3GZF500730-70 rev. C RU-EN 01-2016 | ABB Motors and Generators EN – 47

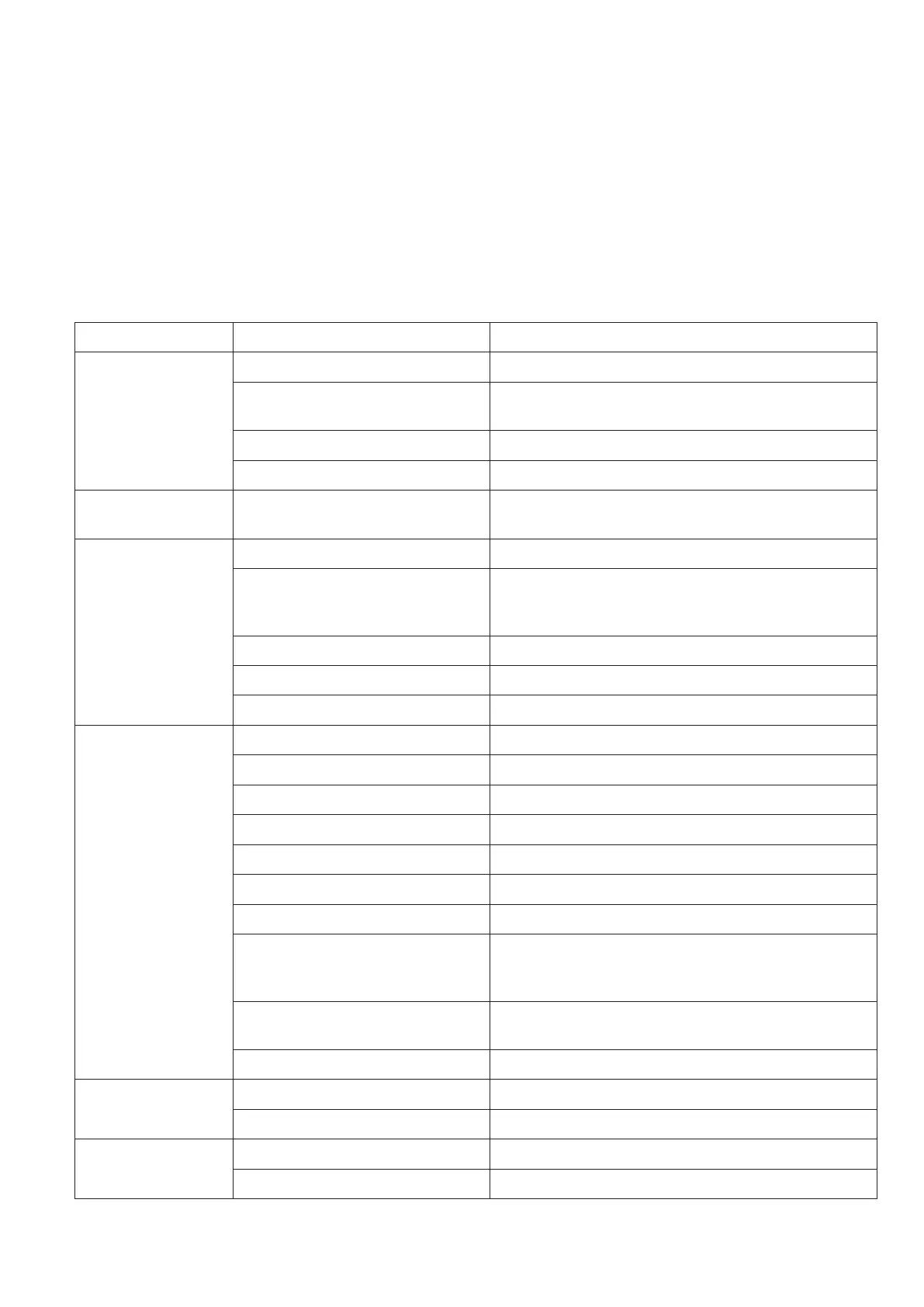

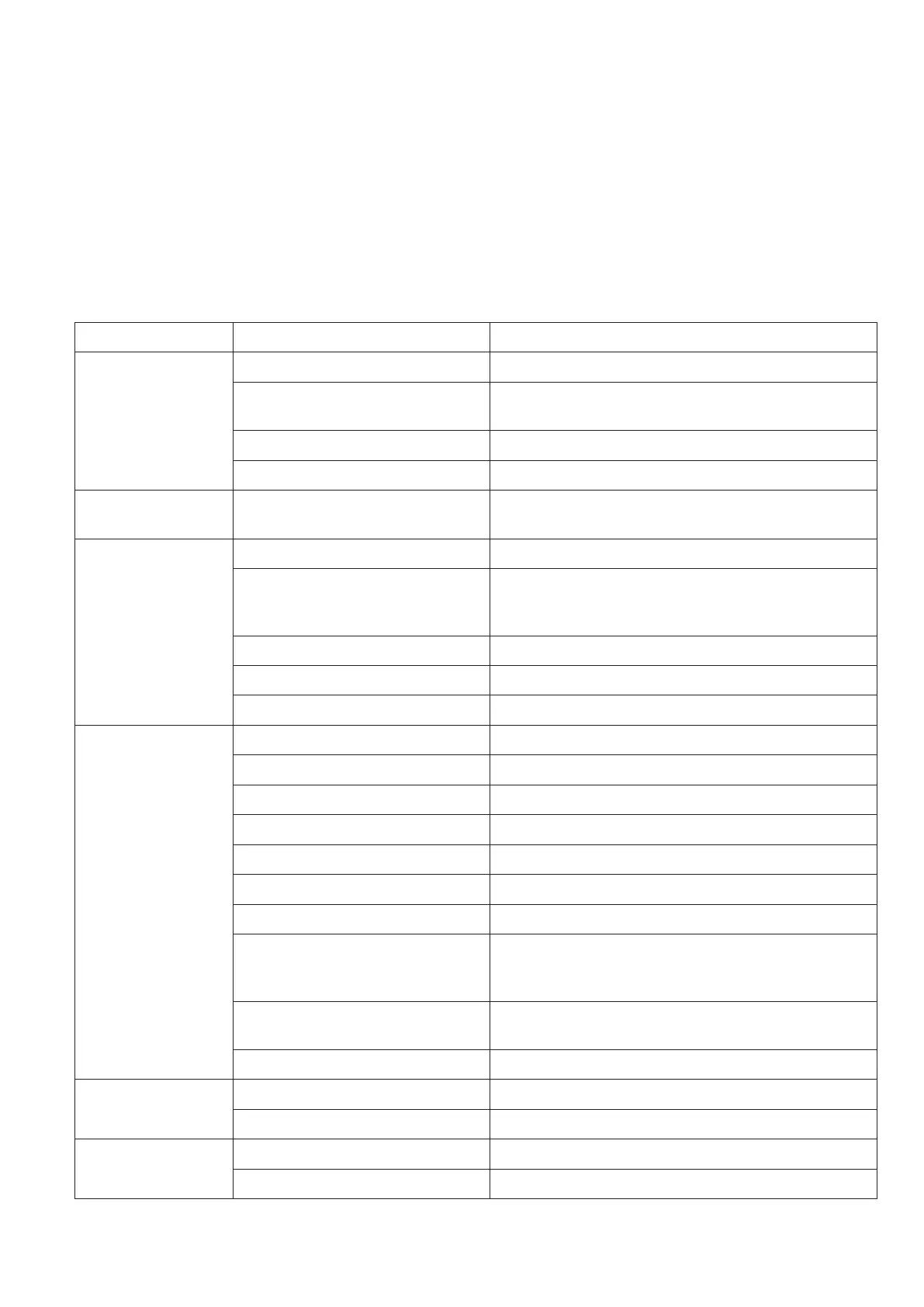

TROUBLE CAUSE WHAT TO DO

Motor takes too long

to accelerate and/or

draws high current

Excessive load Reduce load.

Low voltage during start Check for high resistance. Make sure that an adequate

cable size is used.

Defective squirrel cage rotor Replace with a new rotor.

Applied voltage too low Correct power supply.

Wrong rotation

direction

Wrong sequence of phases Reverse connections at motor or at switchboard.

Motor overheats

while running

Overload Reduce load.

Frame or ventilation openings may

be full of dirt and prevent proper

ventilation of motor

Open vent holes and check for a continuous stream of

air from the motor.

Motor may have one phase open Check that all leads and cables are well connected.

Grounded coil Motor must be rewound.

Unbalanced terminal voltage Check for faulty leads, connections and transformers.

Motor vibrates Motor misaligned Realign.

Weak support Strengthen base.

Coupling out of balance Balance coupling.

Driven equipment unbalanced Rebalance driven equipment.

Defective bearings Replace bearings.

Bearings not in line Repair motor.

Balancing weights shifted Rebalance rotor.

Contradiction between balancing

of rotor and coupling (half key – full

key)

Rebalance coupling or rotor.

Poly-phase motor running single

phase

Check for open circuit.

Excessive end play Adjust bearing or add shim.

Scraping noise Fan rubbing end shield or fan cover Correct fan mounting.

Loose on bedplate Tighten holding bolts.

Noisy operation Air gap not uniform Check and correct end shield fits or bearing fits.

Rotor unbalance Rebalance rotor.

Loading...

Loading...