30

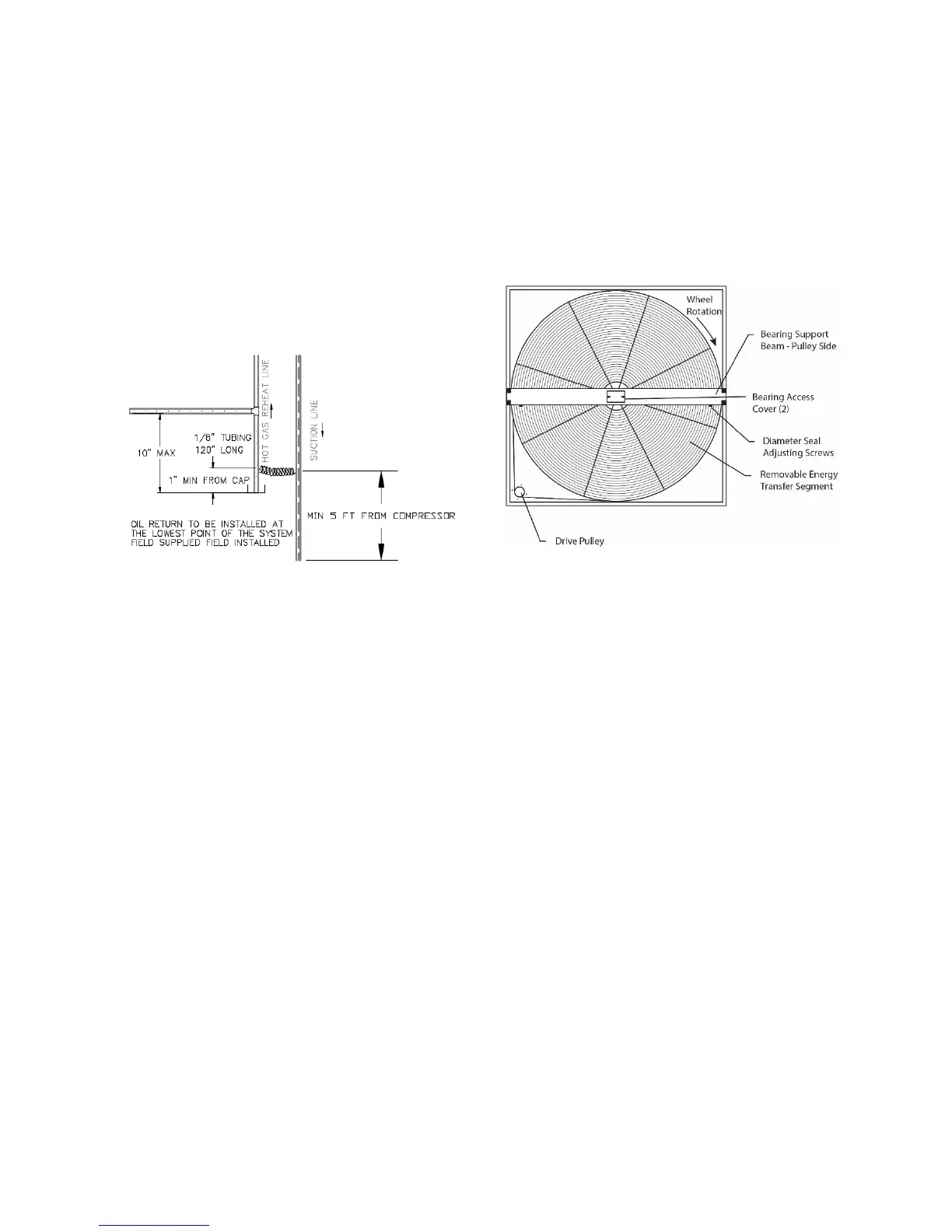

Purge Circuit

The purge circuit is required on hot gas reheat

or hot gas bypass lines. The purge circuit

needs to be field furnished and installed at the

lowest point of the line set.

With this installation, oil drains into the drain

leg of the hot gas reheat line. Oil accumulates

until it reaches the level of the 1/8”OD

capillary tubing.

The combination of capillary action and the

pressure difference between the hot gas

reheat line (high pressure) and the suction

line (low pressure) causes the oil to travel

through the capillary tube into the suction

line of the first circuit to return the oil to the

compressor. The capillary tube connection to

the suction line of the first circuit must be a

minimum of 5 feet from the inlet to the

compressor to allow the oil time to dissipate

into the suction vapor and not slug the

compressor with liquid oil.

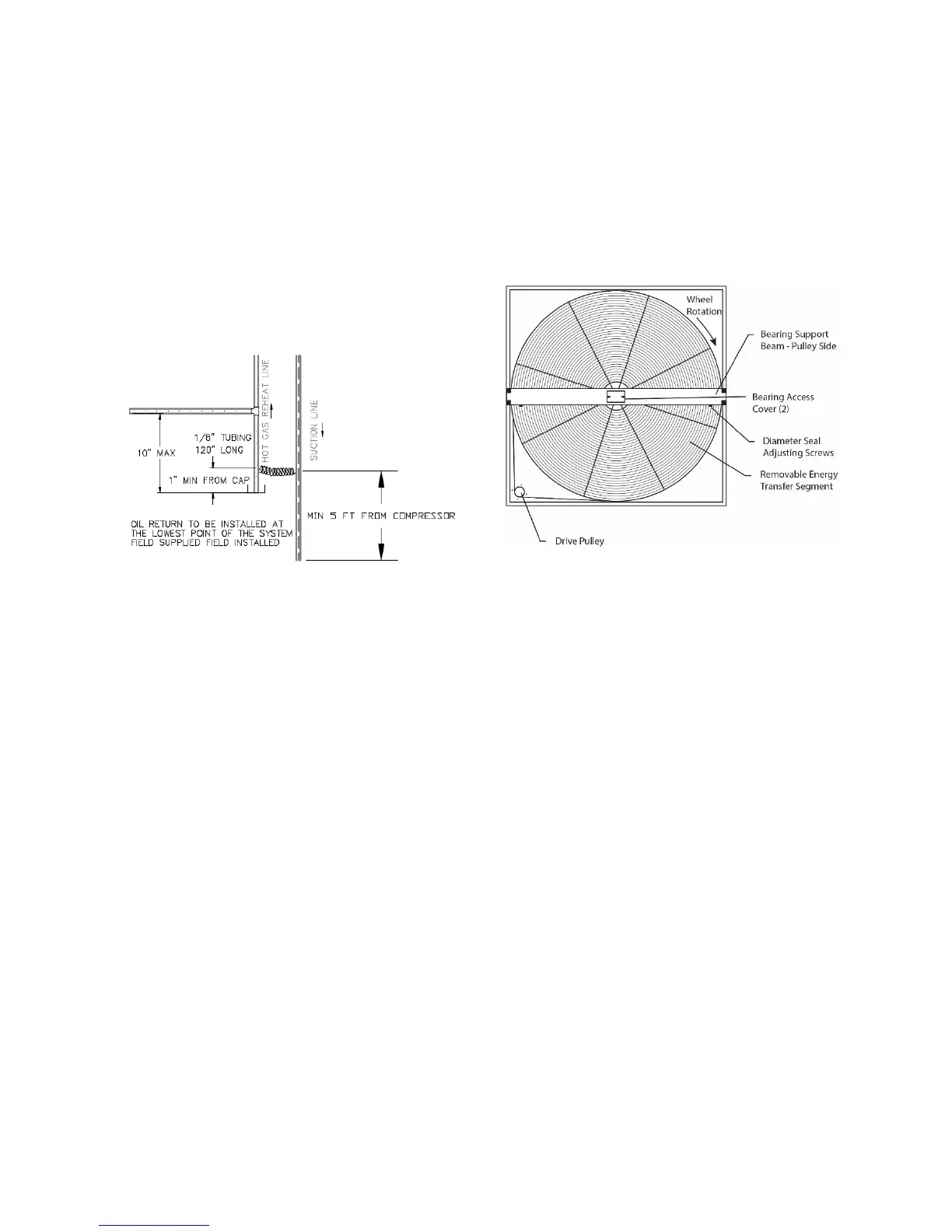

Energy Recovery Units

Some V3 units have been equipped with an

energy recovery wheel. This section is

provided to assure the energy recovery

feature will be properly setup to perform in

accordance with the job specifications for

your particular application.

Figure 18 - Energy Recovery Wheel

The Energy Recovery Cassette consists of a

frame wheel, wheel drive system, and energy

transfer segments. Segments are removable

for cleaning or replacement. The segments

rotate through counter flowing exhaust and

outdoor air supply streams where they

transfer heat and/or water vapor from the

warm, moist air stream to the cooler and/or

drier air stream.

The initial setup and servicing of the energy

recovery wheel is very important to maintain

proper operation efficiency and building

occupant comfort.

Normal maintenance requires periodic

inspection of filters, the cassette wheel, drive

belts, air seals, wheel drive motor, and its

electrical connections.

Wiring diagrams are provided with each

motor. When wired according to wiring

diagram, motor rotates clockwise when

viewed from the shaft/pulley side.

Loading...

Loading...