2600T Series Pressure transmitters 266 models | SOI/266-XC 5

Hazardous Area Considerations

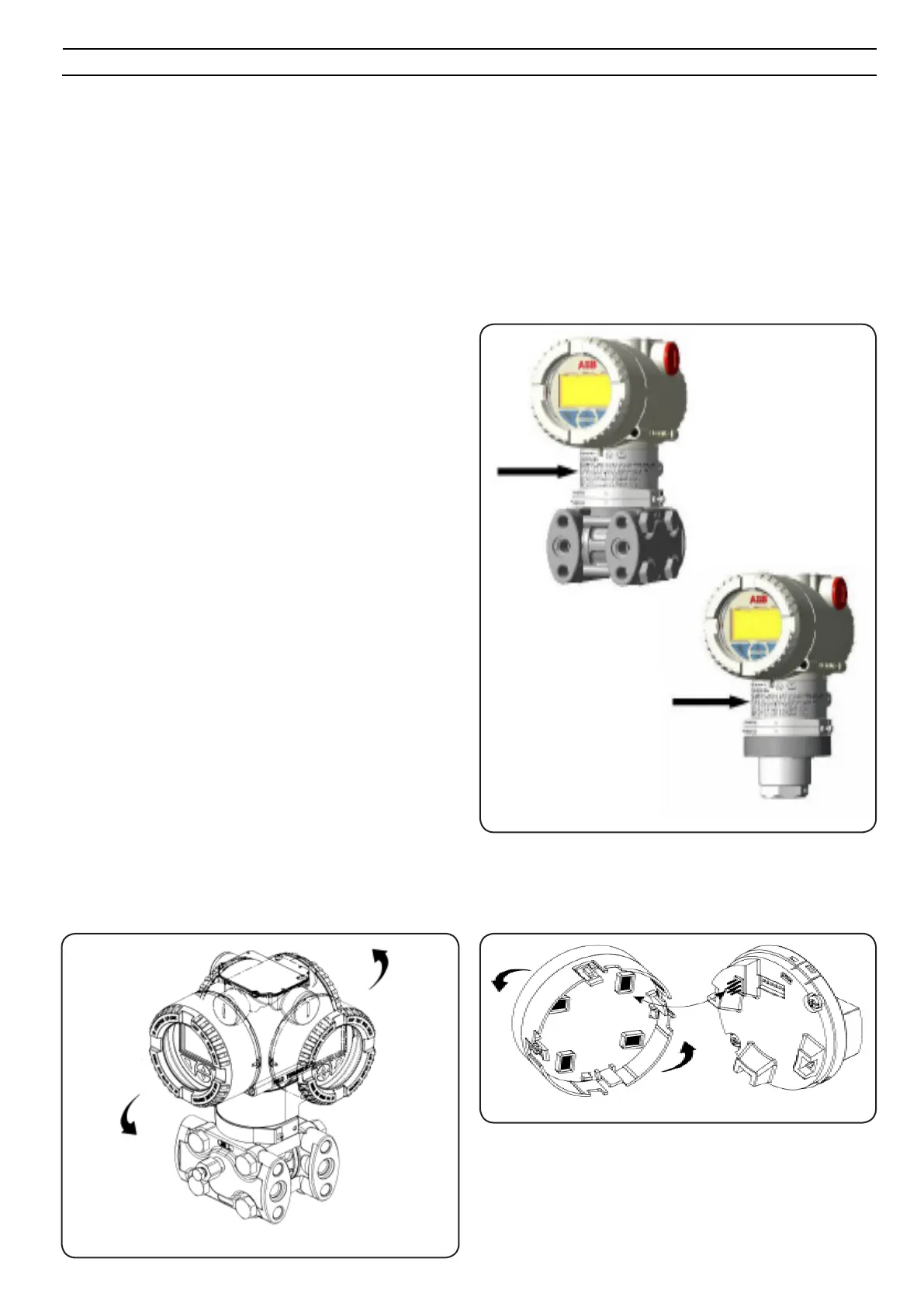

The transmitter must be installed in hazardous area only if it is properly certied. The certication plate is permanently xed on the

side of the transmitter top housing (as shown by the gure).

The 266 Pressure Transmitter Line can have the following certications:

Transmitter

The transmitter can be anged directly to the shut-off valve. A mounting bracket for wall or pipe mounting (2" pipe) available as an

accessory.

Mount the transmitter in such a way that the process ange axes are vertical (horizontal in case of barrel-type aluminum housing) in

order to avoid zero shifts. If the transmitter is installed at an incline, the hydrostatic pressure of the lling uid would exert pressure

on the measuring diaphragm and thus cause a zero shift! A zero point correction would then be necessary. Pressure transmitters can

be mounted in any position.

Seal unconnected process connections on the sensor with the enclosed screw plugs (1/4-18 NPT). For this purpose, use your ofcially

approved sealing material.

ATEX INTRINSIC SAFETY

II 1 G Ex ia IIC T6 and II 1/2 G Ex ia IIC T6

II 1 D Ex iaD 20 T85°C and II 1/2 D Ex iaD 21 T85°C

ATEX EXPLOSION PROOF

II 1/2 G Ex d IIC T6 and II 1/2 D Ex tD A21 IP67 T85°C

ATEX TYPE "N" / EUROPE:

II 3 G Ex nL IIC T6 and II 3 D Ex tD A22 IP67 T85°C

COMBINED ATEX, ATEX FM and FM Canada

See detailed classications

FM Approvals US and FM Approvals Canada:

Explosionproof (US): Class I, Div. 1, Groups A, B, C, D

Explosionproof (Canada): Class I, Div. 1, Groups B, C, D

Dust ignitionproof : Class II, Div. 1, Groups E, F, G

Nonincendive: Class I, Div. 2, Groups A, B, C, D

Intrinsically safe: Class I, II, III, Div. 1, Groups A, B, C, D, E, F, G

Class I, Zone 0, AEx ia IIC T6/T4 (FM US)

Class I, Zone 0, Ex ia IIC T6/T4 (FM Canada)

IEC (Ex):

See ATEX detailed classications

INTRINSIC SAFETY/CHINA

NEPSI approval Ex ia IIC T4-T6

FLAMEPROOF/CHINA

NEPSI approval Ex d IIC T6

GOST (Russia), GOST (Kazakistan), Inmetro (Brazil)

based on ATEX.

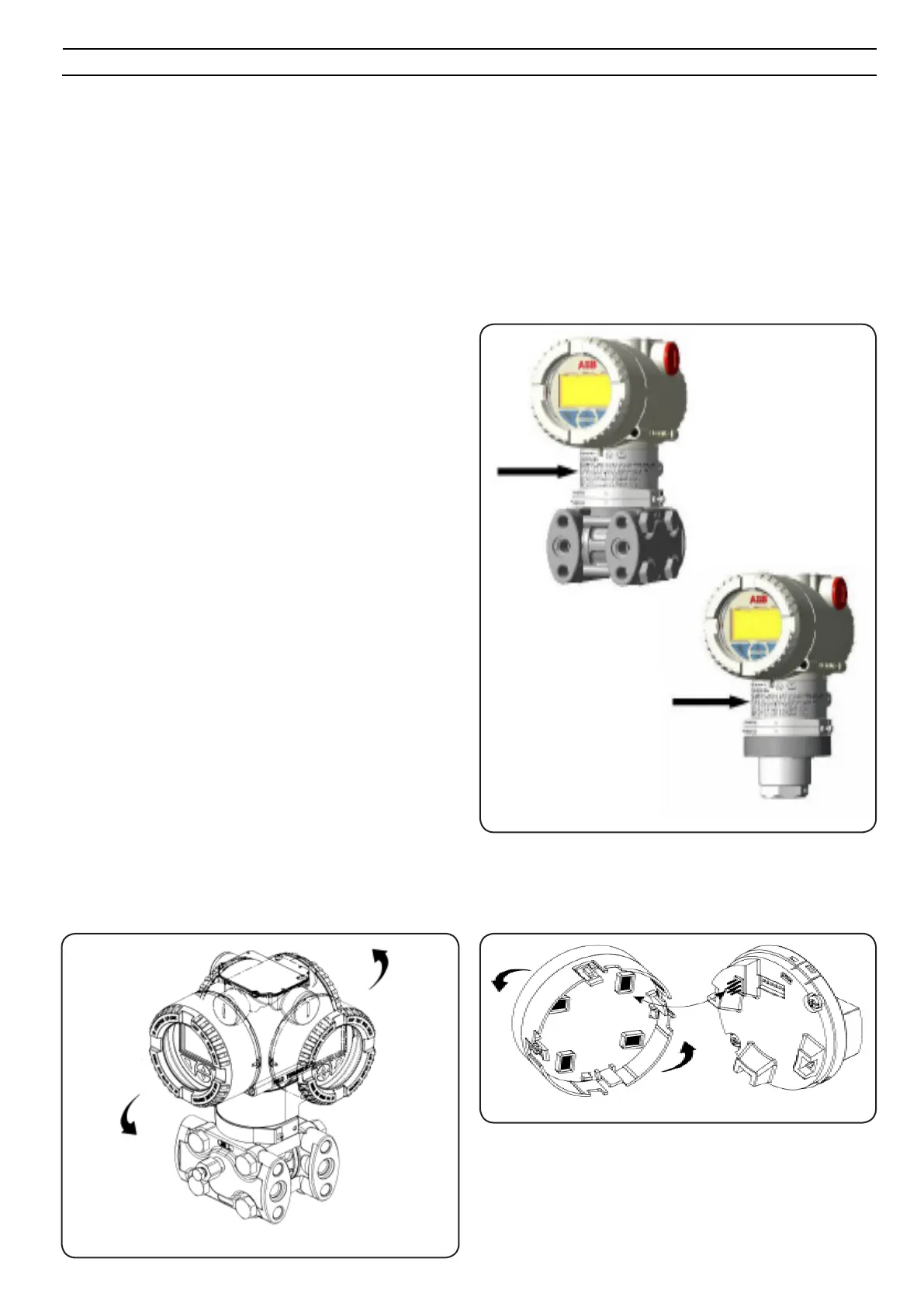

Fig. 3 Housing rotation

Integral Display rotation

In case an optional integral display meter is installed, it is possible

to mount the display in four different positions rotated clockwise

or counterclockwise with 90° steps.

Fig. 4 Display rotation

... INSTALLATION

Housing rotation

To improve eld access to the wiring or the readability of the optional

LCD meter, the electronic housing may be rotated through 360°.

A stop prevents the housing from being turned too far.

Fig. 2 Certication plate

Loading...

Loading...