13

TRANSFORMER COMPONENTS

4.2 Liquid level indicator: general

information

VERIFY CONTACT SURFACE OF THE

CONSERVATOR. IT MUST BE WELL LEVELED

WITH A GOOD DEGREE OF ROUGHNESS (RA=3.2

MICROMETER).

VERIFY AND IN CASE REMOVE ALL WELDING

BURRS TO ENSURE THAT THE WELDING WILL

NOT INTERFERE WITH THE HOUSING FLANGE

HOLES.

DURING THE FLANGE ASSEMBLY, ABB ADVICE

TO APPLY A FEW DROPS OF CYANOACRYLATE

GLUE ON THE GASKET TO FIX IT AT THE OIL

LEVEL FLANGE. THIS ACTION GUARANTEES A

GOOD GASKET POSITIONING AND IT

FACILITATES THE ASSEMBLY

APPLY A SPECIFIC TIGHTENING TORQUE (MAX

20 NM) ON THE NUTS FOLLOWING A CROSS

SEQUENCE.

CAUTION

Depending on the conservator design, the level

gauge can have different values of the parameters R

and S (Fig.16) according to the table 4.

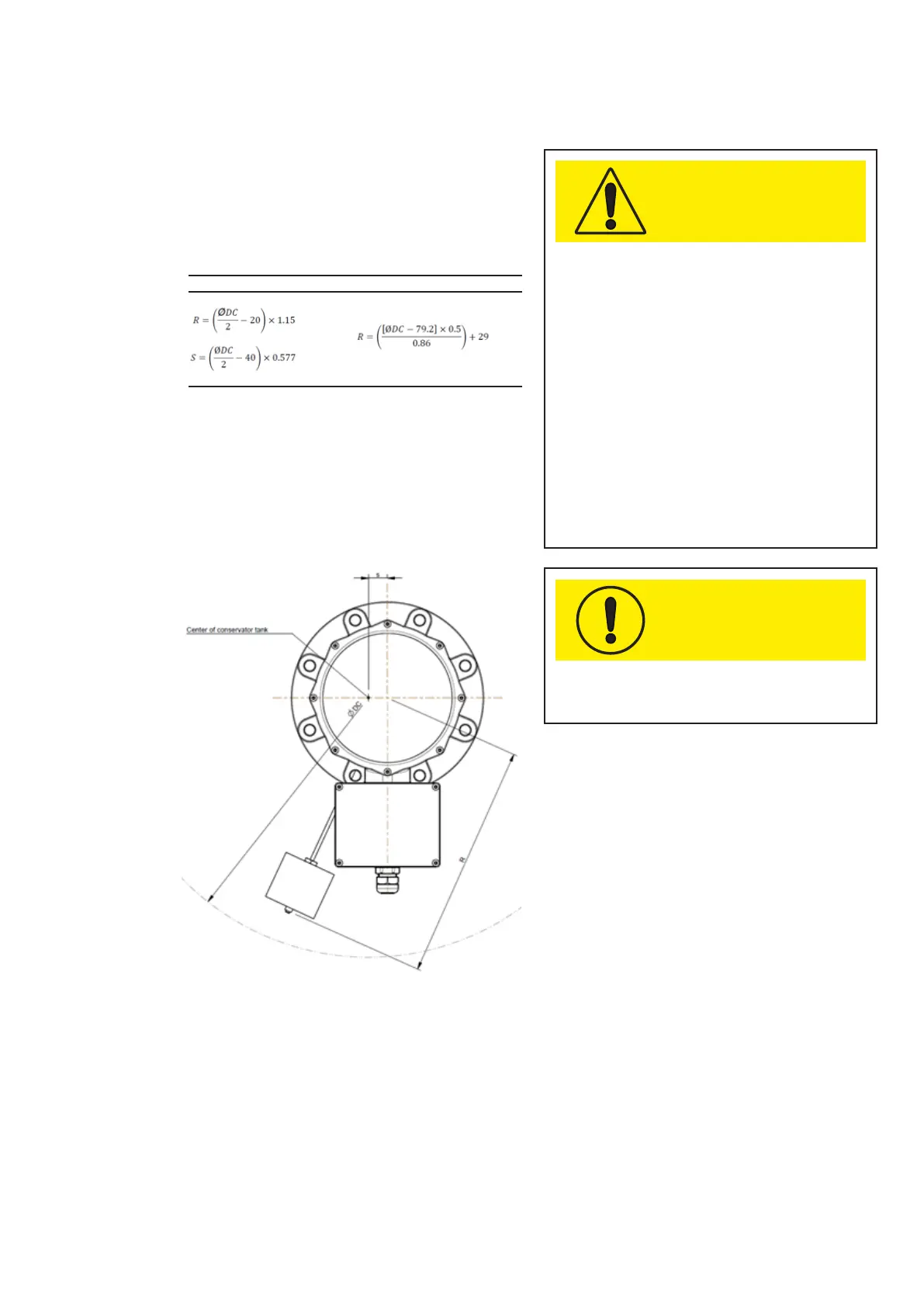

Table 4 a

- “S”: parameter that indicates an offset from the vertical conservator

axis [mm]. It is available for LA (radial) configuration.

- “R”: parameter that indicates the length of the rod [mm]. It is available

for LA (radial) and LB (axial) configurations.

- “ØDC”: conservator diameter [mm].

Figure 16

FOR THE LB CONFIGURATION ABB ADVICE TO FIT

IT IN THE CENTER OF THE CONSERVATOR (S=0

MM)

NOTE

LA LB

—

4. Installation

Loading...

Loading...