45

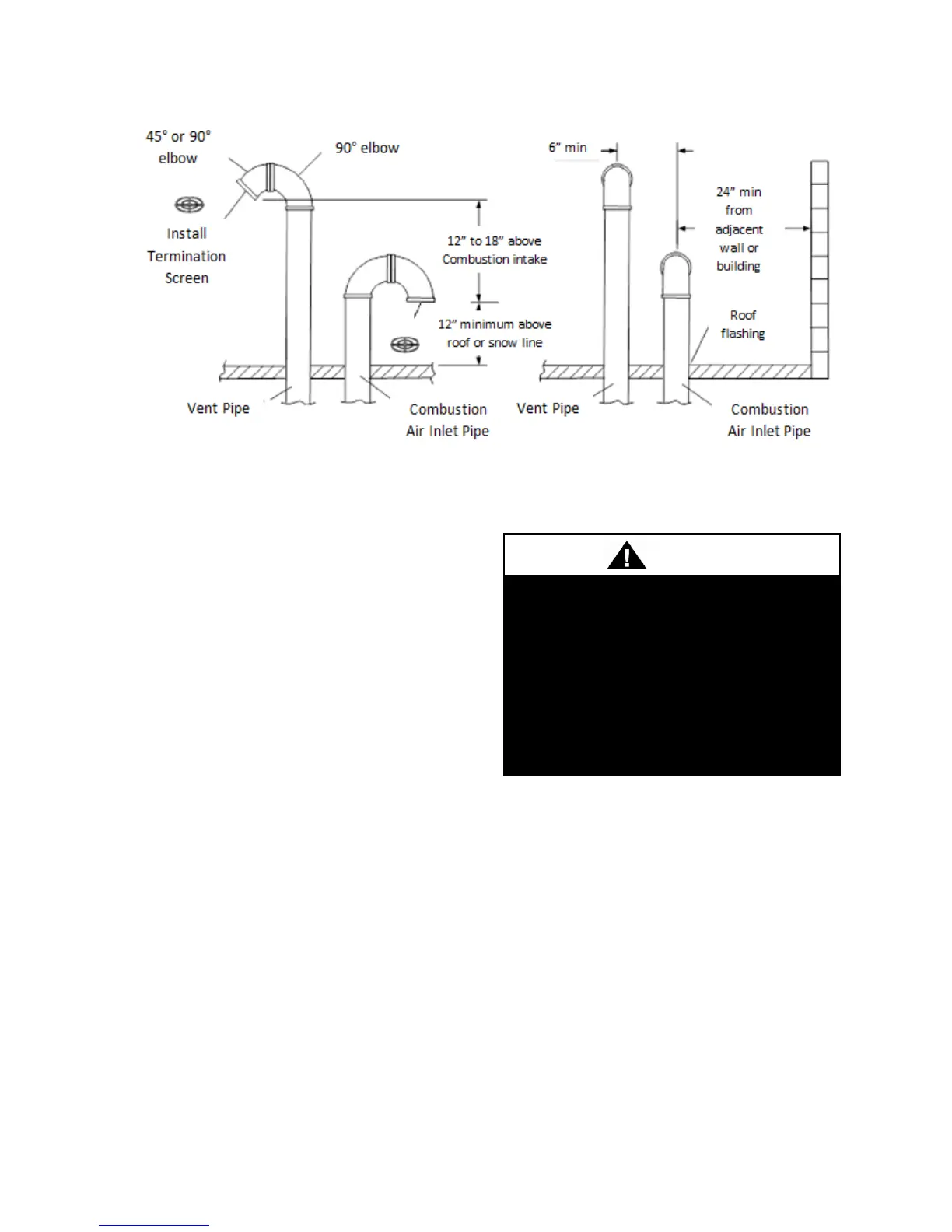

Figure 32 - Separated Combustion Venting

Minimum length before any turns in pipe is

12”.

The vent and combustion air piping must be

properly supported. Horizontal sections must

be installed with an upward pitch of not less

than ¼ in./ft. (21 mm/m) toward the

termination and securely supported every 3ft.

Vent pipe runs through unheated spaces must

be insulated.

The vent drip leg must use reducers from the

outlet to the drain connection to meet

requirements for Canadian installations

(OLC S636). This method is also acceptable

in the US.

Gas Supply, Piping and Connections

Gas piping must be installed in accordance

with local codes, or in the absence of local

code, installation must conform to the current

(United States) National Fuel Gas Code

ANSI-Z223.1/NFPA 54 or the current

(Canada) National Fuel & Propane

Installation Code CSA B149.1 or B149.2.

Gas piping must be sized for the total Btu

input of all units (heaters) serviced by a single

supply. See Table 10 or Table 11 to help size

the gas piping. The gas connection size from

the unit is ½”NPT.

The gas pipe in the unit should be

checked for leaks before startup.

Leak checking is the responsibility of

the installing contractor. All

connections should be checked for

leaks annually. Failure to leak check

could result in fire, explosion, or other

hazardous situations.

Loading...

Loading...