount from setpoint. So, with a 5˚ Proportional Window,

if the Supply Air Temperature is 5˚ or more from setpoint, the signal

change will be 10% per time period. At 4˚ difference, the signal

change will be 8% per time period. By the time the difference is 1˚,

the signal change will be 2% per time period. With a Proportional

Window of 2˚, if you are 2˚ or more from setpoint, the amount of

signal change will be 10% per time period, and at 1˚ from setpoint

the change would be 5% per time period. So, a larger proportional

window allows for fi ner tuning of the control signal to prevent

overshooting.

The Time Period is the length of time between Modulating Signal

adjustments. Short Time Periods may cause hunting of the Modu-

lating Signal.

Description Minimum Default Maximum

Mod Heat Proportional

Window

.1ºF

(.1ºC)

10ºF

(5.5ºC)

30ºF

(16.6ºC)

Mod Heat Time Period 5 sec 30 sec 240 sec

VCC-X Setpoint Screens

Setpoint Screen #24 - Mod Cool Proportional

Window and Time Period

VCC-X Spts ID:#

Mod Cool

Prop Window: 10.0ºF

Time Period: 30s

The Modulating Cooling Proportional Window is the control range

of the Modulating Signal above and below the Active Supply Air

Temperature Setpoint. The size of the Proportional Window will

determine how much of a signal change the controller will make

per Time Period for every 1˚F the Supply Air Temperature is from

setpoint. The maximum signal change per time period is 10% when

the Supply Air Temperature is the full Proportional Window amount

from setpoint. So, with a 5˚ Proportional Window, if the Supply Air

Temperature is 5˚ or more from setpoint, the signal change will be

10% per time period. At 4˚ difference, the signal change will be 8%

per time period. By the time the difference is 1˚, the signal change

will be 2% per time period. With a Proportional Window of 2˚, if

you are 2˚ or more from setpoint, the amount of signal change will

be 10% per time period, and at 1˚ from setpoint the change would

be 5% per time period. So, a larger proportional window allows for

fi ner tuning of the control signal to prevent overshooting.

The Time Period is the length of time between Modulating Signal

adjustments. Short Time Periods may cause hunting of the Modu-

lating Signal.

Description Minimum Default Maximum

Mod Cool Proportional

Window

.1ºF

(.1

ºC)

10ºF

(5.5ºC)

30ºF

(16.6ºC)

Mod Cool Time Period 5 sec 30 sec 240 sec

Setpoint Screen #25 - Head Pressure

Setpoints - Cooling and Reheat

VCC-X Spts ID:#

Head Pressure Spts

Cooling: 315psi

Reheat: 400psi

If a Head Pressure Transducer is connected to the RSM Module you

can control a Condenser Fan or a Condenser Water Valve to maintain

these Head Pressure Setpoints in the Cooling and Dehumidifi cation

Reheat Modes.

Description Minimum Default Maximum

Cooling Head Pressure

Setpoint

240 PSI 315 PSI 420 PSI

Reheat Head Pressure

Setpoint

240 PSI 400 PSI 420 PSI

Loading...

Loading...