2600T Series Pressure transmitters 266 models | SOI/266-XC 3

Health and Safety

To ensure that our products are safe and without risk to health, the following points must be noted:

1. The relevant sections of these instructions must be read carefully before proceeding.

2. Warning labels on containers and packages must be observed.

3. Installation, operation, maintenance and servicing must only be carried out by suitably trained personnel and in accordance with the information

given. Any deviation from these instructions, will transfer the complete liability to the user.

4. Normal safety precautions must be taken to avoid the possibility of an accident occurring when operating in conditions of high pressure and/

or temperature.

5. Chemicals must be stored away from heat, protected from temperature extremes and powders kept dry. Normal safe handling procedures

must be used.

6. When disposing of chemicals ensure that no two chemicals are mixed.

Safety advice concerning the use of the equipment described in this manual or any relevant hazard data sheets (where applicable) may be obtained

from the Company address on the back cover, together with servicing and spares information.

. . . ABB

This document provides basic instruction for the installation and commissioning of the ABB 2600T pressure transmitter. This transmitter

is connected to a process by means of impulse lines and can measure Pressure, Differential pressure or Absolute pressure.

The measurement is transmitted to a control system by means of a 4-20 mA signal with a superimposed digital signal (Hart) or by

means of a digital transmission protocols (PROFIBUS or FOUNDATION Fieldbus). The measure can also be indicated by means

of one of the (optional) local or remote displays. Instructions for preliminary checks, proper transmitter location, installation, wiring,

power-up and zero calibration (trimming) of the transmitter are listed in the following chapters.

In order to assure operator and plant safety it is essential that the installation is carried out by personnel suitably trained on the local

applicable codes on hazardous location, functional safety, electrical wiring and mechanical piping. Please read these instructions

carefully before installing the transmitter.

The protection provided by the equipment may be impaired if the equipment is used in a manner not specied.

INTRODUCTION

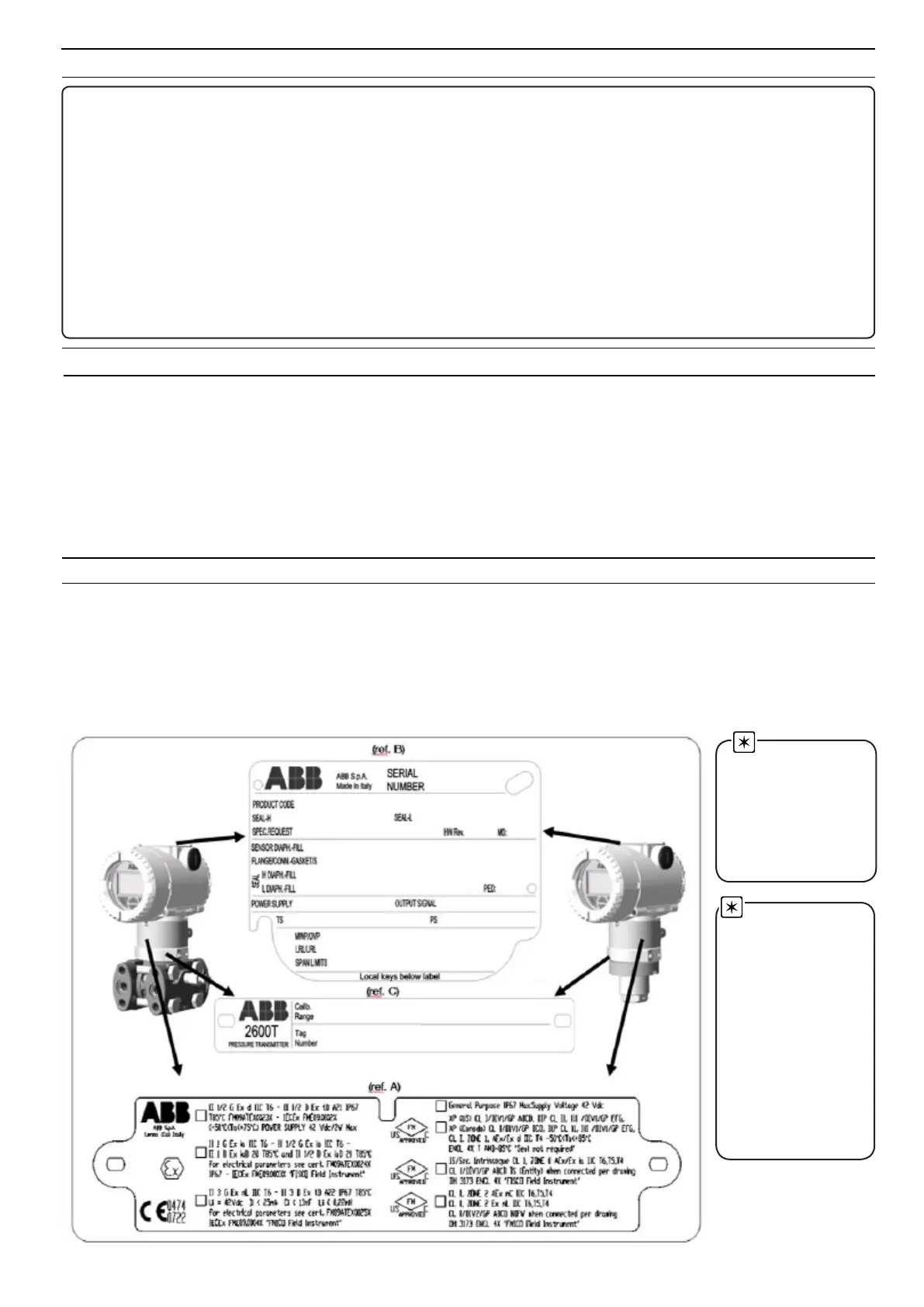

The instrument is identied by the data plates shown in Figure 1.

The certication plate (ref. A) is on the transmitter in order to indicate if it is general purpose or in compliance with hazardous area

regulations.The Nameplate (ref. B) provides information concerning the model code, maximum working pressure, range and span

limits, power supply , output signal, diaphragms material, ll uid, range limit, serial number, maximum process working pressure (PS)

and temperature (TS). Please refer to the serial number when making enquiries to ABB service department. Additionally Tag

plate (ref. C) provides the customer tag number and calibrated range. The instrument may be used as a pressure accessory (category

III) as dened by the Pressure Equipment Directive 97/23/EC. In this case, near the CE mark, there is the number of the notied body

that veried the compliance.

PRODUCT IDENTIFICATION

T h e pi c tu r e

shows pressure tran-

smitters with Barrel

Type housing.

Please consider that

266 product family

includes Din Type

housing, as well.

The certication

plate (ref.A) shown here

on the left may also be

issued for ABB-APR,

32425 Minden, Germany,

with the numbers:

FM09ATEX0068X (Ex d)

FM09ATEX0069X (Ex ia)

FM09ATEX0070X (Ex n)

CE-Identication num-

ber of the notied bodies

to Pressure Equipment

Directive: 0045

to ATEX certication:

0044

Fig. 1 Product identication

Loading...

Loading...